Our standard 700 Series – the heart of Ever-Power quickness reducer product line – has been serving industry reliably for over 10 years. Its proven modular style has set the sector standard for functionality and is the most imitated product in today’s worm gear swiftness reducer market. But why settle for a knock-off when you’re able to have the original – from Ever-Power.

Specifications

11 basic single reduction sizes

8 basic dual reduction sizes

1/6 – 25 HP

5:1 – 100:1 ratios single reduction

100:1 – 3600:1 ratios double reduction

Non-flanged, NEMA C-face quill, and coupled input styles

Projecting and hollow result shafts

Projecting diameters from 1/2″ to 2-1/4″

Hollow result bore diameters from 5/8″ to 3-7/16″ (with over 20 bore sizes in share)

Product Features

The 700 Series’ huge oil reservoir provides efficient heat dissipation and lubrication for longer operating lifestyle.

Its multi-position mounting flexibility allows for installation in practically any position.

Housings are straddle-milled, top and bottom, for precise alignment of horizontal and vertical bases.

Internal baffles assure positive, leak-free venting.

The 700 Series’ rugged housing, fabricated of fine-grained, gear-quality cast iron, provides optimum strength for optimum durability, in addition to greater precision during worm and gear alignment.

Ever-Power 700 Series high-strength bronze worm equipment is straddle mounted between heavy-duty tapered roller bearings to increase thrust and overhung load capacities, sizes 713-760.

Our 700 Series’ high-strength steel output shaft assures capacity for high torque and overhung loads.

Pipe plugs allow easy fill up, level, and drain in virtually any mounting position.

The 700 Series’ super-finished oil-seal diameters on both input and output shafts extend seal existence.

Both 2D and 3D CAD drawings are available in our eCatalog.

Ever-Power worm gearboxes possess earned a status to be a business benchmark worldwide. Our success originated from our relentless drive for quality with state-of-the-artwork technology, all and will be offering worm gearboxes are affordable prices. High versatility accorded through a wide choice of mounting options, shaft configurations and electric motor interfaces, makes the Ever-Power worm gearbox the default choice for the market. The helical-worm and the double-worm edition, with or without the torque limiter, add up to the advantage, creating an extremely versatile drive system.

Ever-Power Worm gearboxes provide high torque with low speed gear ratio. Being basic and compact in style, these gears can perform higher gear ratio compared to the helical gears. These worm decrease gears having screw type qualities act like helical gears, but its helix angle is typically comparatively larger) and its body is normally quite lengthy in the axial path. The gears in these gearboxes can be right or left-handed depending upon the purpose.

Mounting choice include universal housing, part flanges, foot (horizontal and vertical), shaft mounted with torque arm. Available in Solid shafts (single or dual), with torque arm or torque limiter.

Worm reduction gears features

Principles

A worm gear is a type of interlocking gear composed of a worm shaft and worm wheel. The worm is definitely shaped like a screw and the worm wheel is certainly a type of gear machined to have a tooth profile with the same configuration.

The operation of a worm gear is similar with that of a bolt and nut. The principle is equivalent to a nut that is fixed to ensure that it cannot rotate and therefore progresses in the axial path when the bolt can be turned.

The look of a worm gear is thought of through the relationship between the rack and spur gear on the center plane of the worm wheel.

Features

High reduction ratio One rotation of the worm rotates the worm wheel by one tooth. For this reason, in a 1 speed decrease gears, the wheel can be manufactured therefore that it’ll be rotated 1/60 (1/120 in special applications).

Orthogonal shaft The shafts are aligned orthogonally due to the structure. This feature makes it possible to layout the turning transmission direction at the right angle.

The arbitrariness of the rotation direction The screw direction of the worm can be clockwise or counterclockwise (generally clockwise). You’ll be able to change the rotation path of the worm wheel by changing the screw direction.

A wide variety of shaft layouts The wide selection of shaft layouts is one of the features of interlocking gears.For instance, right shaft output, remaining shaft output, dual shaft input and dual shaft output, etc., combine for a complete of 14 types (Physique 2) and, if attachment orientations are included, you’ll be able to select from over 40 layouts.

Low noise, low vibration The interlocking of the worm and worm wheel is certainly characteristic because the contact is certainly linear and the relative slide is fantastic. In comparison with rolling power transmission, noise and vibration are extremely low. For this reason, this technology is utilized to drive medical apparatus, elevators and escalators, etc.

The primary specifications of worm reduction gears

MA Series(Small)

Center distance(mm) 32,40

Reduction ratio 10,20,30,40,50,60

Input capacity(kW) 0.1~1(at an input of 1800 rpm)

Output torque(N・m) 20~66

Input speed(rpm) 0~1800

MA Series(Medium)

Center distance(mm) 50,63,80,100,125,140,160

Reduction ratio 10,15,20,25,30,40,50,60

Input capacity(kW) 0.4~30(at an input of 1800 rpm)

Output torque(N・m) 900~3570

Input speed(rpm) 0~1800

S Series

Center distance(mm) 50,60,70,80,100,120,135,155,175,200,225,250,300,350,400,450,500

Reduction ratio 10,15,20,25,30,40,50,60

Input capacity(kW) 0.3~255(at an input of 1800 rpm)

Output torque(N・m) 50~56600

Input speed(rpm) 0~1800

Key points when selecting a worm reduction gears

Selection

When selecting a worm reduction gears, the procedures for selecting the right gear are described in the maker catalogs and the series and models ought to be selected according to those procedures. Particular care should be taken in important areas such as selecting the load index, calculating the overhang load and examining heat rated capability from the manufacturer.

Cautions during use

When utilizing a worm reduction gears, the heat produced during the initial period of use is high and running-in operation at 1/4, 1/2 and 3/4 of rated torque for eight hour periods is paramount to sufficiently attaining the performance of the worm reduction gears.

Maintenance and inspection

After completing running-in operation (approximately 50 hours), it’s important to improve the lubricating oil and to change the lubricating oil after that about 1 time per year according to the procedure manual offered by the manufacturer.

Product Description

The Worm Decrease Gear Box is supplied by our company is of high-quality. Our products are made through the use of premium quality material and advance technology at our vendors end. These are widely used in various sectors. Our products are easily available at a very low market prices.

Motor Mount Frame Options

TEC Motors, worm decrease gearbox.

Option A-160 B5 Body, Flange Mount.

Option B-132 B14 Frame, Face Mount.

Option C-100/112 B5 Frame, Flange Attach.

High efficiency and secure operation. High load capacity and overload functions. Result Torque = (Power (kW) x 9550 (Constant))/ Gearbox output speed (rpm).

Higher ratios on request dependent on service factor (40:1, 50:1, 60:1, 80:1, 100:1)

DESCRIPTION

Wormgears of the VF series are milestones for the market worldwide. They succeeded in combining uncompromising quality with stateoftheart technology amd renown price  effectiveness.Absolute versatility is given by the wide choice of several installation options, shaft configurations and engine interface, all offered as regular. The helicalworm and the doubleworm edition, with or without the torque limiter, also accumulate, creating an extremely versatile drive system.

effectiveness.Absolute versatility is given by the wide choice of several installation options, shaft configurations and engine interface, all offered as regular. The helicalworm and the doubleworm edition, with or without the torque limiter, also accumulate, creating an extremely versatile drive system.

ADDITIONAL INFORMATION

AMP

0.42 A

EFFICIENCY

84%

HP

0.12

KW

0.09

RATIO

7

RPM

200

TEMPERATURE RATING

20 degree C TO 80 degree C

TORQUE

4 Nm

HSN

8483.40.00

WARRANTY PERIOD

12 Months

The worm reduction gears can be found in two series: X and H.

The series X, having a worm and worm wheel set, comes in versions XA with shaft and XF-XC with mounting provisions for motor.

Version XF (bell housing + coupling) provides great versatility to match a broad selection of applications and provides higher efficiency compared to the compact series XC, where the emphasis is on space performance.

Series H offers the same features because series X with an added plus: a spur gear pre-stage at the input end provides higher performance and a broader range of ratios than the X series.

Body sizes 110 and 90 feature a cast-iron housing cast enbloc, whereas smaller sizes use die-cast aluminium housings. The worm shaft is manufactured from casehardened and hardened alloy steel and ground-finished.

The worm wheel has a cast iron hub with cast bronze insert. Hollow result shaft is supplied as standard.

Broad range of possibilities:

second input, result flange, single or dual extension output shaft, torque limiter with through cable, torque arm.

Monthly Archives: February 2020

servo reducer

These provide torque multiplication and rate reduction for the operation of prime movers in commercial machinery. Some have integral motors while others are provided with adapters for motors to become added.

From simple movement to heavy duty applications, we have a speed reducer for you.

Whether your servo app is in industrial automation, robotics, CNC machinery or automated manufacturing, everything you really require is a sophisticated, high-quality servo motor with the capacity of top energy efficiency and reliable performance. Leading semiconductor solutions from Infineon’s vast portfolio let you own it all: quality, intelligence, efficiency – and the purchase price you demand. Discover what your servo motor can achieve when you choose servo drivers, microcontrollers and more from Infineon. See additional engine control applications within industrial automation.

A servo electric motor is made from a compatible engine coupled to a sensor that provides feedback about the position. In addition, it necessitates having a refined controller specifically made for servo motor make use of. As a rotary actuator, it allows specific control of the position, velocity and acceleration. A distinctive characteristic of the servo motor can be that it consumes power while rotating to the required position and then rests upon arrival.

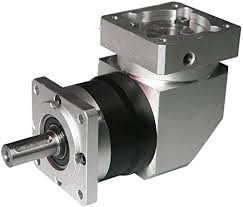

Servo-Worm Reducers were particularly developed for make use of with the latest servo motors in applications that demand specific positioning and repeatability.

These reducers are ideal for applications in material handling, automation, machine tool, and robotics.

The light weight modular aluminum housing design allows for easy machine integration, and excellent heat dissipation. A multitude of insight flanges and couplings are available to permit easy mounting of nearly any servo-motor and custom flanges could be accommodated. Output configurations with pinion, hollow bore, or solid shaft are available and will be configured for input with motor flange, free insight shaft, or both totally free input shaft and engine flange.

Our close partnerships with this installed customer foundation provided much insight into their evolving dependence on more high-precision right-angle gearing options.

These servo grade speed reducers are ideal for the most challenging of movement control applications. Each series incorporates a globoidal worm equipment mesh design in order to accomplish the torque handling capability and the highest levels of precision our customers have come to anticipate from us. The  insight design of our EJ right-angle gearbox applies the same idea of motor modularity that is common across our High Precision item family, meaning our clients and distribution partners get the same level of flexibility, product range, and overall availability that is unparalleled in your industry.

insight design of our EJ right-angle gearbox applies the same idea of motor modularity that is common across our High Precision item family, meaning our clients and distribution partners get the same level of flexibility, product range, and overall availability that is unparalleled in your industry.

This standard range of Servo Reducers are ideal for use in applications that demand high performance, precise positioning and repeatability. These were specifically developed for use with state-of-the-art servo engine technology, providing tight integration of the motor to the unit. Angular backlash of less than 1 arc-mins is provided standard.

To view comparable servo reducer products we provide click here.

greenhouse gear reducer

Our columns are constructed of 2” diameter PVC pipe. A bell-shaped reducer fitting guaranteed to underneath of the pipe stabilizes the column, and also holds in place a mesh screen. The mesh facilitates the Turface substrate while also permitting drinking water to drain by gravity. An automated watering program delivers a dilute nutrient solution to each column. The watering system is programmed to add small amounts of nutrient option at the substrate surface 20 times per day. This high frequency maintains the tops of the columns moist and ensures delivery of nutrition throughout the column.

We have developed a columnar plant lifestyle system that facilitates healthy plant growth while also enabling complete separation of the roots from the development substrate.

Standard potting substrates typically contain sphagnum peat blended with perlite or vermiculite. These well-drained, organic-rich mixtures support an appropriate balance of water and oxygen while also providing exchange surfaces for plant nutrients. Separation of plant roots from the potting substrate, however, is impossible.

An oil expansion chamber controls the pressure in the drive unit and further escalates the reliability of the machine. Consequently, the drive device can be used atlanta divorce attorneys placement. We has been examined under severe conditions with high operating cycle and positive results have been achieved.

The new type of greenhouse reducer is a window in the greenhouse, universal screen reducer, it uses aluminum die-cast housing, beautiful appearance, light weight (about 20 kg), good temperature dissipation, output torque (400N.m  ~ 800N. m), low noise characteristics. It adopts bottom level mounting and side mounting, which facilitates installation and decreases the labor strength of the installation employees.

~ 800N. m), low noise characteristics. It adopts bottom level mounting and side mounting, which facilitates installation and decreases the labor strength of the installation employees.

reducer in addition to light-weight, high strength light weight aluminum alloy shell, the internal utilization of a three-stage helical gear transmission, thin oil lubrication. Increased transmission efficiency and service existence. Its limit device offers two types of collision block and spring sheet for customers to choose. The limit adjustment is usually practical, and the positioning accuracy is high (specifically the spring type). Could be adjusted within the range of 1~75 rpm to control the stop between the negative and positive of the electric motor. There is absolutely no double insurance change to make sure safe operation.

1. The cabinet framework is solid, reasonable, reliable performance, simple procedure and maintenance

2. The limiting device has the best wiring method, through three micro-switches, each of which features as a brake, emergency brake, and phase mistake protection

Columnar containers are better pots because they are able to support deep root growth while taking up less bench space. Many columns can be arranged within a small area, like a gas-exchange chamber, therefore maximizing the number of remedies and replications in confirmed space.

What could Greenhouse Gear Reducer provide for you? You ask We inform.

servo worm reducer

These provide torque multiplication and acceleration reduction for the operation of prime movers in industrial machinery. Some have essential motors while others are provided with adapters for motors to end up being added.

From simple movement to heavy duty applications, we’ve a velocity reducer for you.

Whether your servo app is in industrial automation, robotics, CNC machinery or automated manufacturing, everything you really need is a sophisticated, high-quality servo motor capable of top energy efficiency and  reliable performance. Leading semiconductor solutions from Infineon’s vast portfolio let you have it all: quality, cleverness, efficiency – and the price you demand. Uncover what your servo electric motor can achieve when you select servo drivers, microcontrollers and more from Infineon. See additional motor control applications here in industrial automation.

reliable performance. Leading semiconductor solutions from Infineon’s vast portfolio let you have it all: quality, cleverness, efficiency – and the price you demand. Uncover what your servo electric motor can achieve when you select servo drivers, microcontrollers and more from Infineon. See additional motor control applications here in industrial automation.

A servo electric motor is constructed of a compatible electric motor coupled to a sensor that gives feedback about the position. Furthermore, it necessitates having a refined controller particularly designed for servo motor make use of. As a rotary actuator, it enables specific control of the positioning, velocity and acceleration. A unique feature of the servo engine is definitely that it consumes power while rotating to the required position and then rests upon arrival.

Servo-Worm Reducers were specifically developed for use with the most recent servo motors in applications that demand precise positioning and repeatability.

These reducers are suitable for applications in material handling, automation, machine tool, and robotics.

The light-weight modular aluminum housing design permits easy machine integration, and excellent heat dissipation. A wide variety of insight flanges and couplings are available to allow easy mounting of almost any servo-motor and custom flanges can be accommodated. Result configurations with pinion, hollow bore, or solid shaft are available and may be configured for insight with motor flange, totally free input shaft, or both totally free input shaft and engine flange.

Our close partnerships with our installed customer foundation provided much insight into their evolving need for more high-precision right-angle gearing options.

These servo grade speed reducers are perfect for the most challenging of movement control applications. Each series incorporates a globoidal worm gear mesh design to be able to accomplish the torque handling capability and the highest levels of precision our clients have come to expect from us. The insight design of our EJ right-angle gearbox applies the same idea of motor modularity that’s common across our High Precision product family, meaning our customers and distribution companions get the same level of flexibility, product range, and overall availability that is unparalleled within our industry.

This standard range of Servo Reducers are ideal for use in applications that demand powerful, precise positioning and repeatability. These were specifically developed for make use of with state-of-the-art servo motor technology, providing tight integration of the motor to the machine. Angular backlash of significantly less than 1 arc-a few minutes is provided standard.

They can be purchased in four sizes (50 mm to 100 mm center range) with input speeds up to 5,000 rpm, reduction ratios from 4.75 to 52:1 and output torque capacities up to 1700Nm. A wide variety of engine couplings and mounting flanges are available for assembly to virtually all servo motors, and the hollow bore result can be utilized to mount result shafts, pinion shafts, or other drive elements.

Regular applications for these reducers include precision rotary axis drives, traveling gantries & columns, material handling axis drives, zero-backlash axis drives and electronic line shafting. Industries served include Material Handling, Automation, Aerospace, Machine Tool and Robotics.

Our selection of worm gearboxes is specially suited to demanding stepper and servo electric motor applications.

The range covers:

torque rankings up to 4700Nm continuous

torque ratings up to 7800Nm peak (12,800Nm maximum emergency end torque)

input speed 6000 maximum

backlash right down to 0.5 arc-min

solid, hollow and robot flange result shaft options

We test the stator windings, replace bearings, repair the armature, convert and undercut the commutator, rewind the motor, dip and bake the windings and fully test all of the electro-mechanical properties of your servo motor.

Our electronic restoration laboratory performs repairs at component level (tachometer, encoder, resolver, hall effects or tachsyns). Feedback devices are modified to the correct timing, waveform form, offset angle, and voltage level.

Our in-home machine shop can restoration or remanufacture damaged shafts, sleeve endbells, or repair electric motor housings. Shafts are dynamically balanced to mil specifications to eliminate vibration.

State-of-the-art equipment enables us to precisely set encoder or feedback alignment and to run test the electric motor.

Designers generally convert to gear reducers in servopositioning applications for two reasons. 1st, many applications require much less swiftness and more torque than economically available from a servo-motor alone. A equipment reducer trades top-end speed, which may not be required, for higher result torque. Servomotors typically run at 3,000 to 5,000 rpm although for small, high-power applications, some motors are wound to use at higher speeds.

Second, a servocontrolled program has optimized performance when load inertia and electric motor inertia are comparable. Settling-time delays frequently result if load inertia is certainly high compared with motor-armature inertia. Equipment reducers solve this universal problem, reducing reflected inertia (the load inertia noticed by the control program) by the sq . of the gear reduction ratio. For instance, a 5:1 reduction ratio provides a 25:1 reduction in the reflected load-inertia ratio, ensuring stable program operation and optimal machine performance.

When high performance is necessary, one good option is integral planetary gears, where the gear set is portion of the actuator unit. In various other systems gears bolt to the electric motor and are not always planetary. A servoactuator gives among the highest power densities available in an electric-actuator program and is useful in applications that want high torque and/or power while reducing weight and space. Common uses include robotics, materials managing, packaging machinery, and process control.

Planetary gearheads have high torque rankings because several gears uniformly share the strain. The mixing motion of the planet gears with the external ring gear keeps all the teeth well lubricated. A single drop of oil on one tooth evenly redistributes over the entire gear set, which is not the case for nonplanetary equipment reducers. Planetary reducers also offer low backlash, which may be important for positioning accuracy and servosystem stability.

A planetary-geared servoactuator offers all the benefits of standard servomotors and bolt-upon planetary gear-heads with several drawbacks. Add-on servogearheads make use of a collar clamp to attach the pinion gear and motor shaft, which causes problems for some users. The pinion equipment may mount too much in or out and reduce the mesh with additional gears. It can be misaligned, which decreases gear-head life. And incorrect fastener torque can lead to failure under load. Geared servomotors without clamps eliminate these problems and boost the system stiffness. Integrated planetary-geared actuators may also reduce inertia by eliminating unneeded components. This can improve performance through lower RMS current and quicker environment times.

Fewer components also offer compact packaging compared to bolt-on reducers. Bolt-on gear-heads regularly use right-angle gears to reduce the length a reducer extends beyond a machine. Right-angle gears, however, require yet another set of bevel gears to help make the convert. These gears increase the solution’s size, price, complexity, and total backlash since another mechanism is placed between your load and the motor. Usage of beveled gears defeats the advantage of a planetary gearhead altogether.

Some planetary-geared servo-motors offer additional options. For instance, oil-circulation lubrication and cooling lets devices operate consistently at up to three times the nominal torque and power ranking. Oil-cooling also helps to keep the actuator great in high-temperature environments. Other options include explosionproof designs, alternative materials and coatings, customized shafts, nonstandard electric motor voltages such as for example 24 or 48 Vdc, special feedback devices, and special electrical connectors to use with most amplifiers.

This standard selection of Precision Planetary Reducers are perfect for use in applications that demand powerful, precise positioning and repeatability. They were specifically developed for make use of with state-of-the-art servo electric motor technology, providing limited integration of the engine to the unit. Style features include mounting any servo motors (IEC, NEMA, or personalized motors), standard low backlash, high torsional stiffness, 95 to 97% efficiency and silent running.

They are available in nine sizes with decrease ratios from 3:1 to 600:1 and output torque capacities up to 16,227 lb.ft. The output can be provided with a solid shaft or ISO 9409-1 flange, for installation to rotary or indexing tables, pinion gears, pulleys or other drive components without the need for a coupling. For high precision applications, backlash amounts down to 1 arc-minute are available. Right-angle and insight shaft versions of these reducers are also obtainable.

Regular applications for these reducers include precision rotary axis drives, traveling gantries & columns, material handling axis drives and electronic line shafting. Industries offered include Material Managing, Automation, Aerospace, Machine Tool and Robotics.

The servo gearboxes PT complete the whole selection of our servo gearboxes that consist of high-end planetary gearboxes, right angle gearboxes, hypoid gearboxes, cycloid gearboxes as well as various combinations thereof. All common servo motors could be easily installed with all sizes of our gearboxes. Our PT servo planetary gearboxes assure high stiffness and reliable transmission through their particular design. All ring gears, planet gears and sunlight pinions are case – hardened and ground. This provides a superb transmission quality and allows for precise positioning tasks.

Please call us if you need to find out more regarding servo worm reducer.

worm gear speed reducer

Solitary reduction worm gearing offers high ratio reduction with few moving parts in a close-coupled compact drive. The right angle arrangement of driving-to-driven machine requires a minimum of space. Input and result shafts can be extended in either or both directions in horizontal or vertical arrangements adaptable to any mounting requirement. Efficient engine speeds are reduced to sluggish speed requirements of several industrial machines in one reduction.

Product Features

Ratios 5:1 to 70:1

Hollow & Solid Output Shafts

Vertical & Horizontal Mounting

Fan Cooled (Standard)

Motor Mounts (C-Encounter Adapters or Scoops)

Cast Iron or Metal Housings

Products

The exclusive use of the involute Helicoid Thread form (with leaving side contact) on the worm and gear offers high efficiencies, and long service existence. The hardened floor and polished alloy metal worm develops a easy, work hardened surface on the bronze gear. Because of this worm gears put on in and improve with extented service while various other gears are wearing out. EP offers a wide selection of model configurations, sizes, ratios, and accessories from our standard product line.

Fabricated Designs

If the application involves severe shock loads or possible housing damage from external sources (as in steel mills or mobile gear applications) EP can offer fabricated steel housings with up to 48″ center distances. Fabricated housings provide maximum rigidity and strength which allows the transmitting of higher horsepower amounts than are feasible with regular cast iron models. Extra heavy part plates connect the worm and equipment shaft bearing facilitates, assuring correct meshing of the gear under all load conditions. In smaller sized sizes, fabricated metal reducers are interchangeable with EP regular cast iron reducers.

Custom Designs

EP can offer custom quickness and reversed engineered reducers for your application, be it a fresh project or a primary drop-in alternative to a competitor’s swiftness reducer. Fabricated metal reducers enable EP to match a competitor’s footprint, centerline, and shaft height allowing a primary drop-in replacement saving the customer time and money.

Long – Quiet Life

All worm gears in EP reducers are manufactured from phosphorous bronze. Our style also includes a hardened, surface and polished alloy metal worm. This combination develops a clean, work-hardened mating surface of the bronze equipment which boosts with prolonged service.

Worm gearing is a course of gear reducers that utilizes correct angle, nonintersecting shafts. This form of reducer provides even and quiet procedure and permits the likelihood of large velocity reductions. These gears are available from share in a wide selection of ratios, from as low as 4:1 up to 3600:1. The compact design and structure allows worm gear reducers to be positioned in a relatively small space. Thus, high reductions in a restricted package size may be accomplished with this configuration. Our worm equipment features the constant sliding tooth action between worm and one’s teeth. This increases the tolerance for heavy loads and shock loads. Worm gear drives offer users high reducing capacity for relatively low cost in comparison with various other types of gearing.

The use of worm gearing extends across many industries including food, beverage and grain and has many applications. Some applications that utilize worm gearing are: conveyors, mixers and bucket elevators.

EP worm gear reducer gearbox series bottom on years of encounters uses designed teeth surface with unsurpassed torque transfer performance with great functionality, efficency and price.Worm gear system transmits power through sliding contact, resulting in extremely low vibration , sound, small backlash and self-locking property

-Housing:Onetime we casting creats great rigidity for serious impacts. Outer cooling fins and inner lubrication essential oil diversion channel style to improve heat dissipation.

-Worm  Shaft: Manufactured with Carbon alloyed Steel S45C or SCM415, precison machined and carburized to HRC45 or HRC60, after that for precision tooth grinding to make sure maximum contacting.

Shaft: Manufactured with Carbon alloyed Steel S45C or SCM415, precison machined and carburized to HRC45 or HRC60, after that for precision tooth grinding to make sure maximum contacting.

-Worm Wheel: Manufactured with Carbon alloy ALBC2, teeth are machined by precision CNC hobbing machine to sustain high impact.

A worm equipment reducer is one kind of reduction gear container which includes a worm pinion input, an output worm equipment, and features a right angle output orientation. This kind of reduction gear container is generally used to have a rated motor swiftness and create a low speed output with higher torque worth based on the decrease ratio. They often times can resolve space-saving problems because the worm gear reducer is among the sleekest reduction gearboxes available due to the small diameter of its result gear.

worm gear reducerWorm equipment reducers are also a popular type of quickness reducer because they provide the greatest speed decrease in the smallest package. With a higher ratio of speed reduction and high torque output multiplier, it’s unsurprising that many power transmission systems make use of a worm gear reducer. Some of the most typical applications for worm gears are available in tuning instruments, medical examining equipment, elevators, security gates, and conveyor belts.

SW-1 and SW-5

Torque Transmission offers two sizes of worm equipment reducer, the SW-1 and the SW-5 and both are available in a variety of ratios. The SW-1 ratios include 3.5:1 to 60:1 and the SW-5 ratios include 5:1 to 100:1. Both of these options are produced with rugged compression-molded glass-fill polyester housings for a long lasting, long lasting, light-weight speed reducer that’s also compact, non-corrosive, and nonmetallic.

Features

Our worm gear reducers offer an option of a solid or hollow output shaft and show an adjustable mounting placement. Both SW-1 and the SW-5, however, can endure shock loading much better than other reduction gearbox designs, making them ideal for demanding applications.

Rugged compression-molded glass-fill up polyester housing

Light weight and compact

Non corrosive

Non metallic

Range of ratios

SW-1, 3.5:1 to 60:1

SW-5, 5:1 to 100:1

Grease Lubrication

Solid or Hollow output shaft

Adjustable mounting position

Worm Gear Reducers also called worm gearbox or worm velocity reducers. Worm gear reducers are utilized for speed reduction and increasing the torque for electric motor drives. You can choose to mount your NEMA motor to the reducer utilizing the NEMA C encounter flange or use a coupling. If you want a coupling for the result or input shaft see our coupling section for choosing the coupling. We offer four assemblies left hands and right hands and double output shaft and shaft input and shaft output. Interchangeable with most worm gear manufactures. Observe data sheet in product overview for diamensions. Unless you see your type, please Contact Us.

8 Ratios Available from 5:1 to 60:1

7 Gear Box Sizes from 1.33 to 3.25″

Universally Interchangeable Style for OEM Replacement

Double Bearings Applied to Both Shaft Ends

Anti-Rust Primer Applied Outside and inside Gearbox

Shaft Sleeve Protects All Shafts

S45C Carbon Metal Shafts

Flange Mount Versions for 56C and 145TC Motors

EP DDVM series triple-reduction worm gear velocity reducers can be found in ratios from 5000:1 to 175,000:1 and middle distances from 7” to 20” (larger sizes on request). Output torque ranges from 33,000 in pounds. for the 7” CD DDVM-70 to 582,900 in pounds for the DDVM-200. Mechanical HP insight requirements are from 0.09 HP for the 175,000:1 7 in CD reducer to 6.25 HP for the 5000:1 20” CD unit. These reducers are available in four configurations: horizontal, vertical, shafted, and shaft installed.

These reducers are well suited for water/waste-water devices drive applications such as for example thickeners and clarifiers, which require a vertical down shaft. Other obtainable configurations also make EP triple reduction reducers perfect for use on mixers, elevators, solar panels, astronomical telescopes, indexing tables, hoists, conveyors, or other process or materials handling systems where huge torques/slow speeds are needed.

These reducers are also available with a helical main reduction stage and are termed the HDVM series

Product Features

Ratios 5000:1 to 175,000:1

HP from 0.09 to 6.25.

Output Torque to 583,000 in lbs.

Output RPM as low as 0.01 with a 1750 RPM input.

Ideal for ultra-slow velocity, high torque applications

8 Ratios Available from 5:1 to 60:1

7 Gear Box Sizes from 1.33 to 3.25″

Universally Interchangeable Style for OEM Replacement

Double Bearings Used on Both Shaft Ends

Anti-Rust Primer Applied Outside and inside Gearbox

Shaft Sleeve Protects All Shafts

S45C Carbon Metal Shafts

Flange Mount Models for 56C and 145TC Motors

Description

The HDR Series worm gear reducers are found in low to moderate horsepower applications to reduce speeds and increase torque. Worm gear reducers are available in direct or indirect drive, direct drive versions are 56C or 145TC flange install with either right, left or dual output shafts or a hollow bore output. The indirect drive versions are shaft input-shaft output boxes for make use of with sprocket or pulley drive systems. They offer an effective low cost solution to speed reduction and increased torque, with higher tolerances for shock loading than helical gear reducers.

In order to select a gearbox speed reducer, you will have to determine the required torque and services factor for the application. Click on “Specifications” above for a desk that will assist in determining the service aspect. For service elements above 1.0, multiply the mandatory torque by the provider factor.

Our standard 700 Series – the heart of EP acceleration reducer products – has been serving industry reliably for over 40 years. Its verified modular style has set the market standard for overall performance and may be the most imitated item in the current worm gear quickness reducer marketplace. But why settle for a knock-off when you’re able to have the initial – from EP.

Specifications

11 basic one reduction sizes

8 basic dual reduction sizes

1/6 – 25 HP

5:1 – 100:1 ratios single reduction

100:1 – 3600:1 ratios double reduction

Non-flanged, NEMA C-face quill, and coupled input styles

Projecting and hollow result shafts

Projecting diameters from 1/2″ to 2-1/4″

Hollow result bore diameters from 5/8″ to 3-7/16″ (with over 20 bore sizes in stock)

Product Features

The 700 Series’ large oil reservoir provides efficient heat dissipation and lubrication for longer operating existence.

Its multi-position mounting flexibility allows for installation in virtually any position.

Housings are straddle-milled, best and bottom level, for precise alignment of horizontal and vertical bases.

Internal baffles assure positive, leak-free venting.

The 700 Series’ rugged casing, fabricated of fine-grained, gear-quality cast iron, provides optimum strength for maximum durability, and also greater precision during worm and gear alignment.

EP 700 Series high-strength bronze worm gear is straddle mounted between heavy-duty tapered roller bearings to improve thrust and overhung load capacities, sizes 713-760.

Our 700 Series’ high-strength steel result shaft assures convenience of high torque and overhung loads.

Pipe plugs allow easy fill, level, and drain in virtually any mounting position.

The 700 Series’ super-finished oil-seal diameters on both input and output shafts extend seal existence.

Both 2D and 3D CAD drawings can be found in our eCatalog.

TheIncreased Quality! Industrial Ranked! Inexpensive!One-piece gearcase, without exterior ribs, is constructed of close-grained cast iron and provides for rigid gear and bearing support. In addition, it offers excellent high temperature dissipation.Double lip, spring-loaded seals protect from oil leakage and prevent dirt from entering.Stepped shafts with oversized ball andtapered roller bearings.Carbon metal shafts for greater strength.High tensile strength cast bronze worm wheel and hardened and floor alloy steel worm made intregal with the shaft for long and trouble-free life.Essential oil sight gauge for simple maintenance (unavailable upon sizes 25 and 34).Factory oil stuffed.Every unit test run just before shipment.Universal mounting with bolt-on feet.Highly modifiable design.All this at substantially reduce prices than you have already been accustomed to spending money on reducers of lesser quality. Less

Do you would like to know more regarding worm gear speed reducer?

servo gear reducer

WORM SERVO GEAR REDUCER

Features

Wide variety of servo gearboxes, made to fit virtually all servo motors found on the market

Designed for the best torsional stiffness and the cheapest angular backlash, designed for the maximum torque and overhung loads

Bush with slot machine games and hub clamp for servomotor coupling

Benefits

Enhanced dimensional compactness because of direct servomotor coupling

Widest range of feasible servomotors coupling dimensions.

The correct technical solution because of a comprehensive range of sizes, gear stages, transmission ratios, designs and nonstandard designs.

Catalogs:

Servo equipment reducers (worm, coaxial, helical and bevel helical devices) Catalog SR

Operating instructions:

Operating instructions for equipment reducers and gearmotors (UTD.045)

EP Drive Systems, Inc. is very happy to announce the growth of our range of Servo Reducers, at this point offering five degrees of precision to meet up any application requirements. The five degrees of precision obtainable allows a machine developer to select the required reducer precision to meet their needs and their spending budget. They can be purchased in both in-series and right-angle versions, in torques up to 7,376 lb.ft. and ratios to 3,392:1.

Standard applications for these reducers include rotary & linear axis drives, and materials handling axis drives. Industries offered include Material Managing, Automation, Aerospace, Machine Tool and Robotics.

The mounting faces of the HT, HP, Electronic and B versions are identical, which makes it possible to interchange a unit with a higher or lower accuracy unit if needed.

A wide range of engine couplings and installation flanges are available for the entire reducer range to mount virtually any servo motor and the hollow bore output can be used to mount output shafts, pinion shafts, or other drive components.

These reducers are usually selected predicated on the peak cycle forces, which usually happen during accelerations and decelerations. These routine forces rely on the driven load, the speed vs. time profile for the routine, and any other external forces functioning on the axis. For more selection info, please follow this PDF link.

For application & selection assistance, please call, fax or email us. The application information will be reviewed by our engineers, who’ll recommend the best solution for your application.

EP Inc. provides a full selection of modular servo gearboxes /worm reducers. The modular design permits configurations with motor insight flange and output pinion for rack and pinion drives, along with solid result shafts, Hollow bore output, and insight shafts for all other positioning applications. The modular style allows for universal installation of the gearbox in any orientation.

They can be utilized on motors with a NEMA23 standard flange through an adaptor kit. As the gears are naturally angled, they result in a short total amount of the motor and its gear.

The series may also be delivered both right- and left-angled and with output shafts on both sides. A 30-mm machine recess for centering and a 4 M5 threaded mounting hole can also be built on the gear’s output side.

Built with a straightforward and robust style, the series has gearing ratios that range between 6:1 to 75:1. The user may also customize the materials through the order, in order to match the apparatus to its intended program.

The Precision Planetary Gears of the EPRG series contains a comprehensive selection of low backlash planetary gearboxes, with up to class 3′ precision, obtainable in several gear frame sizes, with single or multiple stage reduction (for gear ratios from 1:3 to at least one 1:1,000). These models likewise incorporate versions with double shaft, right angle shaft and right angle output, as well as a full range of adapters for electric motor mounting, making them capable of meeting the requirements of also the most diverse applications. They are designed for use with built-in servo and stepper EP motors, mounted directly or via adaptor flanges, but can also be used in combination with other EP motor types. This selection of products is founded on years of experience and represents the end result of a decade-long analysis aimed at improving performance.

Maximum precision and dynamics, coupled with excellent torque density, are the key requirements specified for reliable servo gearboxes used. EP provides servo gearboxes for any program and any functionality range. Our low-backlash planetary and right-angle gearboxes reflect our interest for development and the best levels of precision.

Worm gear reducers provide market progress solution with efficiency and flexibility. Low quantity of basic models can be applied to a wide selection of power ratings guaranteeing top performance and decrease ratios from 5 to 1000.

Gear reducers and servo gearboxes of EP Precision Machinery  Co., Ltd. are created for high-performance mechanical devices. When the motor swiftness must be reduced, the result torque raises and send torque totally to the application form. We believe that clients will appreciate our equipment reducer to accomplish their demand. Just visit EP, you can obtain more information regarding servo gearheads, servo gearboxes, and equipment reducers. We continue to keep in the years ahead for your support.

Co., Ltd. are created for high-performance mechanical devices. When the motor swiftness must be reduced, the result torque raises and send torque totally to the application form. We believe that clients will appreciate our equipment reducer to accomplish their demand. Just visit EP, you can obtain more information regarding servo gearheads, servo gearboxes, and equipment reducers. We continue to keep in the years ahead for your support.

Plug the Speed Reducer in to the desired channel of your receiver, and connect the lead from your servo (or servo wye) into the man servo lead coming from the circuit table. The arranged screw on the blue trim pot, located close to the top of the main circuit board, is utilized to control the acceleration of the servo. Change the set screw completely clockwise (CW) for normal servo speed without speed reduction, fully counter-clockwise (CCW) for optimum speed reduction, or any place in between for partial acceleration reduction. The reddish LED indicates three feasible conditions: Slower Blinking = No Signal; Solid On = No Swiftness Decrease; Fast Blinking = Reduced Acceleration Setting

Please note that if you make any change to the speed setting as the receiver is on, you need to cycle power to the receiver (convert if off and back on) for the brand new speed setting to take impact. This circuit may also be utilized in conjunction with this Servo Reverser to cause flap or retract servos to carefully turn in opposing directions for correct function. Guidelines are included for easy installation and use.

IMPORTANT NOTE: This device will only work on a regular, proportional servo. You won’t focus on a retract-type servo, as they do not recognize any servo positions other than clockwise (CW) and counter-clockwise (CCW). Retract servos can’t be slowed down, even by a transmitter which includes this function, as their design and electronics don’t allow it. Verify the FAQ page for more information.

This device will reduce the speed of any regular, proportional servo. Connect it between your receiver and the servo (or servos) you intend to control for a far more scale-like motion of flaps or retracts. Adjustable, it could be set to lessen the acceleration of your servo from super-slow motion to no speed decrease at all, with an almost infinite amount of positions in between. Maximum reduction period for a servo to visit 90 degrees is approximately 14 seconds, minimum period (no reduction) is simply the normal swiftness of the servo. Great for reducing or getting rid of the inclination of a plane to “balloon up” when flaps are deployed. It can be utilized to control more than one servo by usage of a normal servo Y.

This is actually the new regulated version that can be used on radio systems powered by any size or kind of battery, including 4.8-6.0 volt 4-5 cell Ni-Cad/Ni-MH electric batteries, and HV (high voltage) receivers that are powered by 2-cell 6.6-8.4 volt Li-Po/Li-Ion/Existence batteries. This unit won’t reduce the voltage going to your servos.

The EP Gear Reducer may be the perfect solution for servomotor applications such as for example packaging machines, gantries, injection molding devices, pick and place, and linear slides.Provided in concentric shaft, correct angle solid shaft, and correct angle hollow shaft styles with modular adaptor flanges and keyless compressible bushings to quickly mount to any manufacturer’s servo electric motor. The EP Series helical gears possess slanted teeth in comparison to spur gears with straight cut teeth, generating a smoother gear mesh, yielding considerably lower noise levels.

The reduced backlash EP planetary servo gear units are made for the 30 to 350 Nm (265 to 3100 lb-in) torque classes. They were designed to combine the greatest possible versatility and cost-efficiency because don’t assume all application requires high-performance parts.

They provide a basis for diverse, dynamic and cost-optimized drive solutions.

The EP planetary servo equipment units can be found in the following versions:

PSC = B5 output, easy output shaft

PSKC = B5 result, with keyway

PSCZ = B14, result, smooth output shaft

PSKCZ = B14 output, with keyway

Like what you found out? Share what you find out about servo gear reducer with your pals and family members by taking them to our website.

inline planetary gear reducer

In-Line Gearboxes | Inline Planetary Gearbox

Ever-Power offers regular and customized in-line gearboxes to meet the needs of nearly any motion or power transfer program. Our inline gearboxes are engineered for low backlash efficiency. They are precision built to provide reliable support in even the most demanding operations.

Read “10 Points to Consider to obtain the Gearbox You Need” for assistance in finding the best & most effective gear reducer option for your application. “Inertia and the usage of Inertia Figures” has an example and a formula for coping with inertia in gearbox selection.

Custom Inline Gearbox Solutions

All the inline gear drive models below could be customized to match your performance and app requirements. Demand a quote on a customized gearbox or contact Ever-Power to discuss your unique needs.

High Speed In-Line Spur Gear Box

In-Line Spur

High Performance, Low Backlash Rate Reducer Gearbox

Encoder, Low Backlash

In-Line Low Backlash Taper

In-Line Low Backlash Taper

Servo Gearbox | Planetary Gearbox | Servo Gear Reducer

Epicyclic Servo / Planetary

Inline Planetary Equipment Reducer Options

Gearboxes are known by many different names, including equipment drives, reducers, equipment reducers, swiftness reducers, and gearmotors. All conditions can be used more or less interchangeably when refering to inline planetary gear reducers.

Spur In-Line Gearboxes

Ever-Power offers a complete line of compact, light-weight spur equipment inline planetary gear reducers. These inline gearboxes can be immediate installed to motors or used with shaft coupling. Ratios from 2:1 to 625:1 can be found, with torque values which range from 0.13Nm to 90Nm.

Input quickness: up to 4,000 RPM

Precision machined aluminum housing

Dual ball bearings upon all shafts

Encoder Low Backlash In-Line Gearboxes

These compact, lightweight, low backlash gear drives are designed specifically for encoder applications. They have a very low second of inertia at the shaft input, and are rated for input boosts to 3,000 RPM. Gear ratios from 4.96:1 to 3600:1 are available, in two frame sizes. Synchro cleats for our encoder gearboxes are available from stock.

Output torque: 1 oz.-inch

Backlash: 15 arc-minutes (at any ratio)

Ratios from 4.96:1 to 3600:1

Input boosts to 3,000 RPM

Diameter: 1-1/16” or 1-3/4”

Black anodized aluminum housing

303 stainless steel gears and shafts

Ball bearings

Low Backlash Inline Taper Gearboxes

Our taper gearmotors are inline planetary equipment reducer boxes with backlash equal to or much better than 8 arc/minute. These inline gearboxes are made for applications where space is limited, and are obtainable either as a shaft insight or mounted to a 24V DC motor.

Low backlash: ≤8 arc/min. at input

Compact design

Shaft input or with mounted motor

Ratios from 2:1 to 16:1

Output torque ideals from 1.14Nm to 12.7Nm

Epicyclic (Planetary) Servo Gearboxes

The Ever-Power type of internal epicyclic servo reducers are extremely rugged and compact. These planetary gearboxes possess fully-machined housings (aluminum or steel), and are outfitted with ball bearings throughout. Our inline planetary equipment reducers offer flexible electric motor mounting options and will deliver output torques up to 380 Nm. Ratios from 3:1 to 36:1 are available.

Low backlash: ≤30 arc/min. at input

Input speeds because high as 3,000 RPM

Precision machined aluminum housings

Dual ball bearings on all shafts

Available in ratios from 3:1 to 36:1

Output torques since high as 380Nm

Speed Increaser Gearboxes

Our low ratio Encoder gearboxes and inline taper gearboxes can also be used as gear rate increasers, if needed.

The Ever-Power Advantage: 19 years of Unparalleled Quality

Greased for life

Input speeds since high as 4,000 RPM

Available with equipment ratios up to 3600:1

Customized gearboxes available

Fully machined from block housings

Ball bearings upon all shafts

Ever-Power offers a broad collection of misalignment shaft couplings in ” and metric bore sizes. Inch and metric Precision Ground Shafts can be found from stock.

Contact Us for High Performance Inline Gear Drives

Demand a quote on a custom made inline gearbox for your application. Contact Ever-Power to discuss your custom requirements.

Correct angle gearboxes (worm and planetary) are tough and built for 90° turns. Inline reducers (parallel shaft and planetary) are a perfect match for motors with high insight speeds, or when gearmotor efficiency is important. Contact our technical sales personnel for help identifying which gearbox option is most beneficial for you.

RIGHT ANGLE REDUCERS

WORM GEAR REDUCER

Groschopp’s worm equipment reducers were created with a hollow bore and allow for a corner change with optional dual result. The reducers come in 12 ratios ranging from 5:1 to 100:1, with non-back-drivable ratios 30:1 and higher. Our right angle gearboxes were created with five mounting choices providing  versatility when incorporating the reducer into item.

versatility when incorporating the reducer into item.

RIGHT ANGLE BEVEL GEARBOX

bevel-right-angle-gearbox

The right angle bevel gearbox combines the features of our right angle worm and planetary inline reducers. With a good and efficient correct angle configuration, our correct angle planetary gearboxes offer a robust solution. The proper angle bevel gearbox will come in 18 ratios which range from 5:1 to 1000:1, in fact it is back-drivable at all ratios.

INLINE REDUCERS

I-SERIES PLANETARY GEARBOX

i-series-planetary-gearbox

Our I-Series little planetary gearbox configurations supply the smallest footprint and quietest operation of our rate reducers. These gearboxes are created to handle varying loads with little backlash. With body sizes 52cm, 62cm, and 81cm, 12 ratios ranging from 5:1 to 308:1, we’ve a solution to fit your needs. Our 52 frame size can be available with plastic gears for noise-delicate applications.

INLINE PLANETARY GEARBOX

inline-planetary-gearbox

Our inline planetary gearbox configurations supply the highest performance and best output torque of most our speed reducers. These gearboxes are created to handle varying loads with little backlash. Planetary gear reducers operate more quietly than parallel shaft reducers. With 18 ratio options which range from 5:1 to 1000:1, we’ve a solution to fit your needs.

PARALLEL SHAFT GEARBOX

parallel-shaft-gearbox

Parallel shaft gearboxes are the top choice for constant duty applications. Their equipment cluster design provides an effective method for dissipating heat. Parallel shaft gearboxes possess the shortest amount of our inline gear reducer options therefore they work well in conditions with limited space. Our parallel shaft equipment reducers offer an affordable drop-in substitute solution for most little parallel shaft gearmotors.

The typical precision PE-series inline planetary gearheads can be found in 40-155mm frame sizes and provide high torque, low backlash, high input speeds and a small package size with a great price/performance ratio.

The PE-series planetary gearbox may be the perfect economy gearbox for all applications where considerably low backlash isn’t of vital importance.

Markets:

Factory Automation

Packaging Machinery

Food & Beverage

Miscellaneous Industrial

Miscellaneous Manufacturing

Lab/Diagnostic

Life Sciences

Pharma

Features/Benefits:

Frame Sizes: 40 – 155mm

Ratio Options: 3:1 – 64:1

Backlash: to < 7 arc-minutes

Efficiency: up to 97%

Quiet Operation: significantly less than 70db

High Insight Speeds: up to 18 000 RPM

Excellent price/performance ratio

High output torques

High quality (ISO 9001)

Any fitting position possible

Simple motor fitting

Life time lubrication

Direction of rotation equidirectional

Balanced motor pinion

Applications:

Industrial Equipments

In-Plant / Automotive Industry Equipments

Robotics

Special Machines

There are three main elements in a planetary gearbox: the sun gear, the planet gears and the ring gear. The gears are mounted on the planet carrier which has teeth on the inside, which may be the ring gear.

Planetary Reducer & Gearmotor

Planetary Gearbox – DieQua Corporation

Planetary gearboxes can easily produce many different reduction ratios because of the different planet gears that revolve around sunlight gear. Planetary gearboxes are made of heavy duty metallic such as for example steel and are able to handle large shock loads well. Nevertheless, different planetary gearboxes are designed for specific acceleration, load and torque capacities. The predominant use for planetary gearboxes is definitely in automobiles with automatic transmissions. Unlike manual transmitting, where the operator is accountable for switching gears, automobiles that have automatic transmissions use clutches, brake bands and planetary gearboxes to change the inputs and outputs, thereby adjusting the speeds accordingly.

An automatic tranny contains two complete planetary gearsets placed together into one element. Planetary gearboxes are also found in electrical screwdrivers, sprinklers and applications that require large or multiple reductions from a concise mechanism. Planetary gearboxes are among the many variations of velocity reducers in fact it is important that the right mechanism can be used. Gearboxes could even be combined to create the desired results and the most common kinds are helical gear reducers, worm gear reducers and inline gear reducers.

Planetary gearboxes gain their advantages through their design. Sunlight gear’s central placement allows the earth gears to rotate in the same path and for the ring gear (the advantage of the planet carrier) to turn the same way as the sun gear. In a few arrangements the sun gear can simultaneously switch all the planets as they also engage the ring gear. Any of the three components may be the input, the output or held stationary, which results in many different reduction ratio options.

In many planetary gearboxes one component is held stationary with another element serving as the input and the other as output. The decrease ratios for planetary gearboxes are dependent upon the number of tooth in the gears and what elements are engaged. Generally, the strain ability and torque increases with the amount of planets in the machine because the load is definitely distributed among the gears and there is usually low energy waste; planetary gearboxes are highly efficient, averaging between 96 and 98%. The design is complex, however, and difficult to gain access to for repairs or maintenance.

Axial or Inline gearboxes refer to this kind of types as Helical, Shaft mounted, or planetary styles.

These gearboxes are extremely common selections for most industrial applications due to their robust nature, high permissible radial forces, closely stepped ratios and low backlash.

Helical gearboxes can typically be within applications requiring high permissible radial force, stepped ratios and low backlash.

Shaft-mounted or otherwise referred to as Parallel shaft gearboxes offer an inline option with a versatile and space saving foot print. This is the only inline gearbox edition with the choice of a hollow output shaft.

Planetary gearboxes are often chosen for hi-tech, high torque, high speed applications requiring severe accuracy.

Learn everything you have actually ever before needed to know concerning Inline Planetary Gear Reducer.

helical speed reducer

“EP series” inline helical equipment reducers feature a HP range of ¼-100 HP, 37-147 mm box sizes, 2:1-120:1 speed ratios and a cast iron housing for unquestioned strength and reliability. Offered in a number of NEMA  C-encounter quill style motor input flange configurations, the “EP” series allows users to easily locate off-the-shelf NEMA motors in lieu of custom equipment motors with special initial pinion gears. EP’s bolt hole pattern, foundation to center line height, output shaft diameter and usable shaft length match the “R” series of the inline market leader producing plant retrofitting a breeze.

C-encounter quill style motor input flange configurations, the “EP” series allows users to easily locate off-the-shelf NEMA motors in lieu of custom equipment motors with special initial pinion gears. EP’s bolt hole pattern, foundation to center line height, output shaft diameter and usable shaft length match the “R” series of the inline market leader producing plant retrofitting a breeze.

Product Features

2:1 – 120:1 ratios (other ratios offered as custom orders)

Box sizes 37 – 147

Built for high efficiency, high strength, and low noise

All cast iron housings for unquestioned strength and reliability

Wide variety of ratios from 2:1 to 120:1

Horsepower range between 1/4 HP to 100 HP

Gears are precision ground for better rotation and quieter operation

Gearbox flanges are designed to accept NEMA C-Face electric motors

Drop-in for some major European-produced Inline reducer brands

2-year warranty

The precision planetary gear units of the EP series with surface helical gearing and preloaded dual taper roller bearings guarantee low-noise synchronism due to their immense load having capacity and rigidity even under high load conditions. The one-piece planet carrier and the included needle roller bearings enable the tranny of high torques. The additional shaft sealing ring ensures maximum security against dirt and splash water in accordance with protection class IP65.

Design

The selection of a proper planetary gear for your

individual application.

Short delivery time

Small quantities on short notice. Delivery

time for larger quantities or special requests needs to be

checked individually

CAD drawings

Drawings for all series are available on request

Flexibility

For personalized solutions we draw from a large range of

single components. Depending on demand they may be

combined for you in a flexible way

EP isn’t only known for its comprehensive manufacturing

expertise. Our customers also revere us as skilled partners in

drive technology. This experience is the basis of our planetary gear

series.

We place great importance on your own versatility in the configuration and

app of our planetary gears. Being faithful to our motto customer

satisfaction is always a priority.

Quality

Our top quality standards apply to every our planetary gearbox series.

Included in these are especially high gearing quality, low backlash and long

service life.

Innovation

Fast response to customer requests and constant additional development of our planetary gears is definitely our driving force.

Close grained cast iron casing and flanges

Hardened steel helical gearing for extended life

Anti-friction bearings

Double lip seals protect from oil leakage

Optional steel bolt-on base

Double bearing design on input and output shaft

EP Gear’s 800 Series contains a focused collection of compact, heavy duty helical gear drives that offer long-life performance and simplified maintenance. A broad range of reduction ratios fit an even broader selection of specifications, while a variety of insight shaft configurations maximize flexibility. In addition, the number of products that complement this series of gear drives make it a perfect choice for today’s industrial distributor.

The 800 Series offers a functional interchange for ep and other European producers’ helical gear drives,making it uniquely practical for replacement applications.

Four basic sizes 1/6 – 10 HP

Over 40 different ratios 1.5:1 – 71:1 double-reduction ratios 36:1 – 250:1 triple-reduction ratios

Non-flanged and NEMA c-face input styles

Base-mount and result flange-mount models available

Output-shaft diameters from 3/4″ to 1 1 5/8″

The standard NEMA C-face design encourage any standard NEMA electric motor, making it exceptionally versatile.

Ratios up to 70:1 in just two stages means increased performance and reduced case size.

Accessible oil seals simplify regimen product maintenance.

All units can be double sealed on both the input and output to withstand the rigors of even the most demanding applications.

800 Series drives come pre-filled with synthetic lubrication for your specific mounting position.

Sizes 3 and 4 are lubricated forever which promotes trouble-free operation.

Washdown duty models in white or stainless epoxy coatings make these equipment drives well suited for the most severe Washdown.

Correct angle bevel speed reducers decrease speed and increase torque from the driver end to the driven result in a drive system. They have got a beveled gear that allows the reducer to rotate in both directions and operate with low noise and vibration. They are typically crafted from durable, corrosion-resistant components like stainless steel.

Features

Wide range of accessories and non-standard designs

Single piece housing with high structural stiffness

Benefits

Easy and functional shaft-mounting design

Minimum maintenance requirements

High, reliable and tested performance

Ideal for the heaviest duties

This economical aluminum body helical speed reducer provides highly reliable power transmission for general purpose applications. These gearboxes offer cost effective operation and superior overall performance over similar products.

5 sizes with aluminum housings

Torque capacity from 200-6000 inlbs

Ratios from 2.5:1 to 600:1

Output shafts in ” or metric dimensions

Input adapters for NEMA and IEC motors

Mounting via foot, face or bolt-on flange

The exclusive usage of the involute helicoid thread form on the worm and gear provides for high efficiencies and lengthy service lifestyle on draglines and shovels. The hardened,floor and polished alloy metal worm develops a clean, work hardened surface on the bronze gear. For this reason, the worm gears wear in and improve with prolonged service while additional gears are deteriorating.

Hardened, shaved or surface helical gears

Hollow & solid output shafts

Vertical & horizontal mountings

Fan cooled (standard)

Motor mounts

Cast iron or steel housings available

small planetary gearbox

Standard ratios from 4:1 to 36:1

Additional ratios available upon request

Attractive pricing for cost-sensitive applications

Increased Torque Output at an Attractive Price

Little step motors and integrated motors are popular in applications where space is at reduced, but these little motors don’t always produce enough torque for challenging applications. EP Mini Planetary Gearheads are the perfect solution, offering increased torque and better inertia coordinating without breaking the spending budget.

All steel gear teach and output shaft

Input boosts to 6,000 rpm

Minimal backlash

All Metal Construction for Durability and Performance

Each EP Mini Gearhead features an all-steel equipment train, stainless steel casing, and aluminum front and back flanges for optimum durability. Each element of the gearbox is  usually precision machined to exacting tolerances before getting assembled into the final reducer. The result is usually a gearhead that may accept input boosts to 6,000 rpm and offer high output torques with minimal backlash.

usually precision machined to exacting tolerances before getting assembled into the final reducer. The result is usually a gearhead that may accept input boosts to 6,000 rpm and offer high output torques with minimal backlash.

SMALL, COST EFFECTIVE PLANETARY GEARMOTORS

Small motors and built-in motors with pre-assembled planetary gearboxes

True planetary design

Precision cut gears

All metal construction for long life

High torque and precise positioning

Miniature design for use with small motors

Superb for increasing torque and inertia matching in a small size

Our small planetary gearbox are build to last, dependable and minimum mistake tolerance that’s suitable in aerospace, automation, smart household, electrical tools, medical gadgets and robotics applications.

stainless steel worm reducers

The brand new EVP37 and EVP37 stainless steel gearboxes from EP can be found with ratios up to 134.82 and 106.38:1 respectively. Both have an input power rating as high as 3 HP and an output torque ranking of 1 1,770 lb-in.

The EVP37 and EVP37 can be found with NEMA C-face electric motor adapters, IEC adapters or as gearmotors. Other choices include seals to supply IP69K protection and food grade essential oil. All shafts and hardware are high quality stainless steel as standard.

The shaft-mounted gear products can be found with EPLOC, EP’S small keyless hollow shaft mounting system. EPLOC combines interchangeable bronze bushings and a stainless steel clamping ring for mounting onto numerous sized solid shafts. This eliminates the need for high tolerance machining of the shaft and guarantees the reducer could be easily removed also after years of assistance in the harshest environments.

Traditional single-worm reducers commonly found on processing equipment are inefficient and wear as time passes. Helical bevel gears possess an infinite life, and are 50% more efficient than single worm gears. The brand new stainless steel acceleration reducers are new externally, but inside you will discover the same high-quality gearing the sector offers relied on for decades.

Lyman, SC – EP announces the immediate release  of the new EVP37 stainless steel helical gear reducer and EVP37 stainless helical bevel equipment reducer. Efficient, long-lifestyle helical and helical bevel gearing means these models use less energy, run cooler and last longer than usual single-worm gear devices. The material, design and smooth finish imply high resistance to bacteria, chemicals and procedures common to the meals processing industry.

of the new EVP37 stainless steel helical gear reducer and EVP37 stainless helical bevel equipment reducer. Efficient, long-lifestyle helical and helical bevel gearing means these models use less energy, run cooler and last longer than usual single-worm gear devices. The material, design and smooth finish imply high resistance to bacteria, chemicals and procedures common to the meals processing industry.

To watch similar stainless steel worm reducers items we provide click on this link.