The former area describes that by combining with many attachments, the DK Conveyor Chains can be used for pretty much all common applications. This part describes the DK Specialty Conveyor Chains produced based on the Conventional Conveyor Chain. Specialty Conveyor Chains provide improved kind, size series and material advantages that suit respective applications. They can be classified into 3 sorts: Specialized Application Conveyor Chain, Water Treatment Conveyor Chain, and 3D Bending Conveyor Chain.

Conveyor Chain with Attachments for Conveying Bulk Resources

Constant Flow Conveyor Chain and Chain for Dust Conveyor

A chain with blades is operated within a powder to cause the powder to movement from the exact same direction as the feeding course from the chain. This really is named a Continuous Movement Conveyor Chain. Precisely the same form of chain can be utilized in a similar way for discharging the dust produced by a variety of dust collectors. We manufacture 25 forms of Conventional Conveyor Chains with blades, two styles of Block Chains with blades , respectively appropriate to the various properties of dusts and powders, and five chains with distinctive cast steel blades for conveying powders more likely to lead to wear. The respective chains are designated as follows:

We manufacture continuous flow conveyors and  dust conveyors utilizing the above chains with blades as standard products. Consult us for even more facts.

dust conveyors utilizing the above chains with blades as standard products. Consult us for even more facts.

(a) Constant Flow Conveyor Chain

Continuous Flow Conveyor Chains are utilized for our typical constant movement conveyors. Based on the conveyed subjects, the following 3 kinds of attachments are available. The fundamental chain is often either a Normal Conveyor Chain or a Solid H-type Conveyor Chain.

(b) Chains for Dust Conveyor

This chain is employed for conveyors solely for carrying dust. Based on the application, the following 3 kinds are available:

1) Roller S Conveyor Chain for lower density powder with Attachment B or B1 for U and LU Type Dust Conveyors

2) Roller M Conveyor Chain for medium density powder with Attachment KL or KUL for DU, DU-S, LDU and LDU-S Kind Dust Conveyors

three) Block Chain for hugely abrasive powder with KL or KUL attachments for DUB, DUB-S LDUB and LDUB-S Style Dust Conveyors

Monthly Archives: January 2021

You will discover several different variety for heat therapy and specs to the conveyor chains. Distinct treatment options is usually utilized not only to the chain like a complete but to just about every part individually, this kind of as pins or plates only.

Select wanted combinations in reference on the following explanation of functions and utilizes.

Double Guard Coating

The surface is taken care of with outstanding corrosion resistant coating that approaches the resistance of stainless steel. Double guard coating consists of double layers of two distinctive supplies. It exhibits just about doubled corrosive resistance inside the salt water spray check in contrast to our traditional large guard coating, and might be utilized in mild alkaline or mild acidic ailments up to pH3.

With its enhanced corrosive resistance, it can be used in circumstances in which large guard or plated coatings can’t be utilized, as well as in some situations wherever only stainless steel could be used.

(Double guard coating cannot be utilized to welded parts.)

Higher Guard Coating

Large guard coated surface has excellent corrosion resistance.

The surface of the chain is completed in non-gloss white really protective coating. It’s excellent resistance to salt corrosion and rusting. This coating protects chains in large temperatures because it can resist heat as much as about 250°C.

Because substantial guard coating acts like a sacrificial anode for that chain entire body, you could assume adequate corrosion resistance even if the coating has come off to some extent. Also, it may be applied to welded parts.

It can be suggested for outdoor  use or close to the sea in circumstances exactly where effectiveness as substantial as that of stainless steel will not be required. In circumstances that need resistance to alkaline and acid, double guard or stainless steel coating is encouraged because they have greater resistance than substantial guard.

use or close to the sea in circumstances exactly where effectiveness as substantial as that of stainless steel will not be required. In circumstances that need resistance to alkaline and acid, double guard or stainless steel coating is encouraged because they have greater resistance than substantial guard.

Plating

Plating is primarily performed with nickel. It’s a coating with both interesting exterior and corrosion resistance. Through the use of it with grease lubrication, it exhibits superb corrosion resistance. You can count on the result to delay hydrogen brittle destruction when used in situations in which chains are exposed to sea breeze or acidic sprays.

(Double guard coating can’t be utilized to welded parts.)

You can find a variety of assortment for heat treatment method and specifications for your conveyor chains. Precise treatments is usually applied not merely for the chain as a whole but to every single component separately, such as pins or plates only.

Select wanted combinations in reference to your following explanation of options and employs.

Double Guard Coating

The surface is taken care of with excellent corrosion resistant coating that approaches the resistance of stainless steel. Double guard coating includes double layers of two unique supplies. It exhibits practically doubled corrosive resistance while in the salt water spray check in contrast to our typical substantial guard coating, and may be utilized in mild alkaline or mild acidic situations up to pH3.

With its enhanced corrosive resistance, it could possibly be used in conditions wherever high guard or plated coatings cannot be applied, and in many cases in some situations in which only stainless steel is usually used.

(Double  guard coating cannot be utilized to welded parts.)

guard coating cannot be utilized to welded parts.)

Substantial Guard Coating

Higher guard coated surface has exceptional corrosion resistance.

The surface from the chain is completed in non-gloss white really protective coating. It’s superb resistance to salt corrosion and rusting. This coating protects chains in substantial temperatures as it can resist heat as much as about 250°C.

Because higher guard coating acts as a sacrificial anode for your chain entire body, you can expect sufficient corrosion resistance even when the coating has come off to some extent. Also, it may possibly be utilized to welded parts.

It really is proposed for outdoor use or near the sea in situations in which performance as substantial as that of stainless steel is not really vital. In circumstances that demand resistance to alkaline and acid, double guard or stainless steel coating is proposed as they have much better resistance than substantial guard.

Plating

Plating is generally done with nickel. It is actually a coating with the two interesting exterior and corrosion resistance. By using it with grease lubrication, it exhibits fantastic corrosion resistance. You’ll be able to anticipate the effect to delay hydrogen brittle destruction when utilized in circumstances where chains are exposed to sea breeze or acidic sprays.

(Double guard coating can’t be applied to welded components.)

one.R-roller

R-roller Conveyor Chains have rollers with an outer diameter bigger than the width of plates.

Because the rollers can quickly roll, the chain is appropriate for operating on the floor though the rollers obtain the dwell load.

2.F-roller

F-roller Conveyor Chains have rollers using the similar outer diameter as that of R-roller but with flanges.

Since the flanges can receive the force acting on the lateral sides on the chain, the chain is appropriate for getting both a reside load plus a lateral load. three.M-roller

three.M-roller

M-roller Conveyor Chains have rollers with an outer diameter slightly smaller sized compared to the width of plates.

An M roller is built for smoother engagement with the sprockets. Since the chain is light in excess weight, it is actually ideal for vertical conveyance.

4.S-roller

S-roller Conveyor Chains have rollers with an outer diameter smaller than that from the M-roller.

The chain is ideal for vertical conveyance where rollers are much less more likely to be worn.

5.BR- and BF- Rollers (with built-in bearings)

BR- and BF- Roller Conveyor Chains have mostly identical framework to R-roller and F Conveyor Chains, respectively, except for your bearings within for smoother rotation.

six.UR- and UF- Rollers (massive clearance involving bushing and roller)

UR- and UF- Roller Conveyor Chains have largely identical structure to R-roller and F Conveyor Chains, respectively. Nonetheless, the clearances concerning the outer diameter of bushings and also the inner diameter from the rollers are enlarged to stop the rollers from repairing when foreign issues enter.

one.R-roller

R-roller Conveyor Chains have rollers with an outer diameter greater than the  width of plates.

width of plates.

Since the rollers can very easily roll, the chain is suitable for running around the floor even though the rollers receive the live load.

two.F-roller

F-roller Conveyor Chains have rollers together with the identical outer diameter as that of R-roller but with flanges.

Because the flanges can acquire the force acting within the lateral sides with the chain, the chain is appropriate for acquiring both a reside load along with a lateral load.

3.M-roller

M-roller Conveyor Chains have rollers with an outer diameter slightly smaller than the width of plates.

An M roller is intended for smoother engagement using the sprockets. Because the chain is light in fat, it can be ideal for vertical conveyance.

4.S-roller

S-roller Conveyor Chains have rollers with an outer diameter smaller than that with the M-roller.

The chain is ideal for vertical conveyance wherever rollers are much less more likely to be worn.

five.BR- and BF- Rollers (with built-in bearings)

BR- and BF- Roller Conveyor Chains have typically identical construction to R-roller and F Conveyor Chains, respectively, except to the bearings within for smoother rotation.

6.UR- and UF- Rollers (significant clearance amongst bushing and roller)

UR- and UF- Roller Conveyor Chains have largely identical construction to R-roller and F Conveyor Chains, respectively. Nonetheless, the clearances amongst the outer diameter of bushings and also the inner diameter of the rollers are enlarged to prevent the rollers from repairing when foreign matters enter.

DK Conveyor Chains are available within a wide range of dimensions, roller forms, and materials and heat remedy. On top of that, the chains is usually utilized for any broad range of application with our in depth selection of attachments and further capabilities.

Classified by Dimensions

DK Conveyor Chains is often classified into regular, powerful H-type and robust Z-type with reference to your dimension of the base chain.

The Normal Conveyor Chain is the basic type of DK Conveyor Chains, and lots of attachments, components, heat treatments, and so forth. can be found.

The Solid H-type Conveyor Chain was originally designed like a chain for bucket elevators with enhanced power and is now out there within a series. A small-sized Solid H-type Conveyor Chain is nearly equal in strength to a large-sized Conventional Conveyor Chain, but since the dimensions and kind differ, sprockets aren’t interchangeable. Generally, Solid H-type Conveyor Chains are greater in strength than Conventional Conveyor Chains with about the exact same roller diameter.

Strong Z-type Conveyor Chains are further enhanced in power than Robust H-type Conveyor Chains by elevating the height of the inner plates, as well as the sprockets are interchangeable if your nominal variety would be the similar. Sturdy H-type Conveyor Chains are utilized in machines by which the plates slide on the floor, such as constant flow conveyors, since the inner and outer plates possess the same height.

Alternatively, Sturdy Z-type Conveyor Chains exhibit large fatigue power and therefore are used in vertical conveyor bucket elevators.

Classified by Roller Variety

The rollers of the conveyor chain perform not simply to engage the sprockets moving the chain but in addition to rotate and travel on a rail, conveying content articles with small frictional loss. To meet several shapes of rails and protect against meandering, and so on., four kinds of rollers, big roller, flange roller, medium roller and little roller.

Moreover, for smoother rotation, we offer significant rollers and flange rollers with built-in bearings (BR and BF rollers, respectively), and UR and UF rollers with large clearances amongst the bushing as well as roller to avoid the entry of foreign matters into the bearings.  These rollers tend to be used in waste processing services.

These rollers tend to be used in waste processing services.

On this catalogue, substantial rollers, flange rollers, medium rollers and tiny rollers are respectively expressed as R-roller, F-roller, M-roller and Roller S.

DK Conveyor Chains can be found inside a range of dimensions, roller varieties, and material and heat remedy. Furthermore, the chains can be utilised for a broad assortment of application with our in depth choice of attachments and supplemental functions.

Classified by Dimensions

DK Conveyor Chains might be classified into normal, solid  H-type and sturdy Z-type with reference towards the dimension of the base chain.

H-type and sturdy Z-type with reference towards the dimension of the base chain.

The Conventional Conveyor Chain is definitely the basic type of DK Conveyor Chains, and lots of attachments, materials, heat solutions, etc. can be found.

The Robust H-type Conveyor Chain was initially developed like a chain for bucket elevators with enhanced strength and is now accessible in a series. A small-sized Sturdy H-type Conveyor Chain is nearly equal in power to a large-sized Conventional Conveyor Chain, but because the dimensions and type vary, sprockets are certainly not interchangeable. Usually, Robust H-type Conveyor Chains are greater in power than Conventional Conveyor Chains with with regards to the very same roller diameter.

Powerful Z-type Conveyor Chains are more enhanced in strength than Strong H-type Conveyor Chains by elevating the height with the inner plates, plus the sprockets are interchangeable when the nominal amount could be the same. Strong H-type Conveyor Chains are utilized in machines through which the plates slide within the floor, such as constant flow conveyors, since the inner and outer plates possess the exact same height.

On the flip side, Powerful Z-type Conveyor Chains exhibit large fatigue strength and therefore are utilized in vertical conveyor bucket elevators.

Classified by Roller Form

The rollers of a conveyor chain perform not just to engage the sprockets moving the chain but in addition to rotate and travel on a rail, conveying posts with little frictional loss. To meet several shapes of rails and prevent meandering, etc., four varieties of rollers, significant roller, flange roller, medium roller and smaller roller.

Moreover, for smoother rotation, we supply significant rollers and flange rollers with built-in bearings (BR and BF rollers, respectively), and UR and UF rollers with large clearances among the bushing along with the roller to stop the entry of foreign matters to the bearings. These rollers are sometimes utilized in waste processing facilities.

On this catalogue, significant rollers, flange rollers, medium rollers and compact rollers are respectively expressed as R-roller, F-roller, M-roller and Roller S.

Any time you layout numerous conveyor techniques applying little conveyor chains, the next standard circumstances needs to be satisfied.

a. Chain tension: The actual tensile strength in operation needs to be drastically decrease than the specified power with the chain.

b. Strength of loaded components of chain: The actual loads applied to attachments, this kind of as rollers of base chain, best rollers, side rollers, and so forth. in operation have to be considerably smaller sized than the strength of those components.

c. Wear lifestyle of chain: Lubrication problems to guarantee the wear daily life of chain have to be fulfilled.

d. Sag adjustment of chain: The sag from the chain have to be stored optimum by tension adjusters, take-up products, guides, etc.

e. Many others: Ideal measures are taken to stop rail dress in, machine vibration and other problems.

The following complement the above.

Calculation of Chain Tension

On the whole, to start with, tentatively determine the chain size to be applied referring to “Tentative determination of chain size”. Then, acquire “Theoretical chain stress (T)” (P213) for the tentatively established chain, and multiply the worth by “Speed coefficient (K)”, to obtain “Substantial chain tension (Ta)”. For safety, the considerable chain stress need to be decrease compared to the “maximum allowable tension” stated while in the table of dimensions of respective chains. Consequently, the problem beneath should be pleased.

Safety affliction of chain stress

Considerable chain stress (Ta) =Theoretical chain tension (T) ×Speed coefficient (K)

Considerable chain tension (Ta) <Maximum allowable stress

If this ailment will not be satisfied, decide on a bigger chain by one particular size and re-calculate.

Tentative determination of chain dimension

qDetermine the mass (fat) per unit length of elements such as chain and attachment ωc (kg/m or kgf/m) assuming that it is actually 10 percent with the mass (excess weight) with the conveyed object ω1 (kg/m or kgf/m).

wIn reference for the calculation formulas on, get “Theoretical chain tension (T)” (kN or kgf) and “Speed coefficient (K)”, and determine “Substantial chain stress (Ta)” (kN or kgf).

eIn reference on the table of dimensions of chains,identify the minimum chain, whose “maximum allowable tension” is greater  compared to the “Substantial chain tension (Ta)”, and regard it as “tentatively determined chain”.

compared to the “Substantial chain tension (Ta)”, and regard it as “tentatively determined chain”.

Value of pace coefficient (K)

The pace coefficient (K) expresses the severity of operation ailment according towards the traveling pace of chain because the issue becomes severer because the traveling velocity of chain gets to be larger.

Multiply “Theoretical chain stress (T)” by “Speed coefficient (K)” to obtain “Substantial chain stress (Ta)”.

If you layout numerous conveyor methods employing small conveyor chains, the following basic problems needs to be satisfied.

a. Chain stress: The real tensile power in operation must be significantly reduce than the specified strength in the chain.

b. Strength of loaded elements of chain: The real loads utilized to attachments, this kind of as rollers of base chain, best rollers, side rollers, and so on. in operation have to be significantly smaller sized than the power of these components.

c. Wear existence of chain: Lubrication ailments to be sure the wear life of chain must be fulfilled.

d. Sag adjustment of chain: The sag of the chain should be stored optimum by stress adjusters, take-up products, guides, and so on.

e. Others: Acceptable measures are taken to prevent rail wear, machine vibration as well as other problems.

The next complement the above.

Calculation of Chain Stress

On the whole, at the outset, tentatively identify the chain dimension to get utilized referring to “Tentative determination of chain size”. Then, acquire “Theoretical chain stress (T)” (P213) for the tentatively determined chain, and multiply the worth by “Speed coefficient (K)”, to obtain “Substantial chain stress (Ta)”. For safety, the significant chain tension have to be decrease compared to the “maximum allowable tension” stated in the table of dimensions of respective chains. Consequently, the affliction below need to be satisfied.

Safety condition of chain tension

Significant chain stress (Ta) =Theoretical chain tension (T) ×Speed coefficient (K)

Substantial chain tension (Ta) <Maximum allowable stress

If this  issue isn’t satisfied, decide on a bigger chain by 1 dimension and re-calculate.

issue isn’t satisfied, decide on a bigger chain by 1 dimension and re-calculate.

Tentative determination of chain size

qDetermine the mass (fat) per unit length of parts this kind of as chain and attachment ωc (kg/m or kgf/m) assuming that it can be ten percent with the mass (fat) from the conveyed object ω1 (kg/m or kgf/m).

wIn reference on the calculation formulas on, get “Theoretical chain tension (T)” (kN or kgf) and “Speed coefficient (K)”, and determine “Substantial chain stress (Ta)” (kN or kgf).

eIn reference on the table of dimensions of chains,identify the minimal chain, whose “maximum allowable tension” is greater than the “Substantial chain stress (Ta)”, and regard it as “tentatively made the decision chain”.

Value of velocity coefficient (K)

The velocity coefficient (K) expresses the severity of operation condition according to your traveling velocity of chain because the issue becomes severer because the traveling pace of chain becomes greater.

Multiply “Theoretical chain tension (T)” by “Speed coefficient (K)” to get “Substantial chain stress (Ta)”.

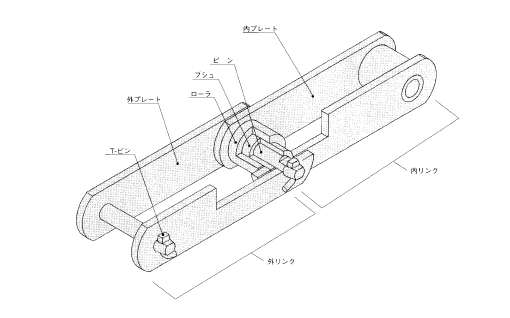

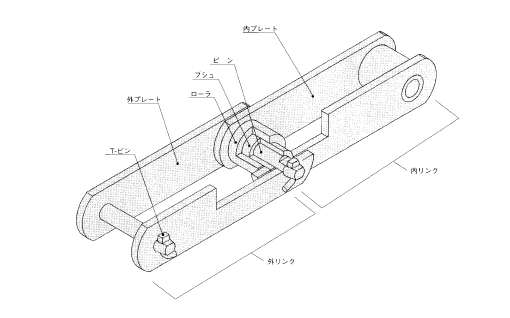

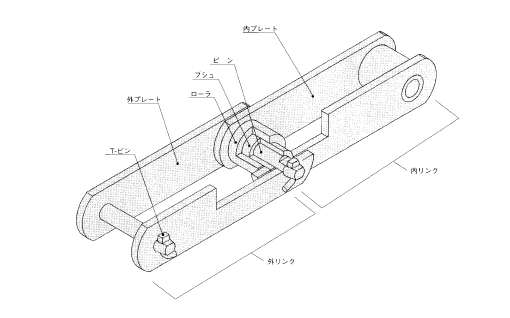

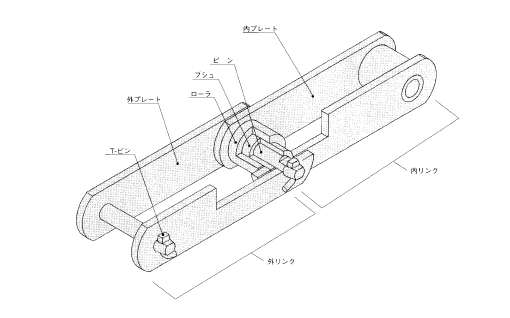

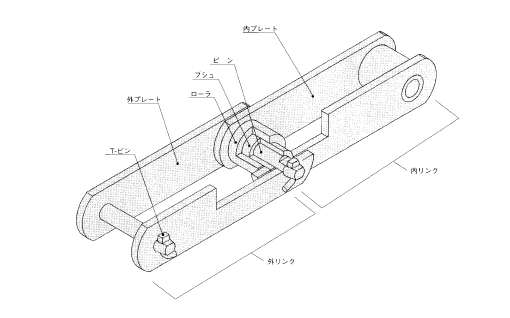

A DK conveyor chain has a construction, and also the names of your parts are stated from the drawing. These parts have functions specified under.

Pins

Pins assistance each of the load acting about the chain together with plates, and once the chain is engaged using the sprockets, they slide along with bushings as bearings. These are topic to put on and especially ought to have higher shear power, bending power and dress in resistance. Hardened and tempered tough steel, carburized steel, or induction-hardened steel is made use of.

Rollers

Rollers guard the chain from shocks together with the sprockets, and when the chain is engaged together with the sprockets, the rollers bend the chain smoothly and act to reduce the resistance once the chain runs on a rail. They are really needed to possess substantial shock fatigue strength, collapse power and put on resistance. Hardened and tempered hard steel, carburized steel or induction-hardened steel is used.

Bushings

Bushings are found involving pins and rollers and act as bearings for the two the pins and rollers not to  transmit the load acquired from the rollers right towards the pins when the chain is engaged using the sprockets. They can be essential to get higher shock fatigue strength, collapse power and dress in resistance, and on the whole, carburized steel is utilized.

transmit the load acquired from the rollers right towards the pins when the chain is engaged using the sprockets. They can be essential to get higher shock fatigue strength, collapse power and dress in resistance, and on the whole, carburized steel is utilized.

Plates

Plates are topic to repeated stress from the chain and often to massive shocks. They’re demanded to have high tensile strength, and especially substantial shock power and fatigue power. Higher tensile steel is applied for typical chains and heat-treated alloy steel for heavy-duty chains.

T-pins

T-pins prevent the outer plates from disengaging from the pins. They are manufactured from soft steel given that pins are commonly pressed-in the outer plates and as a result no big force acts over the T-pins.