Product Description

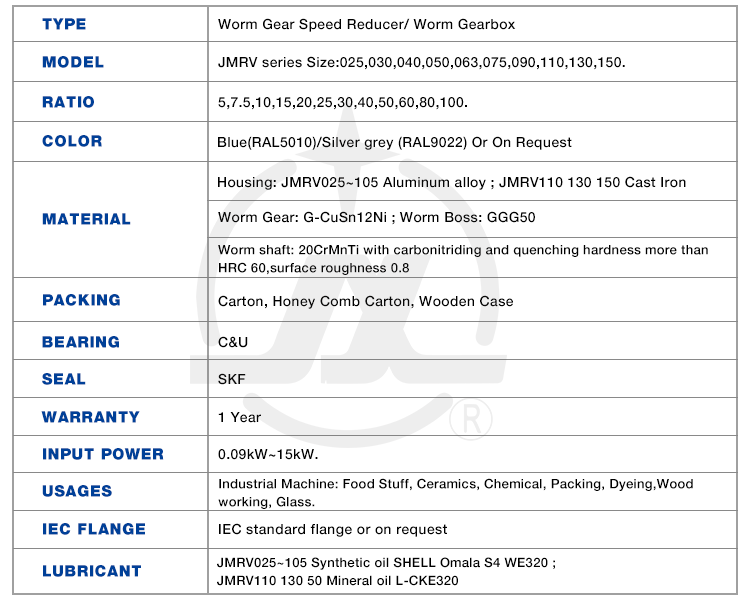

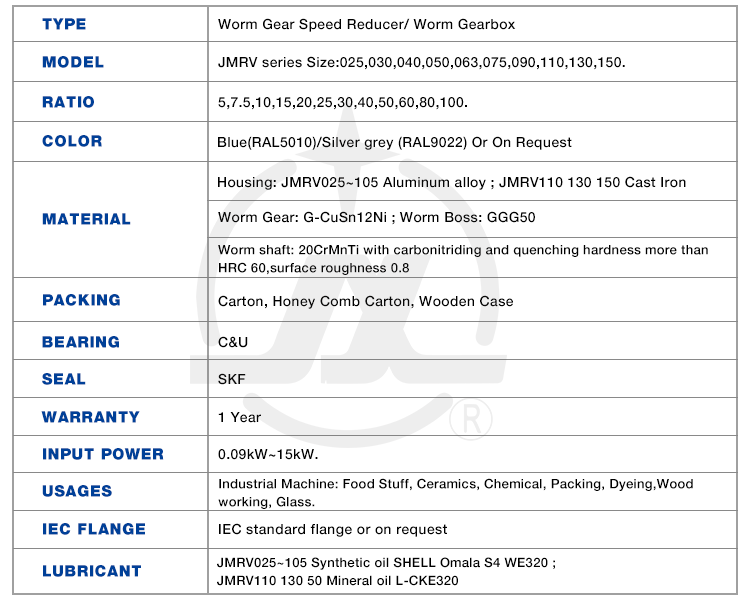

You can kindly find the specification details below:

HangZhou Mastery Machinery Technology Co., LTD helps manufacturers and brands fulfill their machinery parts by precision manufacturing. High precision machinery products like the shaft, worm screw, bushing, couplings, joints……Our products are used widely in electronic motors, the main shaft of the engine, the transmission shaft in the gearbox, couplers, printers, pumps, drones, and so on. They cater to different industries, including automotive, industrial, power tools, garden tools, healthcare, smart home, etc.

Mastery caters to the industrial industry by offering high-level Cardan shafts, pump shafts, and a bushing that come in different sizes ranging from diameter 3mm-50mm. Our products are specifically formulated for transmissions, robots, gearboxes, industrial fans, drones, etc.

Mastery factory currently has more than 100 main production equipment such as CNC lathe, CNC machining center, CAM Automatic Lathe, grinding machine, hobbing machine, etc. The production capacity can be up to 5-micron mechanical tolerance accuracy, automatic wiring machine processing range covering 3mm-50mm diameter bar.

Key Specifications:

| Name | Shaft/Motor Shaft/Drive Shaft/Gear Shaft/Pump Shaft/Worm Screw/Worm Gear/Bushing/Ring/Joint/Pin |

| Material | 40Cr/35C/GB45/70Cr/40CrMo |

| Process | Machining/Lathing/Milling/Drilling/Grinding/Polishing |

| Size | 2-400mm(Customized) |

| Diameter | φ18(Customized) |

| Diameter Tolerance | +0.008/-0.002mm |

| Roundness | 0.003mm |

| Roughness | Ra0.8 |

| Straightness | 0.08 |

| Hardness | HRC20-32 HRC45-55(High-Frequency Quenching) |

| Length | 178mm(Customized) |

| Heat Treatment | Customized |

| Surface treatment | Coating/Ni plating/Zn plating/QPQ/Carbonization/Quenching/Black Treatment/Steaming Treatment/Nitrocarburizing/Carbonitriding |

Quality Management:

- Raw Material Quality Control: Chemical Composition Analysis, Mechanical Performance Test, ROHS, and Mechanical Dimension Check

- Production Process Quality Control: Full-size inspection for the 1st part, Critical size process inspection, SPC process monitoring

- Lab ability: CMM, OGP, XRF, Roughness meter, Profiler, Automatic optical inspector

- Quality system: ISO9001, IATF 16949, ISO14001

- Eco-Friendly: ROHS, Reach.

Packaging and Shipping:

Throughout the entire process of our supply chain management, consistent on-time delivery is vital and very important for the success of our business.

Mastery utilizes several different shipping methods that are detailed below:

For Samples/Small Q’ty: By Express Services or Air Fright.

For Formal Order: By Sea or by air according to your requirement.

Mastery Services:

- One-Stop solution from idea to product/ODM&OEM acceptable

- Individual research and sourcing/purchasing tasks

- Individual supplier management/development, on-site quality check projects

- Muti-varieties/small batch/customization/trial order are acceptable

- Flexibility on quantity/Quick samples

- Forecast and raw material preparation in advance are negotiable

- Quick quotes and quick responses

General Parameters:

If you are looking for a reliable machinery product partner, you can rely on Mastery. Work with us and let us help you grow your business using our customizable and affordable products. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when working with spline shafts?

Working with spline shafts requires adherence to certain safety considerations to ensure the well-being of personnel and the proper functioning of the machinery or equipment. Here’s a detailed explanation:

1. Personal Protective Equipment (PPE):

When working with spline shafts, individuals should wear appropriate personal protective equipment, including safety glasses, gloves, and protective clothing. PPE helps protect against potential hazards such as flying debris, sharp edges, or contact with lubricants.

2. Lockout/Tagout Procedures:

Prior to performing any maintenance or repair work on machinery or equipment involving spline shafts, proper lockout/tagout procedures should be followed. This involves isolating the power source, de-energizing the system, and securing it with lockout devices or tags to prevent accidental startup or release of stored energy.

3. Training and Competence:

Only trained and competent personnel should work with spline shafts. They should have a thorough understanding of the machinery or equipment, including the operation, maintenance, and safety procedures specific to spline shafts. Adequate training and knowledge help minimize the risk of accidents or improper handling.

4. Proper Handling and Lifting Techniques:

When moving or lifting machinery components that include spline shafts, proper techniques should be employed. This includes using appropriate lifting equipment, maintaining a stable posture, and avoiding sudden movements that could cause strain or injury.

5. Inspection and Maintenance:

Spline shafts should be regularly inspected for signs of wear, damage, or misalignment. Any abnormalities should be addressed promptly by qualified personnel. Routine maintenance, such as lubrication and cleaning, should be performed according to the manufacturer’s recommendations to ensure optimal performance and longevity.

6. Correct Installation and Alignment:

During installation or replacement of spline shafts, proper alignment and fit should be ensured. The shafts should be correctly seated and engaged with the mating components, following the manufacturer’s guidelines. Improper installation or misalignment can lead to premature wear, excessive stress, or failure of the spline shafts.

7. Hazardous Environments:

When spline shafts are used in hazardous environments, such as those with flammable substances, extreme temperatures, or high vibrations, additional safety measures may be required. These may include explosion-proof enclosures, temperature monitoring, or vibration damping systems.

8. Emergency Procedures:

Emergency procedures should be established and communicated to all personnel working with spline shafts. This includes knowing the location of emergency stops, emergency shutdown procedures, and the contact information for emergency response personnel.

9. Manufacturer’s Guidelines:

It is essential to follow the manufacturer’s guidelines and recommendations regarding the installation, operation, and maintenance of spline shafts. The manufacturer’s instructions provide specific safety information and precautions tailored to their product.

By taking these safety considerations into account and implementing appropriate measures, the risks associated with working with spline shafts can be minimized. Safety should always be a top priority when dealing with machinery or equipment that incorporates spline shafts.

What materials are commonly used in the construction of spline shafts?

Various materials are commonly used in the construction of spline shafts, depending on the specific application requirements. Here’s a list of commonly used materials:

1. Steel:

Steel is one of the most widely used materials for spline shafts. Different grades of steel, such as carbon steel, alloy steel, or stainless steel, can be employed based on factors like strength, hardness, and corrosion resistance. Steel offers excellent mechanical properties, including high strength, durability, and wear resistance, making it suitable for a broad range of applications.

2. Alloy Steel:

Alloy steel is a type of steel that contains additional alloying elements, such as chromium, molybdenum, or nickel. These alloying elements enhance the mechanical properties of the steel, providing improved strength, toughness, and wear resistance. Alloy steel spline shafts are commonly used in applications that require high torque capacity, durability, and resistance to fatigue.

3. Stainless Steel:

Stainless steel is known for its corrosion resistance properties, making it suitable for applications where the spline shaft is exposed to moisture or corrosive environments. Stainless steel spline shafts are commonly used in industries such as food processing, chemical processing, marine, and medical equipment.

4. Aluminum:

Aluminum is a lightweight material with good strength-to-weight ratio. It is often used in applications where weight reduction is a priority, such as automotive and aerospace industries. Aluminum spline shafts can provide advantages such as decreased rotating mass and improved fuel efficiency.

5. Titanium:

Titanium is a strong and lightweight material with excellent corrosion resistance. It is commonly used in high-performance applications where weight reduction, strength, and corrosion resistance are critical factors. Titanium spline shafts find applications in aerospace, motorsports, and high-end industrial equipment.

6. Brass:

Brass is an alloy of copper and zinc, offering good machinability and corrosion resistance. It is often used in applications that require electrical conductivity or a non-magnetic property. Brass spline shafts can be found in industries such as electronics, telecommunications, and instrumentation.

7. Plastics and Composite Materials:

In certain applications where weight reduction, corrosion resistance, or noise reduction is important, plastics or composite materials can be used for spline shafts. Materials such as nylon, acetal, or fiber-reinforced composites can provide specific advantages in terms of weight, low friction, and resistance to chemicals.

It’s important to note that material selection for spline shafts depends on factors such as load requirements, environmental conditions, operating temperatures, and cost considerations. Engineers and designers evaluate these factors to determine the most suitable material for a given application.

Can you explain the common applications of spline shafts in machinery?

Spline shafts have various common applications in machinery where torque transmission, relative movement, and load distribution are essential. Here’s a detailed explanation:

1. Gearboxes and Transmissions:

Spline shafts are commonly used in gearboxes and transmissions where they facilitate the transmission of torque from the input shaft to the output shaft. The splines on the shaft engage with corresponding splines on the gears, allowing for precise torque transfer and accommodating relative movement between the gears.

2. Power Take-Off (PTO) Units:

In agricultural and industrial machinery, spline shafts are employed in power take-off (PTO) units. PTO units allow the transfer of power from the engine to auxiliary equipment, such as pumps, generators, or farm implements. Spline shafts enable the torque transfer and accommodate the relative movement required for PTO operation.

3. Steering Systems:

Spline shafts play a crucial role in steering systems, especially in vehicles. They are used in steering columns to transmit torque from the steering wheel to the steering rack or gearbox. The splines on the shaft ensure precise torque transfer while allowing for the axial movement required for steering wheel adjustment.

4. Machine Tools:

Spline shafts find applications in machine tools such as milling machines, lathes, and grinding machines. They are used to transmit torque and enable the relative movement required for tool positioning, feed control, and spindle rotation. Spline shafts ensure accurate and controlled movement of the machine tool components.

5. Industrial Pumps and Compressors:

Spline shafts are utilized in various types of pumps and compressors, including centrifugal pumps, gear pumps, and reciprocating compressors. They transmit torque from the driver (such as an electric motor or an engine) to the impeller or rotor, enabling fluid or gas transfer. Spline shafts accommodate the axial or radial movement caused by thermal expansion or misalignment.

6. Printing and Packaging Machinery:

Spline shafts are integral components in printing and packaging machinery. They are used in processes such as web handling, where precise torque transmission and relative movement are required for tasks like tension control, registration, and material feeding. Spline shafts ensure accurate and synchronized movement of the printing and packaging elements.

7. Aerospace and Defense Systems:

In the aerospace and defense industries, spline shafts are utilized in various applications, including aircraft landing gear systems, missile guidance systems, and helicopter rotor systems. They enable torque transmission, accommodate relative movement, and ensure precise control in critical aerospace and defense mechanisms.

8. Construction and Earthmoving Equipment:

Spline shafts are employed in construction and earthmoving equipment, such as excavators, bulldozers, and loaders. They are used in hydraulic systems to transmit torque from the hydraulic motor to the driven components, such as the digger arm or the bucket. Spline shafts enable efficient power transfer and allow for the articulation and movement of the equipment.

These are just a few examples of the common applications of spline shafts in machinery. Their versatility, torque transmission capabilities, and ability to accommodate relative movement make them essential components in various industries where precise power transfer and flexibility are required.

editor by CX 2024-03-06

China best 10W 12V24V90V DC Gear Motor With GearBox with Great quality

10W 12V/24V/90V DC Gear Motor With GearBox

Feature

1. CZPT Motor are made according to CE request

2. Excellent torque characterisitcs

3. Instantaneous start/stop

4. Reliable starting and directional stability

5. Virtually silent running for noise sensitive environments

6. Speed state invariable not effected by voltage under rated frequency

7. Winding will not ruin when motor over loading or abrupt stop running

8. High quality engineering ensures a quiet and long running life

Specification

ModelVoltage(v)Out put Power(w)No-load ParametersLoad ParametersBrush Life(H)Motor Weight(Kg)Speed(r/min)Current(A)Speed(r/min)Torque(mN.m)Current(A)Z2D10-12*121032001.0Max280034220000.7Z2DW10-12*121032001.0Max280034220000.7Z2D10-24*241033000.5Max3000320.920000.7Z2DW10-24*241033000.5Max3000320.920000.7Z2D10-90*957132000.3Max2800340.620000.7Z2DW10-90*957132000.3Max2800340.620000.7Dimension standard

Product show

All the materials of 10W 12V/24V/90V DC Gear Motor With GearBox is very good

Application

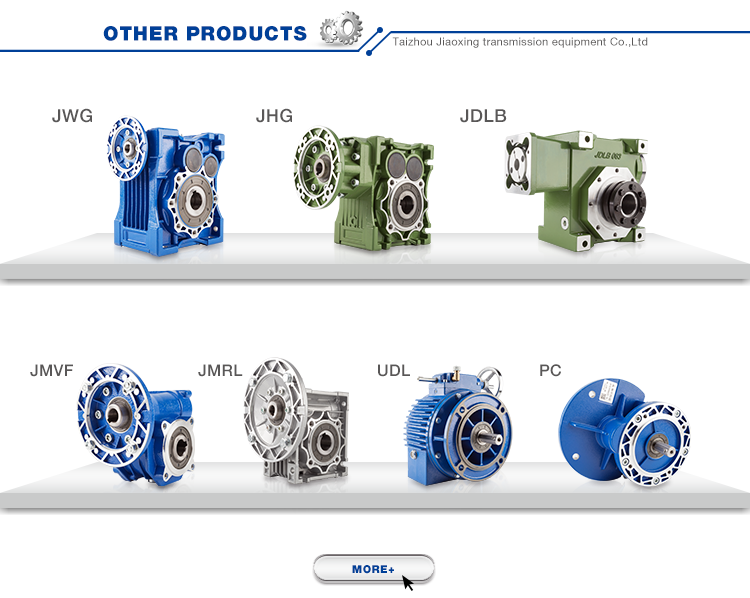

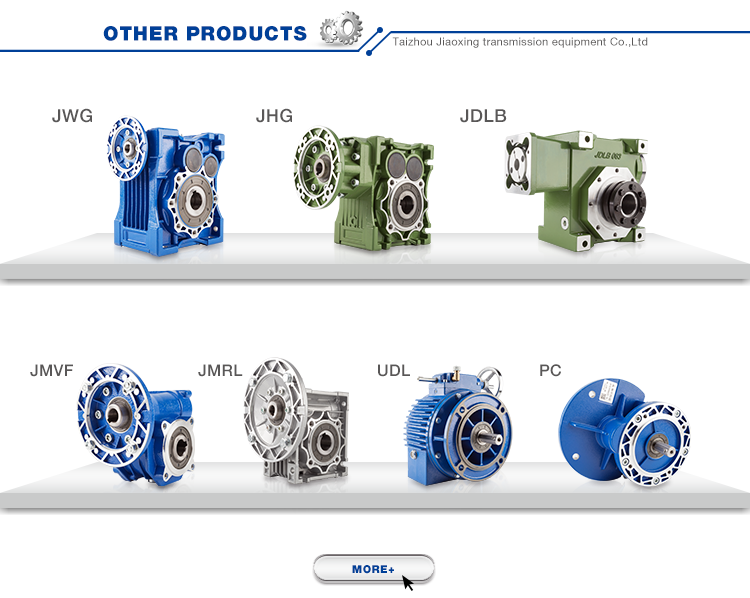

Other products

Packaging & Shipping Packing Method

1.Outer packing: Standard export carton with required shipping marks

2.Inner packing: Waterproof packing with shock absorbing EPE and cardboard surrounded

3.As per the clients requirements

Delivery & Shipment Method

We will ship the items after the payment.

We can ship to you by UPS/DHL/TNT/EMS/Fedex,by air and by sea.

For the Countries & Regions where EMS cannot deliver, Mini Drive Reduction Motor Reducer Case Hydraulic Parts Gear Gearbox pls choose other shipping ways;

Pls contact us directly and we will use your preferred ways

Our Services 1. Free maintenance within 12 months permanent.

2. Professional research and development team.

3. Technical support for installation.

4. Strict quality control system.

5. Customize production.

6. Competitive price.

Company Information CZPT Industries Development Co., Ltd. is a leading manufacturer for factory automation (FA) products ,we focus on power transmission and motion control solutions!

our main production are power transmission products like AC and DC(brush/brushless)gear motor, KBR-20136-00 Agriculture Drive Shaft PTO Shaft Triangular Pipe for tractor stepper motor,high precision planetary gearbox (spur/helical gear)for stepping motor etc

Welcome to visit our website to find more information http://lunyee.en.alibaba.com

FAQ Q1: How much does freight and what shipping method do you support?

A: Shipping is calculated based on the weight of the order and the distance it is travelling; we competitively price each order using our special shipping rates from our partners. For online shoppers you can see a shipping estimate after placing products in your shopping cart and starting to check out. Available online methods are EMS DHL FedEx TNT and so on.

Q2: When will my order be shipped?

A: All regular, sample orders shipped within 7 days after receiving your payment, Custom Orders have their own timeline depending on exactly what you need changed.

Q3: What is your After-Sale Service?

A: we supply free maintenance in warranty of 1 year

B: we supply free solutions during using.

Q4: I do not have the profession designer, Hot Selling Drive Shafts CV Joint Used for Nissan AEL-29178 would you provide the motor drawing?

A: Yes, we have the profession engineer in charge of the production design and research.

http://lunyee.en.alibaba.com

Worm Gear Motors

Worm gear motors are often preferred for quieter operation because of the smooth sliding motion of the worm shaft. Unlike gear motors with teeth, which may click as the worm turns, worm gear motors can be installed in a quiet area. In this article, we will talk about the CZPT whirling process and the various types of worms available. We’ll also discuss the benefits of worm gear motors and worm wheel.

worm gear

In the case of a worm gear, the axial pitch of the ring pinion of the corresponding revolving worm is equal to the circular pitch of the mating revolving pinion of the worm gear. A worm with one start is known as a worm with a lead. This leads to a smaller worm wheel. Worms can work in tight spaces because of their small profile.

Generally, a worm gear has high efficiency, but there are a few disadvantages. Worm gears are not recommended for high-heat applications because of their high level of rubbing. A full-fluid lubricant film and the low wear level of the gear reduce friction and wear. Worm gears also have a lower wear rate than a standard gear. The worm shaft and worm gear is also more efficient than a standard gear.

The worm gear shaft is cradled within a self-aligning bearing block that is attached to the gearbox casing. The eccentric housing has radial bearings on both ends, enabling it to engage with the worm gear wheel. The drive is transferred to the worm gear shaft through bevel gears 13A, one fixed at the ends of the worm gear shaft and the other in the center of the cross-shaft.

worm wheel

In a worm gearbox, the pinion or worm gear is centered between a geared cylinder and a worm shaft. The worm gear shaft is supported at either end by a radial thrust bearing. A gearbox’s cross-shaft is fixed to a suitable drive means and pivotally attached to the worm wheel. The input drive is transferred to the worm gear shaft 10 through bevel gears 13A, one of which is fixed to the end of the worm gear shaft and the other at the centre of the cross-shaft.

Worms and worm wheels are available in several materials. The worm wheel is made of bronze alloy, aluminum, or steel. Aluminum bronze worm wheels are a good choice for high-speed applications. Cast iron worm wheels are cheap and suitable for light loads. MC nylon worm wheels are highly wear-resistant and machinable. Aluminum bronze worm wheels are available and are good for applications with severe wear conditions.

When designing a worm wheel, it is vital to determine the correct lubricant for the worm shaft and a corresponding worm wheel. A suitable lubricant should have a kinematic viscosity of 300 mm2/s and be used for worm wheel sleeve bearings. The worm wheel and worm shaft should be properly lubricated to ensure their longevity.

Multi-start worms

A multi-start worm gear screw jack combines the benefits of multiple starts with linear output speeds. The multi-start worm shaft reduces the effects of single start worms and large ratio gears. Both types of worm gears have a reversible worm that can be reversed or stopped by hand, depending on the application. The worm gear’s self-locking ability depends on the lead angle, pressure angle, and friction coefficient.

A single-start worm has a single thread running the length of its shaft. The worm advances one tooth per revolution. A multi-start worm has multiple threads in each of its threads. The gear reduction on a multi-start worm is equal to the number of teeth on the gear minus the number of starts on the worm shaft. In general, a multi-start worm has two or three threads.

Worm gears can be quieter than other types of gears because the worm shaft glides rather than clicking. This makes them an excellent choice for applications where noise is a concern. Worm gears can be made of softer material, making them more noise-tolerant. In addition, they can withstand shock loads. Compared to gears with toothed teeth, worm gears have a lower noise and vibration rate.

CZPT whirling process

The CZPT whirling process for worm shafts raises the bar for precision gear machining in small to medium production volumes. The CZPT whirling process reduces thread rolling, increases worm quality, and offers reduced cycle times. The CZPT LWN-90 whirling machine features a steel bed, programmable force tailstock, and five-axis interpolation for increased accuracy and quality.

Its 4,000-rpm, 5-kW whirling spindle produces worms and various types of screws. Its outer diameters are up to 2.5 inches, while its length is up to 20 inches. Its dry-cutting process uses a vortex tube to deliver chilled compressed air to the cutting point. Oil is also added to the mixture. The worm shafts produced are free of undercuts, reducing the amount of machining required.

Induction hardening is a process that takes advantage of the whirling process. The induction hardening process utilizes alternating current (AC) to cause eddy currents in metallic objects. The higher the frequency, the higher the surface temperature. The electrical frequency is monitored through sensors to prevent overheating. Induction heating is programmable so that only certain parts of the worm shaft will harden.

Common tangent at an arbitrary point on both surfaces of the worm wheel

A worm gear consists of two helical segments with a helix angle equal to 90 degrees. This shape allows the worm to rotate with more than one tooth per rotation. A worm’s helix angle is usually close to 90 degrees and the body length is fairly long in the axial direction. A worm gear with a lead angle g has similar properties as a screw gear with a helix angle of 90 degrees.

The axial cross section of a worm gear is not conventionally trapezoidal. Instead, the linear part of the oblique side is replaced by cycloid curves. These curves have a common tangent near the pitch line. The worm wheel is then formed by gear cutting, resulting in a gear with two meshing surfaces. This worm gear can rotate at high speeds and still operate quietly.

A worm wheel with a cycloid pitch is a more efficient worm gear. It reduces friction between the worm and the gear, resulting in greater durability, improved operating efficiency, and reduced noise. This pitch line also helps the worm wheel engage more evenly and smoothly. Moreover, it prevents interference with their appearance. It also makes worm wheel and gear engagement smoother.

Calculation of worm shaft deflection

There are several methods for calculating worm shaft deflection, and each method has its own set of disadvantages. These commonly used methods provide good approximations but are inadequate for determining the actual worm shaft deflection. For example, these methods do not account for the geometric modifications to the worm, such as its helical winding of teeth. Furthermore, they overestimate the stiffening effect of the gearing. Hence, efficient thin worm shaft designs require other approaches.

Fortunately, several methods exist to determine the maximum worm shaft deflection. These methods use the finite element method, and include boundary conditions and parameter calculations. Here, we look at a couple of methods. The first method, DIN 3996, calculates the maximum worm shaft deflection based on the test results, while the second one, AGMA 6022, uses the root diameter of the worm as the equivalent bending diameter.

The second method focuses on the basic parameters of worm gearing. We’ll take a closer look at each. We’ll examine worm gearing teeth and the geometric factors that influence them. Commonly, the range of worm gearing teeth is one to four, but it can be as large as twelve. Choosing the teeth should depend on optimization requirements, including efficiency and weight. For example, if a worm gearing needs to be smaller than the previous model, then a small number of teeth will suffice.

China manufacturer & factory supplier for Professional in Bucheon Republic of Korea manufacturers electric gear motor with brake With high quality best price & service

EPG roller chain fulfills or exceeds ANSI expectations and is made in ISO accredited factories. As is the case with our pillow block bearings and ball bearings, our roller chain parts are analyzed prior to cargo to insure quality. The roller chain components and roller chains we provide are pre-stretched to insure you have minimal sag. It also comes with reliable rollers, ensuring that it is of the greatest quality.Because of to our vast item assortment and wealthy ordeals in this market, we are self-assured to offer our customers adaptable and diversified services.

Overview

Swift Specifics

- Relevant Industries:

-

Producing Plant

- Gearing Arrangement:

-

Worm

- Output Torque:

-

15~1700Nm

- Input Velocity:

-

five hundred~2800/min

- Output Speed:

-

5~560/min

- Spot of Origin:Zhejiang, China

- Brand Title:

-

OEM

- Merchandise name:

-

worm drive gear variator reduction motor with brake

- Software:

-

Food Stuff, Ceramics, Chemical, Packing, Dyeing,Wood functioning, Glass.

- Color:

-

Blue(RAL5010)/Silver grey (RAL9022) Or On Request

- Ratio:

-

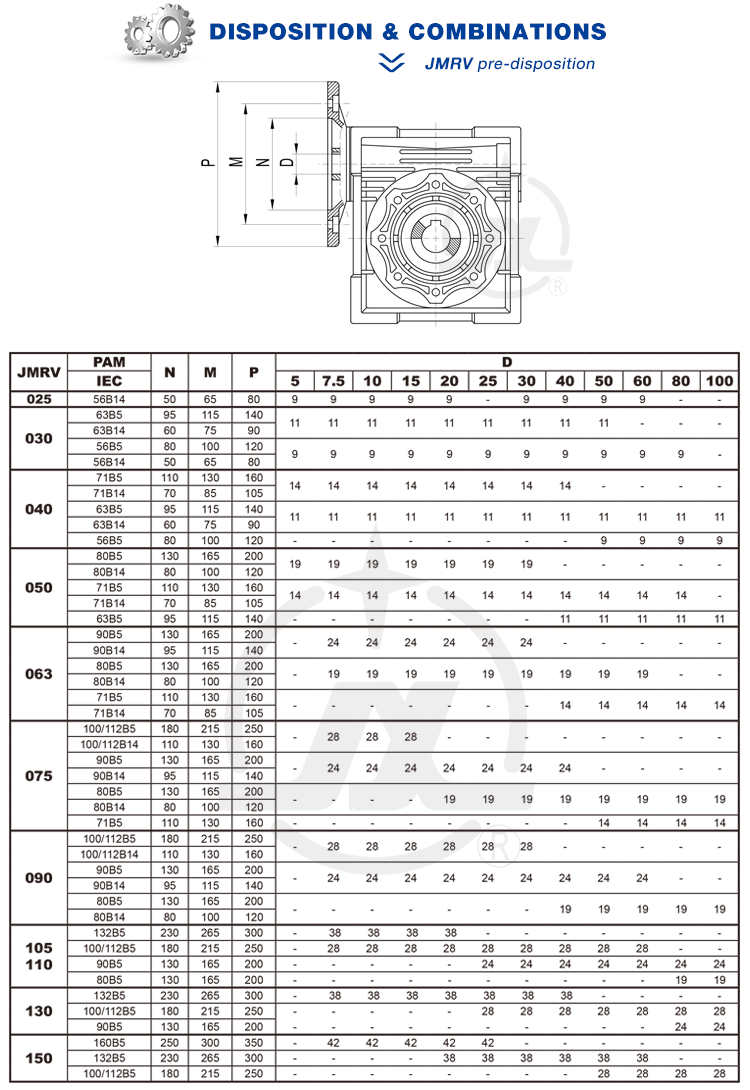

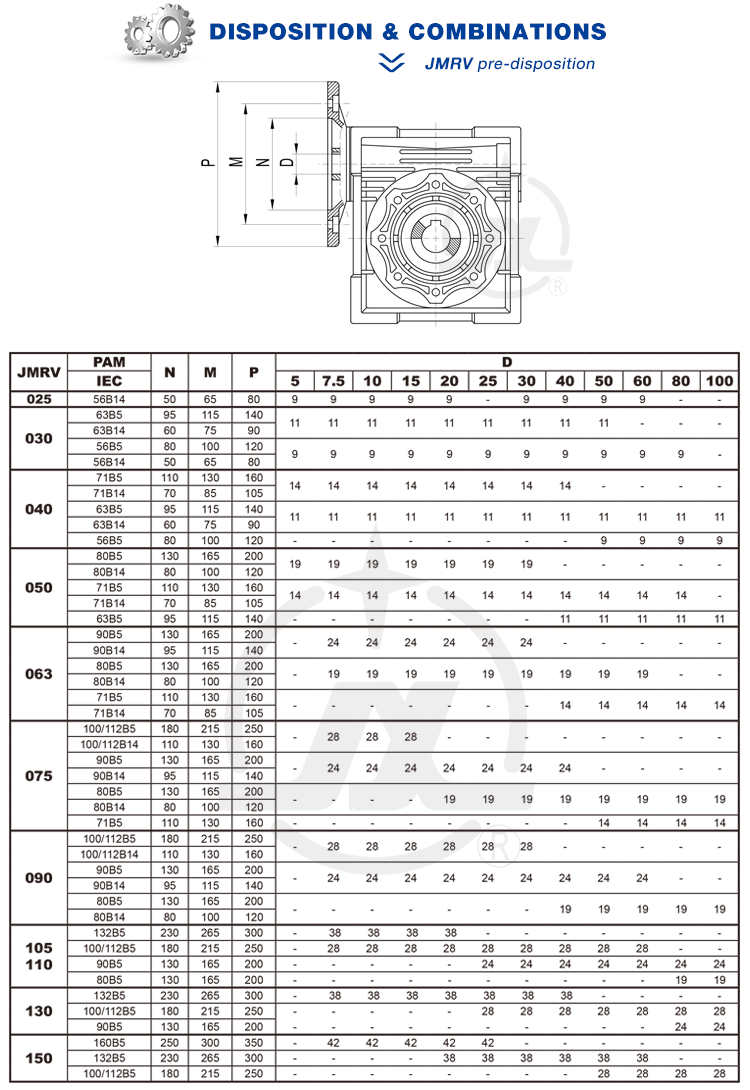

five,7.5,10,15,20,25,30,40,fifty,60,eighty,a hundred.

When the PTO has begun to energy the attachment, steadily boost the throttle until finally you achieve the working speed. The standard operating RPM (revolutions for each minute) for a tractor mounted PTO is 540 RPM, though there are tractor designs that rev larger. Often refer to your specific tractor model for instructions prior to very first-time use.

- Guarantee:

-

1 Calendar year

Supply Potential

- Source Potential:

- 36000 Piece/Items for every Month

Packaging & Shipping

- Packaging Specifics

- Clear box packaging, or colour box packaging, it also can be personalized.

- Port

- Ningbo/Shanghai

EPG major production is of farming 15-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting equipment and components.

Online Customization

The helical-worm gearbox is a specifically minimal-sound travel part. As a compact push device in mix with 3-section AC and servo motors, they are really functional.

Professional manufacturers electric powered equipment motor with brake

Q1. How to select a reduction motor which fulfills our necessity?

A1: You can refer to our catalogue to pick the gearbox or we can assist to pick when you offer

the technical data of output torque, output pace and motor parameter etc.

Q2. How is your price tag? Can you offer any price reduction?

A2: We will give the very best price we can base on your needs and the quantities.

Q3. Do you provide any visiting?

A3: Sure! We sincerely invite you to visit us! We can select you from airport, railway station and so on.

Also, we can prepare housing for you. Please enable us know in advanced.

This autumn. When is the very best time to get in touch with you?

A4: You can contact us by e mail any time, we will reply you as soon as achievable.

Q5. How lengthy will it consider for the direct time?

A5: For our common design, you should refer to the various item internet pages to check out the lead time.

For the OEM/ODM products, please make contact with us for additional details.

Best China manufacturer & factory high quality Textile speed reducer reduction ratio 1.5 : 1-100 : 1 worm motor worm gear worm gearbox supplier With high quality best price

our products are selling well in the American, European, South American and Asian markets. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Bearing:

-

Bronze

- Housing Material:

-

Aluminum alloy

- Product name:

-

DEVO NMRV Series gearbox

- Mounting Position:

-

Flange Motunted

- Input Form:

-

Shaft Input

- Output Form:

-

while the types of yokes for the connection of the PTO shafts with the agricultural implement includes the same above splined yokes and also yokes with recessed button and/or ball collar with:

hollow Shaft Output

- Heat treatment:

-

Carburizing & Quenching

- Color:

-

Blue or silver

- Certificate:

-

ISO 9001

- Warranty:

-

Within our field of work is adapting our reducers from the catalogue to our costumer´s necessity by means of flanges, shafts, extensions, supports, etc. according to the necessities of their machines.

1 Year

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 10 >10 Est. Time(days) 15 To be negotiated

Online Customization

EPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting tools.

Product Description

Introductions of NMRV Series Worm Gear Reducer

The NMRV worm gear reducer is equipped with high quality aluminum alloy casting and it adopts the advanced square box structure which is small in size, light in weight and beautiful in apperance. The worm gear reducer could be matched with other gearboxes to reach a large ratio and torque. What’s more, due to the small size of the gearbox, it is easy to install and maintain. The NMRV worm gearboxes are manufactured with international technical requirements and possess a high technological content which guarantee the high rigity and high torque.

Structure Drawing of NMRV Series

|

|

Advantages of NMRV Worm Gearbox |

||||||

|

Low noise |

This worm gearbox is smooth in transmission which is suitable for working in harsh environment for a long time. |

||||||

|

High efficiency |

With the using of tin bronze worm gear material, this worm gear reducer is low in temperature-rising and fast in heat dissipation. |

||||||

|

High quality |

The reducer made of cast iron which casted with Aluminum mould. It`s good looking and solid, and can be used through the setting |

||||||

Parameter Table of NMRV

HIGH QUALITY HOUSING AND BEARING MATERIAL

The reducer is made of cast iron which casted with Aluminum mould. It`s good looking and solid, and can be used through the setting of multi-azimuth

NMRV SERIES WORM GEAR SPEED REDUCER MOUNTING DIMENSIONS

Dimension Diagram of NMRV 50

Profile of Our Company

Our company is located in the city of Xuzhou, ZJ Province of China. We handle the products of power

transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and

other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields:

machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper

industry, cement industry, cableways and so on.

With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the

peers all over the world. We always innovate for the purpose of better meeting the new demands of our customers and

adapting the new tendency of the industry. Depending on the principles of honestly operating and mutual benefit, We

sincerely look forward to cooperating with you.

Application Field

Packing & Delivery

PACKING AND TRANSPORTION

● Packaging: In order to ensure the integrity of product appearance, we will choose cartons, wooden pallets and wooden pallets according to customer needs.

● Delivery time: Each reducer is manufactured and tested in accordance with strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

● Transportation modal: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

● Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

FAQ

Best China manufacturer & factory All china price parallel shaft gearbox F57 FA57 FAF57 FF57 helical gear reductor with 3hp motor With high quality best price

In 2008, it was awarded with “National Export Commodity Inspection-free Enterprise”.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- ITEM NO:

-

SYF

- Mounting Position:

-

Foot Mounted. Flange Mounted

- Ratio:

-

1.3-58800

- Bearing:

-

NSK Bearing

- Warranty:

-

1-2 Years

- Certificate:

-

ISO9001

- Input speed:

-

0-3000rpm/min

- Output speed:

-

0.1-356rpm/min

- Output torque:

-

0-18000N.m

- Motor power:

-

0.18-11kw

Packaging & Delivery

-

Lead Time

: -

Quantity(Pieces) 1 – 1 Gear-reducer inefficiency converts power to heat. AGMA ( American Gear Manufacturers Assn.) guidelines for worm-gear, helical, and other types of reducers limit the maximum allowable operating temperature to 100°F above ambient, not to exceed 200°F. To stay within these guidelines, worm-gear reducers must be considerably larger than equivalent-rated helical reducers (to dissipate more heat) or rely on auxiliary cooling devices.

2 – 5 6 – 10 >10 Est. Time(days) 5 10 15 To be negotiated

Online Customization

Product Description

F SERIES PARALLEL SHAFT HELICAL GEAR REDUCER

F series parallel shaft helical gear reducer has the characteristics of small volume, light weight, large transfer torque, low energy consumption, high efficiency, low temperature rise, strong load force and various structure forms. Suitable for different installation conditions.

It can be combined with R series, K series, S series, etc. to obtain lower speed and greater torque.

F SERIES STRUCTURE DRAWING

|

OUTPUT SPEED: |

0.1~356 r/min |

|

OUTPUT TORQUE: |

≤18000 N.m |

|

POWER: |

0.18~11kw |

|

MOUNTING TYPE: |

Foot-mounted Foot-mountedEPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting tools. and Hollow- mounted Hollow-shaft B5 Flange-mounted B5 Flange-mounted and Hollow- mounted B14Flange-mounted and Hollow- mounted |

PRECISION BEVEL GEAR

20CrMn Ti material – low carbon alloy steel

Imported gear grinding machine processing, high hardness, stable performance.

Vacuum furnace carburizing heat treatment, carburizing layer uniform.

HIGH QUALITY SHELL MATERIAL

The box body is made of HT200 material,which is cleaned by professional screening and washing equipment to ensure that the inner cavity of the box body is cleaner without iron filings.

HIGH QUALITY OUTPUT SHAFT

New standard axle, multi-precision machining, through rigorous dynamic and static balance test, to ensure low noise and smooth operation of reducer

PROFESSIONAL AIR TIGHTNRSS TEST

Before spraying each reducer, air tightness test is needed to minimize the occurrence of oil leakage and air leakage. Ensure the long life and good operation of the reducer.

F SERIES HELICAL GEAR UNITS OVERVIEW:

●Parallel output,structure compact,carrying bigger torque,operation stable,voice low,lifetime long.

●Mounting mode :foot-mounted,flange-mounted,torque arm-mounted.

●Ratio:ratio of 2-stage is 8.1-191,ratio of 3-stage is 28.2-273,ratio of combination is up to 18509.

●For 2-stageOur PTO drive shafts enable the user easy maintenance. The greasing nipples on standard crosses are positioned under angle to enable the user better access. Easier access is also possible because of the flexible cone. We listened to the wishes of our customers and placed the greasing nipple at wide-angle PTO’s into the cross bearing. The other novelty, we introduced with wide-angle PTO drive shafts is in line greasing. We wanted to additionally simplify the maintenance and extend the lifespan of joints. basic type geared,rotation direction of input shaft is the same that of output shaft;for 3-stage basic type geared,their directions are reverse;for combination,please contact Ever Power.

●Output mode:hollow shaft output or solid shaft output.

●Average efficiency: 2-stage 96%, 3-stage 94%,combination 85%.

F SERIES PARALLEL SHAFT HELICAL GEAR REDUCER MOUNTING DIMENSIONS OUTPUT SHAFT DIMENSIONS

F foot shaft mounting parallel helical gear reducer

FA hollow shaft mounting parallel shaft helical gear reducer

FF flange shaft mounting parallel shaft helical gear reducer

Our Company

HANGZHOU EVER-POWER GROUP, ONE OF THE BIGGEST GEARBOX FACTORY IN CHINA, ELECTROMECHANICAL EQUIPMENT SUPPLY STATION

Our company is located in the city of HangZhou, ZheJiang Province of China.

We handle the products of power transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields: machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper industry, cement industry, cableways and so on.With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers all over the world.

Furthermore, the R&D investment are annually increasing for the purpose of better meeting the new demands of our customers and adapting the new tendency of the industry.

Depending on the principles of honestly operating and mutual benefit, We sincerely look forward to cooperating with you.

Application area

Certifications

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In order to ensure the integrity of product appearance, we will choose cartons, wooden pallets and wooden pallets according to customer needs.

●Delivery time: Each reducer is manufactured and tested in accordance with strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

●Transportation mode: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

●Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

FAQ

Q1: Are you a trading company or a manufacturer ?

A: We are a manufacturer in ZheJiang Province, China. Our company owns the ability of manufacturing, processing,designing and R&D. We welcome your visit.

Q2: How we select models and specifications?

A: According to the specific details of the demands from the part of enquiry, we will recommend the products’ models upon synthesizing the factors of field of products usage, power, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our prices are always competitive. If the customer can place a large order, we surely will allow discount.

Q4: How long should I wait for the feedback after I send the enquiry?

A4: We will reply the enquiries without any delay, 12 hours at most.

Q5: What is your product warranty period?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes being used?

A: Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

Hot-sale Product

Best China manufacturer & factory Hot selling lower price 1 240 rpm double shaft 1 hp worm gear motor with reduction gear With high quality best price

Due to our sincerity in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements,a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Construction works

- Gearing Arrangement:

-

worm

- Output Torque:

-

15~1700Nm

- Input Speed:

-

500~2800/min

- Output Speed:

-

5~560/min

- Brand Name:

-

OEM

- Product name:

-

worm gear motor with reduction gear

- Application:

-

Food Stuff, Ceramics, Chemical, Packing, Dyeing,Wood working, Glass.

- Color:

-

Blue(RAL5010)/Silver grey (RAL9022) Or On Request

- Ratio:

-

5,7.5,10,15,20,25,30,40,50,60,80,100.

- Warranty:

-

1 Year

Supply Ability

- Supply Ability:

- 36000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Transparent box packaging, or color box packaging, it also can be customized.

- Port

- Ningbo/Shanghai

Online Customization

Hot selling lower price 1/240 rpm double shaft 1 hp worm gear motor with reduction gear

Q1.How to choose a worm gear motor which meets our requirement?

A1: You can refer to our catalogue to choose the gearboAdhering to “Survival by Quality, Development by Technology & Credit”, The company will constantly improve product performance to meet the increasing customer requirements in the rigorous style of work. x or we can help to choose when you provide

the technical information of output torque, output speed and motor parameter etc.

Q2.How is your price? Can you offer any discount?

A2: We will give the best price we can base on your needs and the quantities.

Q3.Do you offer any visiting?

A3: Yes! We sincerely invite you to visit us! We can pick you from airport, railway station and so on.

Also, we can arrange housing for you. Please let us know in advanced.

Q4.When is the best time to contact you?

A4: You can contact us by email any time, we will reply you as soon as possible.

Q5.How long will it take for the lead Our stepperSFI M100 PTO AdapterAs a precautionary measure, it is a good idea to purchase a PTO adapter to ensure compatibility with your particular tractor model. and BLDC motors, linear actuators and linear positioning drives, in sizes beginning at 10 mm, together with a variety of gearboxes and encoders, combine into a modular system with over 4000 possible combinations. In addition, you can choose from a range of shaft, flange and connector types that rapidly and reliably connect to existing device architecture. The performance and resonance behavior of EPG motors is optimized by intelligent motor controllers that meet the latest technology standards.time?

A5: For our standard model, please refer to the different product pages to check the lead time.

For the OEM/ODM products, please contact us for further information.