Product Description

Gravity die-casting

Specification:

Gravity die casting

1. Open mould

2. Die casting

3. Casting (trim, grind, drill)

4. Surface treatment( anodize, chrome-plated)

Gravity die casting

Technological processed: Open mould— die casting —-casting (trim, grind, drill) —surface treatment

Gravity die casting detail:

1. Material: Aluminum (A380, A360, ADC12, ADC10) according to JISH5302: 2006 &ASTM

2. Process: Trim grind, drill, CNC

3. Surface treatment: Shot blashing, sandblasting or painting, anodize, electroplating, chrome-plated or all per customers’ requirement

Gravity die casting design & mold manufacture

2. Use the software: Auto CAD, RPO/Engineer, Solidwork, UG

3. Mold design

4. Trial the mold

5. Machine: EDM, CNC, Grinding Machine, Milling Machine, Tuning Machine, Wire Cutting Machine, Photo Engraving, Chemical Milling, Welder

| Item | description |

| type | Aluminum die casting Zinc die casting Magnesium die casting |

| manufature | HangZhouxinlong CZPT trade co., ltd |

| equipment | Cold chamber die casting machine |

| Machine capacity | 100T-800T |

| process | Tooling making: 20-30days tooling leadtime Casting: remove all burrs & sharp edges Machinng: CNC maching, milling, drilling, trimming, cutter, griding, wire cutter etc Surface treatment: shot blasting, sand blasting Polishing, powder coating, painting, , polishing, powder coating, chrome plating, nickel plating, passivating |

| Quality control | first checked after cast from die casting machine second checked by the warehouse people third checked after machining and surface finish. We check piece by piece each time |

| package | inner packing: PE bag or air bubble bag outer packing: double corrugated carton as per customers’ requirment |

| advantage | OEM service offered Send us you RFQ in details! We produce strictly according to customer’ s design and machining request. |

| Condition: | New |

|---|---|

| Certification: | CE, RoHS, GS, ISO9001 |

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Material: | Aluminum |

| Application: | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What Are the Advantages of a Splined Shaft?

If you are looking for the right splined shaft for your machine, you should know a few important things. First, what type of material should be used? Stainless steel is usually the most appropriate choice, because of its ability to offer low noise and fatigue failure. Secondly, it can be machined using a slotting or shaping machine. Lastly, it will ensure smooth motion. So, what are the advantages of a splined shaft?

Stainless steel is the best material for splined shafts

When choosing a splined shaft, you should consider its hardness, quality, and finish. Stainless steel has superior corrosion and wear resistance. Carbon steel is another good material for splined shafts. Carbon steel has a shallow carbon content (about 1.7%), which makes it more malleable and helps ensure smooth motion. But if you’re not willing to spend the money on stainless steel, consider other options.

There are two main types of splines: parallel splines and crowned splines. Involute splines have parallel grooves and allow linear and rotary motion. Helical splines have involute teeth and are oriented at an angle. This type allows for many teeth on the shaft and minimizes the stress concentration in the stationary joint.

Large evenly spaced splines are widely used in hydraulic systems, drivetrains, and machine tools. They are typically made from carbon steel (CR10) and stainless steel (AISI 304). This material is durable and meets the requirements of ISO 14-B, formerly DIN 5463-B. Splined shafts are typically made of stainless steel or C45 steel, though there are many other materials available.

Stainless steel is the best material for a splined shaft. This metal is also incredibly affordable. In most cases, stainless steel is the best choice for these shafts because it offers the best corrosion resistance. There are many different types of splined shafts, and each one is suited for a particular application. There are also many different types of stainless steel, so choose stainless steel if you want the best quality.

For those looking for high-quality splined shafts, CZPT Spline Shafts offer many benefits. They can reduce costs, improve positional accuracy, and reduce friction. With the CZPT TFE coating, splined shafts can reduce energy and heat buildup, and extend the life of your products. And, they’re easy to install – all you need to do is install them.

They provide low noise, low wear and fatigue failure

The splines in a splined shaft are composed of two main parts: the spline root fillet and the spline relief. The spline root fillet is the most critical part, because fatigue failure starts there and propagates to the relief. The spline relief is more susceptible to fatigue failure because of its involute tooth shape, which offers a lower stress to the shaft and has a smaller area of contact.

The fatigue life of splined shafts is determined by measuring the S-N curve. This is also known as the Wohler curve, and it is the relationship between stress amplitude and number of cycles. It depends on the material, geometry and way of loading. It can be obtained from a physical test on a uniform material specimen under a constant amplitude load. Approximations for low-alloy steel parts can be made using a lower-alloy steel material.

Splined shafts provide low noise, minimal wear and fatigue failure. However, some mechanical transmission elements need to be removed from the shaft during assembly and manufacturing processes. The shafts must still be capable of relative axial movement for functional purposes. As such, good spline joints are essential to high-quality torque transmission, minimal backlash, and low noise. The major failure modes of spline shafts include fretting corrosion, tooth breakage, and fatigue failure.

The outer disc carrier spline is susceptible to tensile stress and fatigue failure. High customer demands for low noise and low wear and fatigue failure makes splined shafts an excellent choice. A fractured spline gear coupling was received for analysis. It was installed near the top of a filter shaft and inserted into the gearbox motor. The service history was unknown. The fractured spline gear coupling had longitudinally cracked and arrested at the termination of the spline gear teeth. The spline gear teeth also exhibited wear and deformation.

A new spline coupling method detects fault propagation in hollow cylindrical splined shafts. A spline coupling is fabricated using an AE method with the spline section unrolled into a metal plate of the same thickness as the cylinder wall. In addition, the spline coupling is misaligned, which puts significant concentration on the spline teeth. This further accelerates the rate of fretting fatigue and wear.

A spline joint should be lubricated after 25 hours of operation. Frequent lubrication can increase maintenance costs and cause downtime. Moreover, the lubricant may retain abrasive particles at the interfaces. In some cases, lubricants can even cause misalignment, leading to premature failure. So, the lubrication of a spline coupling is vital in ensuring proper functioning of the shaft.

The design of a spline coupling can be optimized to enhance its wear resistance and reliability. Surface treatments, loads, and rotation affect the friction properties of a spline coupling. In addition, a finite element method was developed to predict wear of a floating spline coupling. This method is feasible and provides a reliable basis for predicting the wear and fatigue life of a spline coupling.

They can be machined using a slotting or shaping machine

Machines can be used to shape splined shafts in a variety of industries. They are useful in many applications, including gearboxes, braking systems, and axles. A slotted shaft can be manipulated in several ways, including hobbling, broaching, and slotting. In addition to shaping, splines are also useful in reducing bar diameter.

When using a slotting or shaping machine, the workpiece is held against a pedestal that has a uniform thickness. The machine is equipped with a stand column and limiting column (Figure 1), each positioned perpendicular to the upper surface of the pedestal. The limiting column axis is located on the same line as the stand column. During the slotting or shaping process, the tool is fed in and out until the desired space is achieved.

One process involves cutting splines into a shaft. Straddle milling, spline shaping, and spline cutting are two common processes used to create splined shafts. Straddle milling involves a fixed indexing fixture that holds the shaft steady, while rotating milling cutters cut the groove in the length of the shaft. Several passes are required to ensure uniformity throughout the spline.

Splines are a type of gear. The ridges or teeth on the drive shaft mesh with grooves in the mating piece. A splined shaft allows the transmission of torque to a mate piece while maximizing the power transfer. Splines are used in heavy vehicles, construction, agriculture, and massive earthmoving machinery. Splines are used in virtually every type of rotary motion, from axles to transmission systems. They also offer better fatigue life and reliability.

Slotting or shaping machines can also be used to shape splined shafts. Slotting machines are often used to machine splined shafts, because it is easier to make them with these machines. Using a slotting or shaping machine can result in splined shafts of different sizes. It is important to follow a set of spline standards to ensure your parts are manufactured to the highest standards.

A milling machine is another option for producing splined shafts. A spline shaft can be set up between two centers in an indexing fixture. Two side milling cutters are mounted on an arbor and a spacer and shims are inserted between them. The arbor and cutters are then mounted to a milling machine spindle. To make sure the cutters center themselves over the splined shaft, an adjustment must be made to the spindle of the machine.

The machining process is very different for internal and external splines. External splines can be broached, shaped, milled, or hobbed, while internal splines cannot. These machines use hard alloy, but they are not as good for internal splines. A machine with a slotting mechanism is necessary for these operations.

editor by CX 2023-07-13

China best 10W 12V24V90V DC Gear Motor With GearBox with Great quality

10W 12V/24V/90V DC Gear Motor With GearBox

Feature

1. CZPT Motor are made according to CE request

2. Excellent torque characterisitcs

3. Instantaneous start/stop

4. Reliable starting and directional stability

5. Virtually silent running for noise sensitive environments

6. Speed state invariable not effected by voltage under rated frequency

7. Winding will not ruin when motor over loading or abrupt stop running

8. High quality engineering ensures a quiet and long running life

Specification

ModelVoltage(v)Out put Power(w)No-load ParametersLoad ParametersBrush Life(H)Motor Weight(Kg)Speed(r/min)Current(A)Speed(r/min)Torque(mN.m)Current(A)Z2D10-12*121032001.0Max280034220000.7Z2DW10-12*121032001.0Max280034220000.7Z2D10-24*241033000.5Max3000320.920000.7Z2DW10-24*241033000.5Max3000320.920000.7Z2D10-90*957132000.3Max2800340.620000.7Z2DW10-90*957132000.3Max2800340.620000.7Dimension standard

Product show

All the materials of 10W 12V/24V/90V DC Gear Motor With GearBox is very good

Application

Other products

Packaging & Shipping Packing Method

1.Outer packing: Standard export carton with required shipping marks

2.Inner packing: Waterproof packing with shock absorbing EPE and cardboard surrounded

3.As per the clients requirements

Delivery & Shipment Method

We will ship the items after the payment.

We can ship to you by UPS/DHL/TNT/EMS/Fedex,by air and by sea.

For the Countries & Regions where EMS cannot deliver, Mini Drive Reduction Motor Reducer Case Hydraulic Parts Gear Gearbox pls choose other shipping ways;

Pls contact us directly and we will use your preferred ways

Our Services 1. Free maintenance within 12 months permanent.

2. Professional research and development team.

3. Technical support for installation.

4. Strict quality control system.

5. Customize production.

6. Competitive price.

Company Information CZPT Industries Development Co., Ltd. is a leading manufacturer for factory automation (FA) products ,we focus on power transmission and motion control solutions!

our main production are power transmission products like AC and DC(brush/brushless)gear motor, KBR-20136-00 Agriculture Drive Shaft PTO Shaft Triangular Pipe for tractor stepper motor,high precision planetary gearbox (spur/helical gear)for stepping motor etc

Welcome to visit our website to find more information http://lunyee.en.alibaba.com

FAQ Q1: How much does freight and what shipping method do you support?

A: Shipping is calculated based on the weight of the order and the distance it is travelling; we competitively price each order using our special shipping rates from our partners. For online shoppers you can see a shipping estimate after placing products in your shopping cart and starting to check out. Available online methods are EMS DHL FedEx TNT and so on.

Q2: When will my order be shipped?

A: All regular, sample orders shipped within 7 days after receiving your payment, Custom Orders have their own timeline depending on exactly what you need changed.

Q3: What is your After-Sale Service?

A: we supply free maintenance in warranty of 1 year

B: we supply free solutions during using.

Q4: I do not have the profession designer, Hot Selling Drive Shafts CV Joint Used for Nissan AEL-29178 would you provide the motor drawing?

A: Yes, we have the profession engineer in charge of the production design and research.

http://lunyee.en.alibaba.com

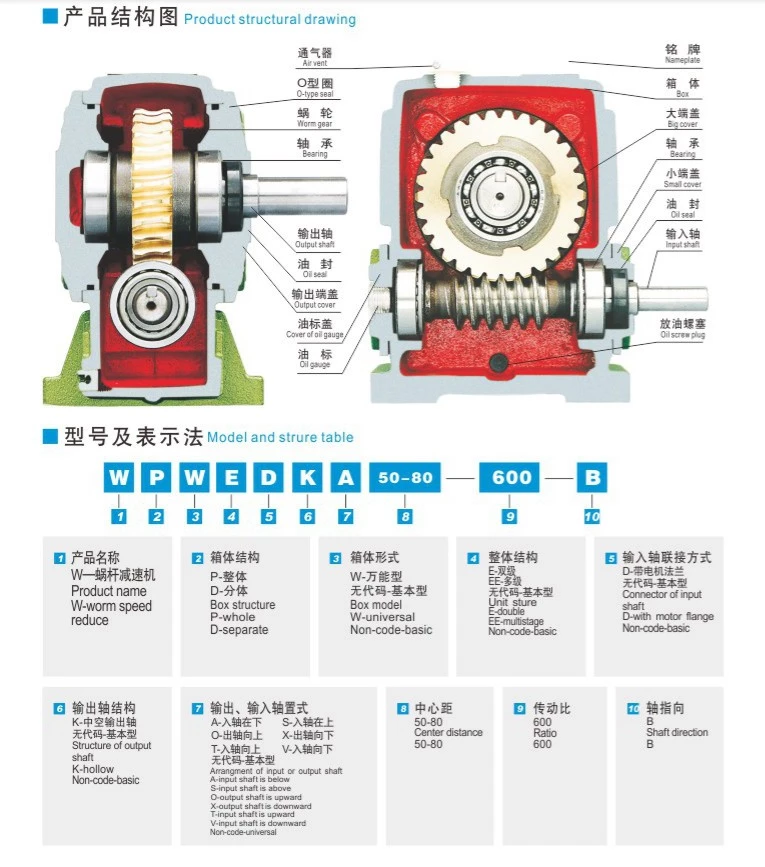

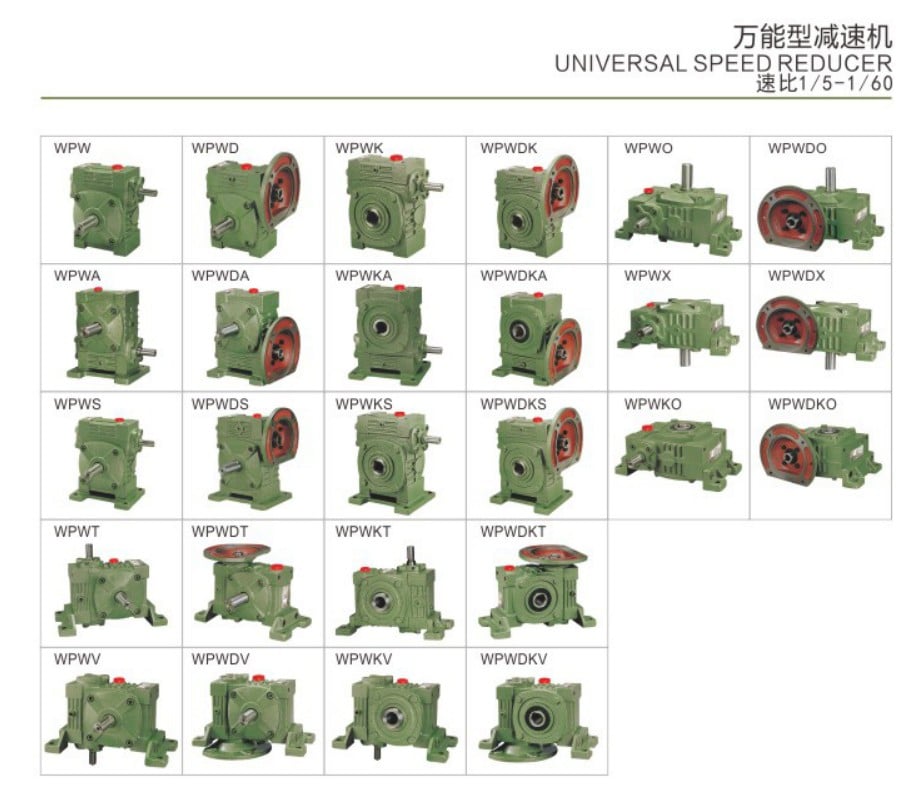

Worm Gear Motors

Worm gear motors are often preferred for quieter operation because of the smooth sliding motion of the worm shaft. Unlike gear motors with teeth, which may click as the worm turns, worm gear motors can be installed in a quiet area. In this article, we will talk about the CZPT whirling process and the various types of worms available. We’ll also discuss the benefits of worm gear motors and worm wheel.

worm gear

In the case of a worm gear, the axial pitch of the ring pinion of the corresponding revolving worm is equal to the circular pitch of the mating revolving pinion of the worm gear. A worm with one start is known as a worm with a lead. This leads to a smaller worm wheel. Worms can work in tight spaces because of their small profile.

Generally, a worm gear has high efficiency, but there are a few disadvantages. Worm gears are not recommended for high-heat applications because of their high level of rubbing. A full-fluid lubricant film and the low wear level of the gear reduce friction and wear. Worm gears also have a lower wear rate than a standard gear. The worm shaft and worm gear is also more efficient than a standard gear.

The worm gear shaft is cradled within a self-aligning bearing block that is attached to the gearbox casing. The eccentric housing has radial bearings on both ends, enabling it to engage with the worm gear wheel. The drive is transferred to the worm gear shaft through bevel gears 13A, one fixed at the ends of the worm gear shaft and the other in the center of the cross-shaft.

worm wheel

In a worm gearbox, the pinion or worm gear is centered between a geared cylinder and a worm shaft. The worm gear shaft is supported at either end by a radial thrust bearing. A gearbox’s cross-shaft is fixed to a suitable drive means and pivotally attached to the worm wheel. The input drive is transferred to the worm gear shaft 10 through bevel gears 13A, one of which is fixed to the end of the worm gear shaft and the other at the centre of the cross-shaft.

Worms and worm wheels are available in several materials. The worm wheel is made of bronze alloy, aluminum, or steel. Aluminum bronze worm wheels are a good choice for high-speed applications. Cast iron worm wheels are cheap and suitable for light loads. MC nylon worm wheels are highly wear-resistant and machinable. Aluminum bronze worm wheels are available and are good for applications with severe wear conditions.

When designing a worm wheel, it is vital to determine the correct lubricant for the worm shaft and a corresponding worm wheel. A suitable lubricant should have a kinematic viscosity of 300 mm2/s and be used for worm wheel sleeve bearings. The worm wheel and worm shaft should be properly lubricated to ensure their longevity.

Multi-start worms

A multi-start worm gear screw jack combines the benefits of multiple starts with linear output speeds. The multi-start worm shaft reduces the effects of single start worms and large ratio gears. Both types of worm gears have a reversible worm that can be reversed or stopped by hand, depending on the application. The worm gear’s self-locking ability depends on the lead angle, pressure angle, and friction coefficient.

A single-start worm has a single thread running the length of its shaft. The worm advances one tooth per revolution. A multi-start worm has multiple threads in each of its threads. The gear reduction on a multi-start worm is equal to the number of teeth on the gear minus the number of starts on the worm shaft. In general, a multi-start worm has two or three threads.

Worm gears can be quieter than other types of gears because the worm shaft glides rather than clicking. This makes them an excellent choice for applications where noise is a concern. Worm gears can be made of softer material, making them more noise-tolerant. In addition, they can withstand shock loads. Compared to gears with toothed teeth, worm gears have a lower noise and vibration rate.

CZPT whirling process

The CZPT whirling process for worm shafts raises the bar for precision gear machining in small to medium production volumes. The CZPT whirling process reduces thread rolling, increases worm quality, and offers reduced cycle times. The CZPT LWN-90 whirling machine features a steel bed, programmable force tailstock, and five-axis interpolation for increased accuracy and quality.

Its 4,000-rpm, 5-kW whirling spindle produces worms and various types of screws. Its outer diameters are up to 2.5 inches, while its length is up to 20 inches. Its dry-cutting process uses a vortex tube to deliver chilled compressed air to the cutting point. Oil is also added to the mixture. The worm shafts produced are free of undercuts, reducing the amount of machining required.

Induction hardening is a process that takes advantage of the whirling process. The induction hardening process utilizes alternating current (AC) to cause eddy currents in metallic objects. The higher the frequency, the higher the surface temperature. The electrical frequency is monitored through sensors to prevent overheating. Induction heating is programmable so that only certain parts of the worm shaft will harden.

Common tangent at an arbitrary point on both surfaces of the worm wheel

A worm gear consists of two helical segments with a helix angle equal to 90 degrees. This shape allows the worm to rotate with more than one tooth per rotation. A worm’s helix angle is usually close to 90 degrees and the body length is fairly long in the axial direction. A worm gear with a lead angle g has similar properties as a screw gear with a helix angle of 90 degrees.

The axial cross section of a worm gear is not conventionally trapezoidal. Instead, the linear part of the oblique side is replaced by cycloid curves. These curves have a common tangent near the pitch line. The worm wheel is then formed by gear cutting, resulting in a gear with two meshing surfaces. This worm gear can rotate at high speeds and still operate quietly.

A worm wheel with a cycloid pitch is a more efficient worm gear. It reduces friction between the worm and the gear, resulting in greater durability, improved operating efficiency, and reduced noise. This pitch line also helps the worm wheel engage more evenly and smoothly. Moreover, it prevents interference with their appearance. It also makes worm wheel and gear engagement smoother.

Calculation of worm shaft deflection

There are several methods for calculating worm shaft deflection, and each method has its own set of disadvantages. These commonly used methods provide good approximations but are inadequate for determining the actual worm shaft deflection. For example, these methods do not account for the geometric modifications to the worm, such as its helical winding of teeth. Furthermore, they overestimate the stiffening effect of the gearing. Hence, efficient thin worm shaft designs require other approaches.

Fortunately, several methods exist to determine the maximum worm shaft deflection. These methods use the finite element method, and include boundary conditions and parameter calculations. Here, we look at a couple of methods. The first method, DIN 3996, calculates the maximum worm shaft deflection based on the test results, while the second one, AGMA 6022, uses the root diameter of the worm as the equivalent bending diameter.

The second method focuses on the basic parameters of worm gearing. We’ll take a closer look at each. We’ll examine worm gearing teeth and the geometric factors that influence them. Commonly, the range of worm gearing teeth is one to four, but it can be as large as twelve. Choosing the teeth should depend on optimization requirements, including efficiency and weight. For example, if a worm gearing needs to be smaller than the previous model, then a small number of teeth will suffice.

Best near me shop made in China – replacement parts – PTO shaft manufacturer & factory Power how to remove pto shaft from gearbox Take off Gear Pump with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto manufacturing facility in China with 5 diverse branches. For a lot more particulars: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

pto connection types Principal rotavator pto shaft value merchandise rzr travel shaft contain: weasler travel shafts manure pto drive shaft types spreading 52123551aa truck, remove pto shaft from bush hog potato propeller shaft universal joints toyota tacoma planting/harvesting 2013 ram 2500 entrance drive shaft machine, generate shaft u joint orientation disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler devices, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its equipment: Plow disc blades, harrowing movie, plough idea and share, cultivator tine, casting areas and so on. EPG is prepared to cooperate sincerely and build commonly with pals! GRH specialized in providing hydraulic factors and remedies for hydraulic methods.

With constant improvement and enthusiasm over the p EPT thirty many years, EPT has designed into an emerging power in the fluid power industry since it was set up in 1986.

EPT (ZheJiang ) – EPT Income Business office

EPT (ZheJiang ) – Manufacturing Facility and Domestic Revenue Place of work

Creation description

| Model | displacement(ml/r) | pressure bar | pace rpm |

| peak | rated | ||

| CB-P160LJ53S33BB | one hundred sixty | 60(2250PSI) | a thousand |

| CB-P125LJ53S33BB | 125 | sixty(2250PSI) | one thousand |

| CB-P90LJ53S33BB | ninety | sixty(2250PSI) | a thousand |

| CB-P56LJ53S33BB | 56 | sixty(2250PSI) | a thousand |

| CB-P160LJ42H21SS | 160 | sixty(2250PSI) | 540 |

| CB-P125LJ42H21SS | a hundred twenty five | sixty(2250PSI) | 540 |

| CB-P90LJ42H21SS | 90 | sixty(2250PSI) | 540 |

About Us

Application and Associates

Make contact with us!

China manufacturer & factory supplier for china in Tangerang Indonesia supplier H B right angle helical bevel gear box 90 degree transmission gearbox type for sliding gate With high quality best price & service

The continued enlargement of our ball bearings, mounted units and power transmission solution traces, alongside with our consideration to depth and quality, has allowed EPG to acquire wide acceptance to a assorted client base.Our item variety also covers locking assemblies (clamping aspects/locking unit), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod finishes and yokes.

Overview

Quick Information

- Applicable Industries:

-

Producing Plant

- Rated Electrical power:

-

one.5~6229KW(personalized)

- Product Variety:

-

B3SH10

- Pole:

-

one stage two phase 3 phase

- Ratio:

-

two.8-2000

- Application:

-

for coal gold mining drilling products miner mine for sliding gate

- Content:

-

20CrMnTi Cast Iron Casing

- Working temperature:

-

-forty~45℃

- Sort:

-

B helical bevel equipment box ninety degree transmission gearbox kind

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

ninety two%~96%

Offer Ability

- Supply Capability:

- five hundred Established/Sets for each 12 months H B right angle helical bevel gear box 90 degree transmission ge

Packaging & Delivery

- Packaging Particulars

- sea deserving wooden scenario for H B right angle helical bevel equipment box 90 degree transmission gearbox kind for sliding gate

- Port

- Qingdao

On the web Customization

The PTO shaft is the mechanical gadget that transfer the power from the tractor to the agricultural apply. The PTO shaft is manufactured of two joints linked by telescopic tubes: one particular joint connects the outer tube of the PTO shaft with the tractor electricity consider-off , the other joint connects the interior tube of the PTO shaft with the implement. The variety of the EPG Group PTO shafts includes 9 dimensions of diverse proportions according to the energy to be transferred . The sizes of the EPG Group PTO shafts and the energy that can be transferred at 540 rpm are : Dimensions 1 up to 16HP Dimension 2 up to 21HP Dimensions 3 up to 30 HP Measurement 4 up to 35HP Size 5 up to 47HP Dimensions 6 up to 60HP Dimensions 7 up to 70HP Size 8 up to 90HP SIZE10 up to 110HP

Merchandise Description

YOUR Skilled MANUFACTURE

—— Since 1995

H B Series Industrial GearBox

At any time-Electrical power Machinery —— Tianqi Brand name

industrial gearbox manufacturers/Gear Box Transmission

Chinese electric motor velocity reducer is commonly used in mining equipment, chemical industry,steel metallurgy, light-weight industry,environmental safety, paper creating, printing, lifting transport, food market and so on.

Principal Series Product: R collection helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical equipment reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, and many others. In the meantime, map sample processing enterprise can be carried out.

Feature:

-

Recognized parallel shaft,appropriate-angle shaft modes and horizontal,vertical mounting modes. Using significantly less part components.

-

Making use of advanced grinding approach which enhanced the security and the effectiveness of transmit electrical power with lower noise.

-

Input method: motor related flange, shaft enter

-

Output mode:strong shaft with flat crucial,hollow shaft with flat key,hollow shaft with shrink disk,hollow shaft with spline connection, strong shaft with spline relationship, strong shaft with flange.

-

Mounting mode:vertical, horizontal, swing foundation-mounted, torque-arm-mounted.

-

Ratio range:1.23~450. It can be increased when combining with K&R sequence reducer.

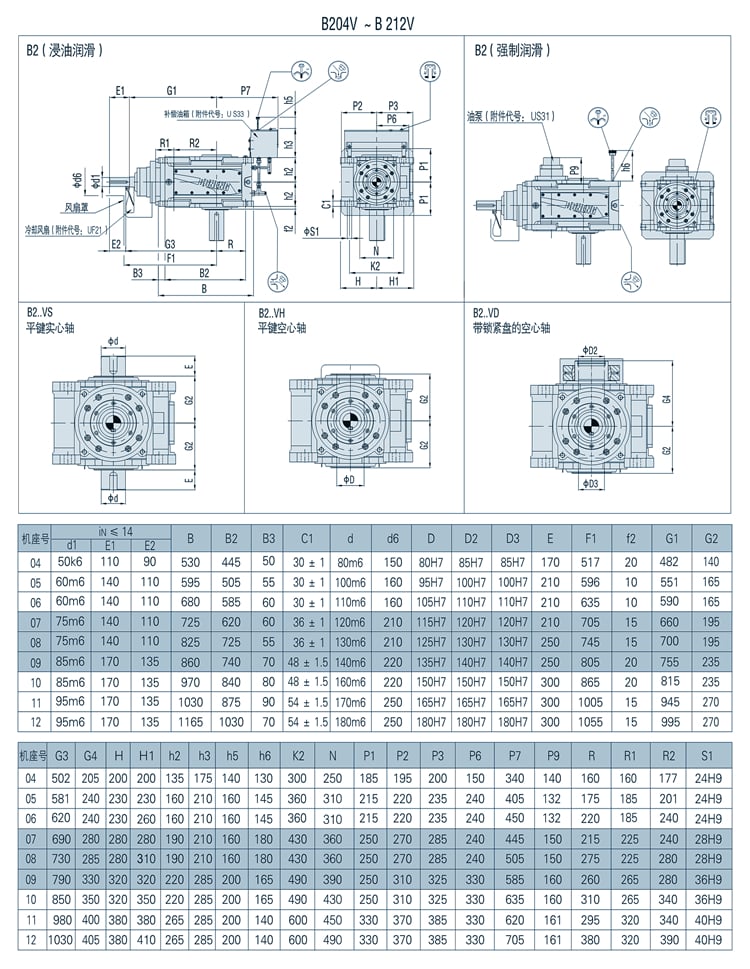

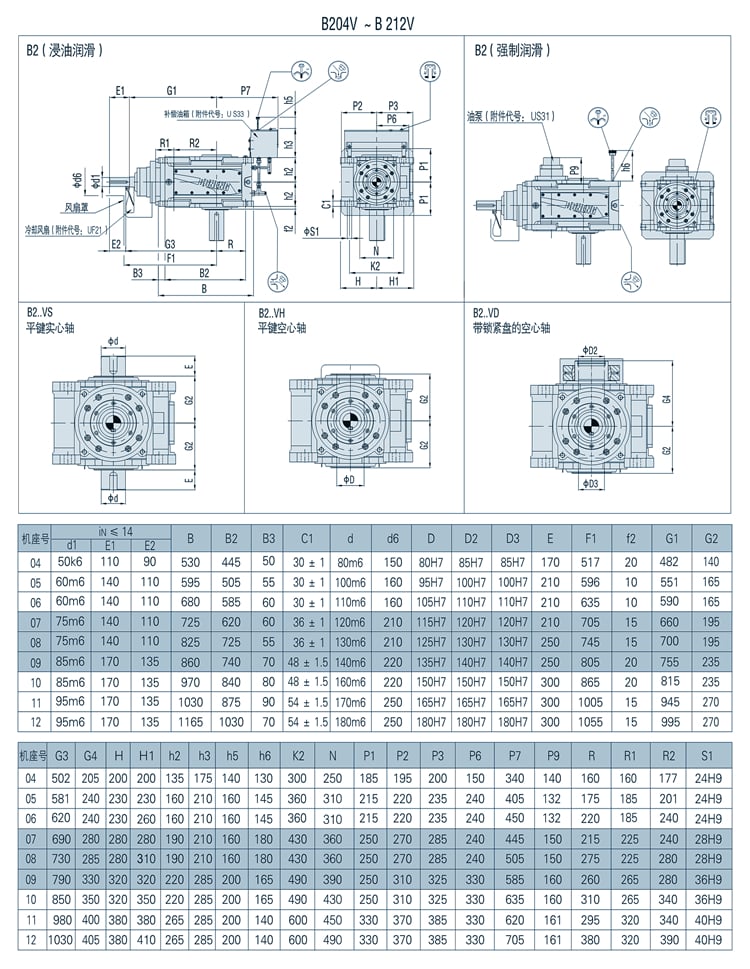

Specification

H B Series:

(you should contact us for a lot more varieties & model)

| Kind | n r/min |

Transmission Ratio (i) |

Sort | n r/min |

Transmission Ratio (i) |

Sort | n r/min |

Transmission Ratio (i) |

Type | n r/min |

Transmission Ratio (i) |

| H1SH | 750 | 1.twenty five-2 | H2 B2 | 750 | five-nine | H3 B3 | 750 | 12.5-112 | H4 B4 | 750 | eighty-450 |

| 2.24-5.6 | 10-28 | 1000 | twelve.5-112 | a thousand | eighty-450 | ||||||

| 1000 | 1.25-two | 1000 | 5-nine | 1500 | twelve.5-31.five | 1500EPG manufacturer rotGirard DYN selection-2 Our selection of worm gearboxes is notably suited to demanding stepper and servo motor purposes.ocultivator ploughshares in T. line had been selected as the Nationwide Rotary Tillage Equipment Business “Best Manufacturer Items” in 2007 by Rotocultivator Branch of China Agricultural Equipment Sector Association. | eighty-112 | ||||

| two.24-5.6 | 10-28 | 35.5-fifty six | 125-450 | ||||||||

| 1500 | 1.twenty five-2 | 1500 | 5-6.three | sixty three-112 | |||||||

| four-5.6 | seven-9 | ||||||||||

| 10-sixteen | |||||||||||

| eighteen-28 | |||||||||||

Mounting Diamensions:

Model variety for washing equipment Gear Box Transmission:

Intently making use of the excellent reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft pace

Torque calculation: Torque calculation is quite critical for the life of reducer, and shell out attention to whether the maximum torque price (TP) of acceleration exceeds the maximum load torque of the reducer.

The relevant energy is typically the relevant power of the servo types on the marketplace, the applicability of the reducer is extremely substantial, the working coefficient can be managed earlier mentioned 1.2, but the decision can also be primarily based on their own needs to determine. industrial helical gearbox.OEM Substantial Torque Helical Equipment Speed Reducer. H B right angle helical bevel equipment box 90 diploma transmission gearbox kind for sliding gate.

Technological innovation

Chinese Speed Reducer/industrial helical gearbox is a mechanical transmission in numerous fields of the countrywide economy. The merchandise classes coated by the business incorporate all kinds of equipment reducer, planetary equipment reducer and worm gearbox, as nicely as numerous particular transmission devices such as pace growing unit, speed management Products, including different types of flexible transmission products, these kinds of as compound transmission. Goods and services in the subject of metallurgy, nonferrous metals, coal, creating resources, ships, water conservancy, electricity, design machinery and petrochemical industries.

In all fields of national economic climate and nationwide defense sector, gearbox products have a extensive variety of purposes. Foodstuff gentle business, electric powered machinery, construction machinery, metallurgy machinery, cement equipment, environmental safety machinery, digital appliances, road construction equipment, h2o conservancy equipment, chemical equipment, mining equipment, conveyor machinery, constructing materials machinery, rubber machinery, petroleum machinery and other industries have sturdy demand of Reducer goods. H B appropriate angle helical bevel gear box 90 degree transmission gearbox kind for sliding gate.

Packaging & Delivery

- one. Big Volecity- Minimizing Ratio:Ratio of solitary-phase pace-decreasing is 1/eleven-1/87 Ratio of double phase velocity-minimizing is 1/112-1/5133Ratio of 3-phase speed-minimizing is 1/2057-1/446571more-levels can be merged according to the requirement.

-

two. High driving performance:Due to adopting rolling engagement in falling-in element, the driving efficiency can get to earlier mentioned ninety%.

-

3. Small in size, mild fat: with compacted construction,small measurement and gentle fat. Because of to adopting the principle of earth driving so that the enter and output shaft in the very same axis which will built-in with the motor.H B proper angle helical bevel gear box ninety degree transmission gearbox kind for sliding gate

-

4. Long support existence: Has excellent resistance to abrasion because the main driving engaging elements are made of bearing steel and making use of rolling friction.

-

5. Stable working: for most driving method, we adopt multi-enamel slipping-in. Then the managing will be secure with reduced sounds.

-

6. Convenient dismounting:affordable structure and design and style.

-

seven. Strong overloading ability,anti-compact,ideal for frequently commence and double-aspect rotation.

Firm Details

Launched in 1995, HangZhou At any time-Electrical power Power machinery Co.,Ltd has 22 a long time of reducer manufacturing knowledge and trustworthiness. The firm has professional engineer crew, advanced technological innovation manufacturing and competent staff, with located in HangZhou of ZheJiang province which has solid industrial foundation and produced transportation.

FAQ

1.Q:Are you the manufacturing unit or buying and selling organization?

A:We are the expert Manufacturing facility with 22 many years of encounter.

two.Q:Can you personalize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

three.Q:How lengthy is the shipping and delivery date?

A:ten-twenty working days.

4.Q:The place is your manufacturing facility?

A:We are in HangZhou of ZheJiang Province, you can get below by substantial speed prepare or fly to Jinan.

Welcome to check out us!

Best China manufacturer & factory high quality Textile speed reducer reduction ratio 1.5 : 1-100 : 1 worm motor worm gear worm gearbox supplier With high quality best price

our products are selling well in the American, European, South American and Asian markets. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Bearing:

-

Bronze

- Housing Material:

-

Aluminum alloy

- Product name:

-

DEVO NMRV Series gearbox

- Mounting Position:

-

Flange Motunted

- Input Form:

-

Shaft Input

- Output Form:

-

while the types of yokes for the connection of the PTO shafts with the agricultural implement includes the same above splined yokes and also yokes with recessed button and/or ball collar with:

hollow Shaft Output

- Heat treatment:

-

Carburizing & Quenching

- Color:

-

Blue or silver

- Certificate:

-

ISO 9001

- Warranty:

-

Within our field of work is adapting our reducers from the catalogue to our costumer´s necessity by means of flanges, shafts, extensions, supports, etc. according to the necessities of their machines.

1 Year

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 10 >10 Est. Time(days) 15 To be negotiated

Online Customization

EPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting tools.

Product Description

Introductions of NMRV Series Worm Gear Reducer

The NMRV worm gear reducer is equipped with high quality aluminum alloy casting and it adopts the advanced square box structure which is small in size, light in weight and beautiful in apperance. The worm gear reducer could be matched with other gearboxes to reach a large ratio and torque. What’s more, due to the small size of the gearbox, it is easy to install and maintain. The NMRV worm gearboxes are manufactured with international technical requirements and possess a high technological content which guarantee the high rigity and high torque.

Structure Drawing of NMRV Series

|

|

Advantages of NMRV Worm Gearbox |

||||||

|

Low noise |

This worm gearbox is smooth in transmission which is suitable for working in harsh environment for a long time. |

||||||

|

High efficiency |

With the using of tin bronze worm gear material, this worm gear reducer is low in temperature-rising and fast in heat dissipation. |

||||||

|

High quality |

The reducer made of cast iron which casted with Aluminum mould. It`s good looking and solid, and can be used through the setting |

||||||

Parameter Table of NMRV

HIGH QUALITY HOUSING AND BEARING MATERIAL

The reducer is made of cast iron which casted with Aluminum mould. It`s good looking and solid, and can be used through the setting of multi-azimuth

NMRV SERIES WORM GEAR SPEED REDUCER MOUNTING DIMENSIONS

Dimension Diagram of NMRV 50

Profile of Our Company

Our company is located in the city of Xuzhou, ZJ Province of China. We handle the products of power

transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and

other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields:

machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper

industry, cement industry, cableways and so on.

With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the

peers all over the world. We always innovate for the purpose of better meeting the new demands of our customers and

adapting the new tendency of the industry. Depending on the principles of honestly operating and mutual benefit, We

sincerely look forward to cooperating with you.

Application Field

Packing & Delivery

PACKING AND TRANSPORTION

● Packaging: In order to ensure the integrity of product appearance, we will choose cartons, wooden pallets and wooden pallets according to customer needs.

● Delivery time: Each reducer is manufactured and tested in accordance with strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

● Transportation modal: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

● Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

FAQ

Best China manufacturer & factory china supplier ZSY type china transmission helical gear box small marine gearbox With high quality best price

Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Pole:

-

Single Two Three Stage Speed Reducer

- Ratio:

-

1.25-100

- Housing Material:

-

Cast Iron

- Working temperature:

-

-40~45℃

- Application:

-

for agricultural machinery mining, chemical industry,steel ,lifting

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

94%~98%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Green,Gray,Red

- type:

-

ZSY type china transmission cylindrical gear box small marine gearbox

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 1 >1 Est. Time(days) 15 To be negotiated

Online Customization

Product Description

YOUR PROFESSIONAL MANUFACTURE

—— SINCE 1995

Z Series Helical Gear Reducer

Z (ZDY, ZLY, ZSY, and ZFY) serieshard tooth surface cylindrical gear reducer

D (DBY and DCY) series hard tooth surface cone gear reducer

ZSY type china transmission helical gear box small marine gearbox

Chinese speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, etc. Meanwhile, map sample processing business can be undertaken.

AND HI-TECH GEARING TECHNOLOGY Our Fellbach plant offers optimal engineering and manufacturing facilities for special gearboxes and gearing – from conception through to serial production.Feature:

-

Applicable to the metallurgical,power generation,water treatment,construction,chemical,paper,

textiles,medicine,food and other industries.

-

The transmission efficiency of single-stage can reach up to 98%, two-stage can reach 96%, three-stage can reach 94%.

-

The gear processed by Carburizing & Grinding with high precision.

-

High precision gear, steady transmission, large load capacity

-

Long service life.

- One Two Three Stage Speed Reducer

Specification

ZSY type china transmission helical gear box small marine gearbox:

(please contact us for more types & model)

| Driven machines | |||

| WasMaintenance Maintenance on these units is straight forward and like all moving parts these need their fair share of grease and should be greased regularly as these components work very hard and are subject to all that nature can provide for wear and tear. Good grease is essential here; put grease in until you see the old grease oozing out. Go easy on the “U” joints so you don’t blow the seals. Short bursts of a low pressured air grease gun or even better a hand pump gun will do the job and should be done based on hourly use. At least once a season the primary and secondary shafts should be separated. All debris and any rust should be cleaned off. Examine thoroughly for any signs of stress and apply a liberal amount of grease. In addition to this, both the PTO yoke holes need grease inside of them at least once a year along with the yoke lock pin.te water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing blooming mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Model selection:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. ZSY series two stage cylindrical transmission reducer for belt conveyor. ZLY series 2 stage helical speed reducer for paper mill.1 10 ratio gearbox speed reducer for plastic extruder machine. ZSY type china transmission cylindrical gear box small marine gearbox.

Technology

Chinese Electric Motor Gear Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products. ZSY series two stage cylindrical transmission reducer for belt conveyor. ZLY series 2 stage helical speed reducer for paper mill. 1 10 ratio gearbox speed reducer for plastic extruder machine. ZSY type china transmission cylindrical gear box small marine gearbox.

Packaging & Shipping

Company Information

Founded in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 years of reducer production experience and credibility. The company has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

The company was certified by ISO9001:2008 Quality Management System. A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

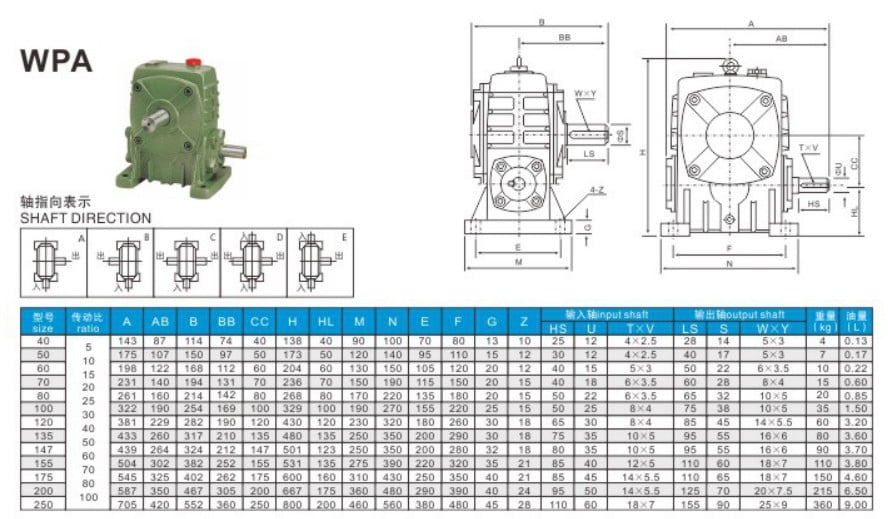

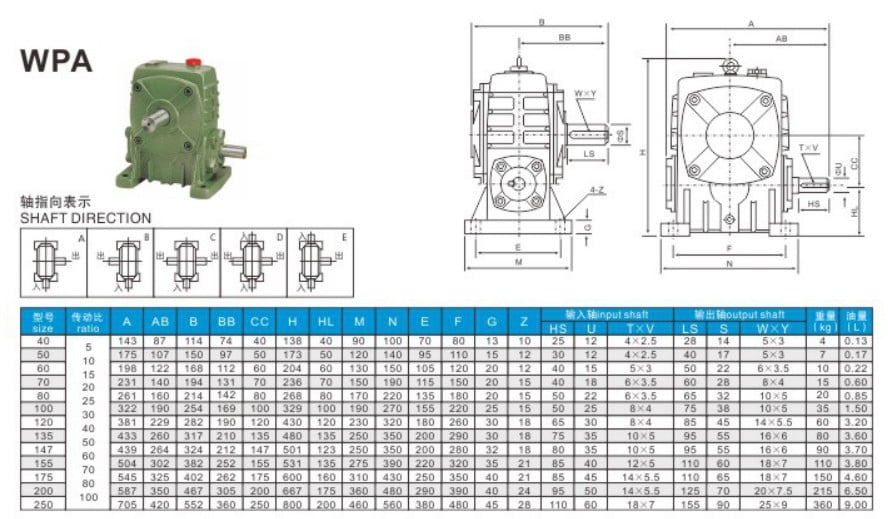

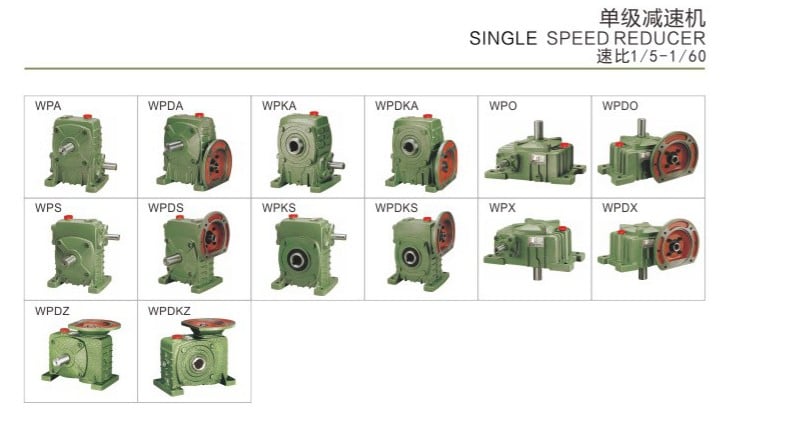

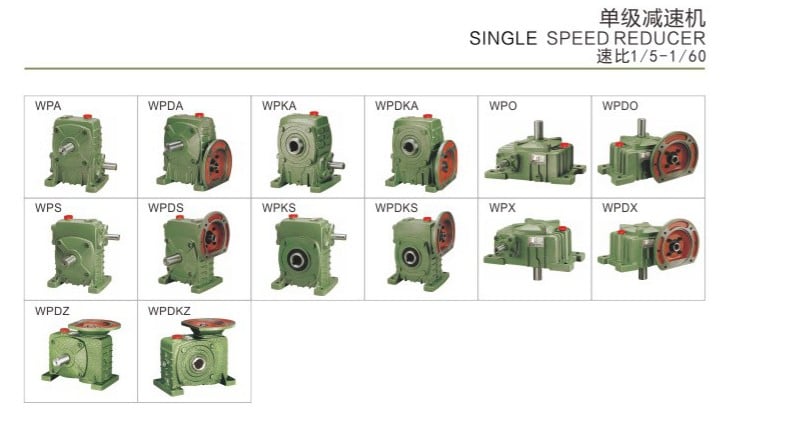

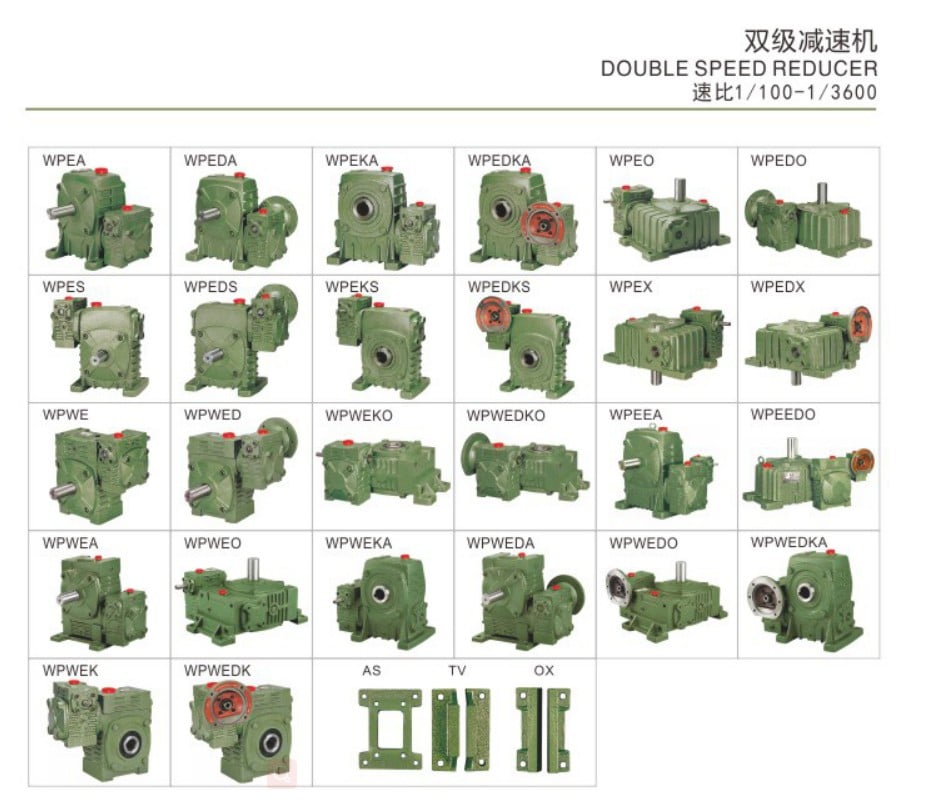

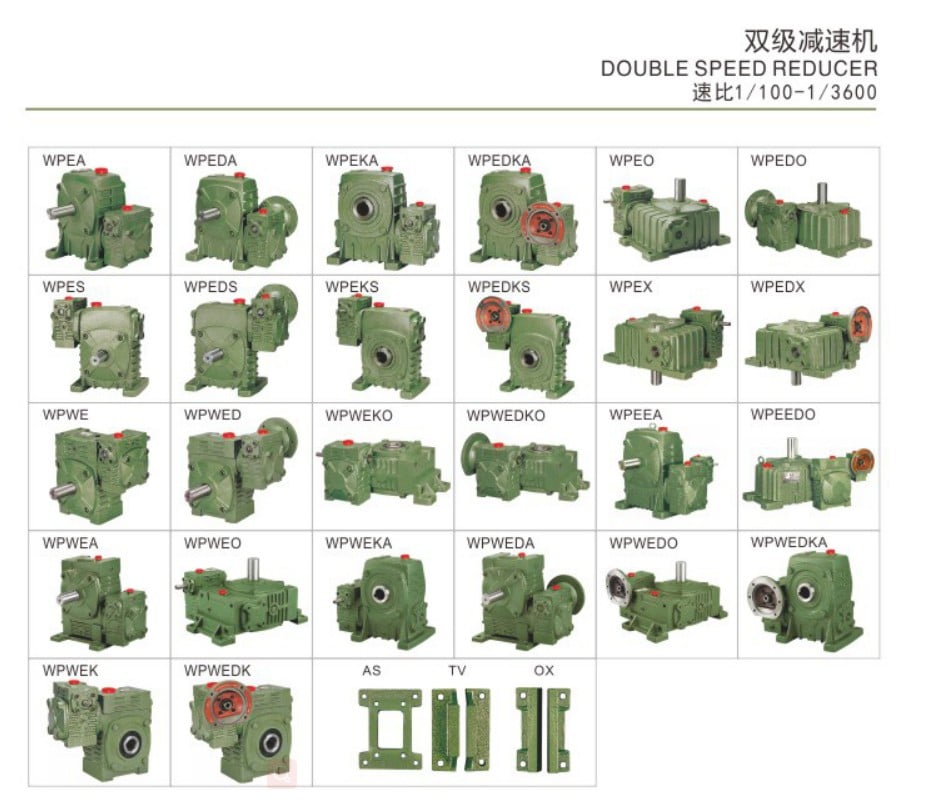

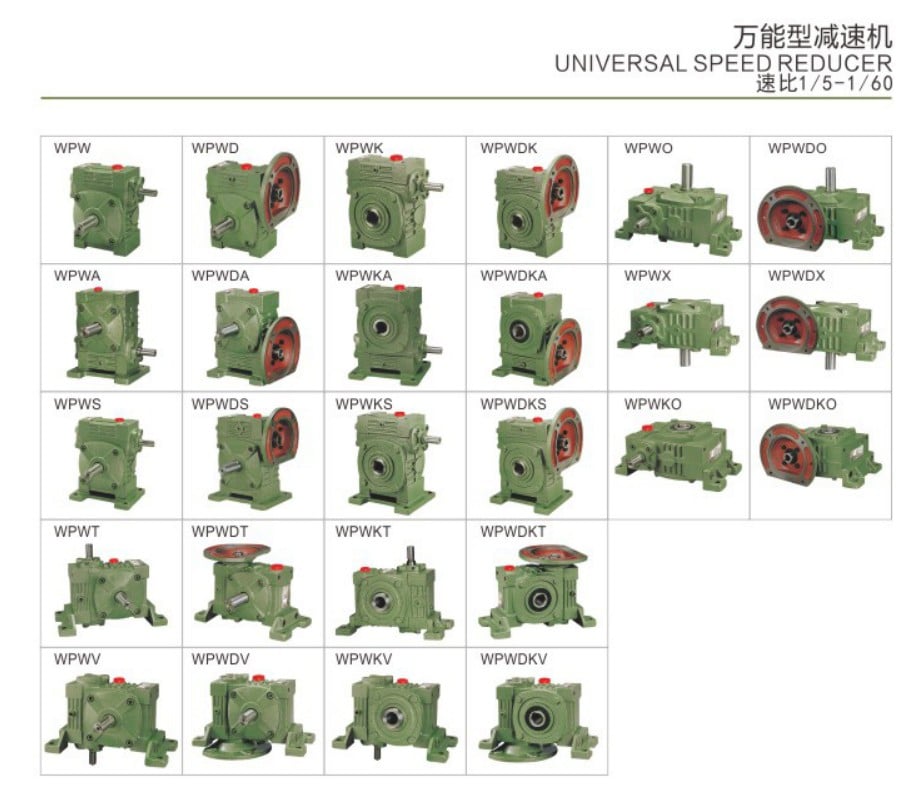

Best China manufacturer & factory High efficiency worm gearbox wpa reducer small gear box gearbox to increase rpm light box reducer transmission With high quality best price

EPG is a professional manufacturer and exporter that is concerned with the design, development and production.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

1.8-2430N.M

- Input Speed:

-

1400rpm

- Output Speed:

-

19-186.7rpm

- Place of Origin:Zhejiang, China

- Accudrive Servo Gearheads Servo drives from EPG Drive benefit from the expertise and innovation of our more traditional brands. Available in both right angle and inline configurations, coupled with the availability of multiple precision levels, you are sure to find the right product for your application.EPG Drive Accudrive Servo Gearhead Brand Name:

-

OEM

- Color:

-

silver, blue, black and so on

- speed ratio:

-

5,10,20,30,40,50,60,70,80,100

- size:

-

40

-

MOQ:

Shear bolt torque limiter (SB) EPG GROUP offers high quality PTO shafts with tubes fixed by spring pin, cross joints with roller bearings with rollers -

1pcs

- other size:

-

please contact Connie Chen

- shaft direction:

-

A,B,C,D,E

Packaging & Delivery

-

Lead Time

: -

Quantity(Boxes) 1 – 1 >1 Est. Time(days) 15 To be negotiated The company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CAD/CAM system, industrial robot etc.

Online Customization

High efficiency worm gearbox wpa reducer small gear box gearbox to increase rpm manchester united light box reducer transmission

Product Description

Main Features

1.Housing:iron cast

2. low noise(<50DB)

3.Model:WPDA 40-250,Ratio:10 to 60

4.Efficient and safe operating

Company Information

Quality control

Our Certifications

Related Product

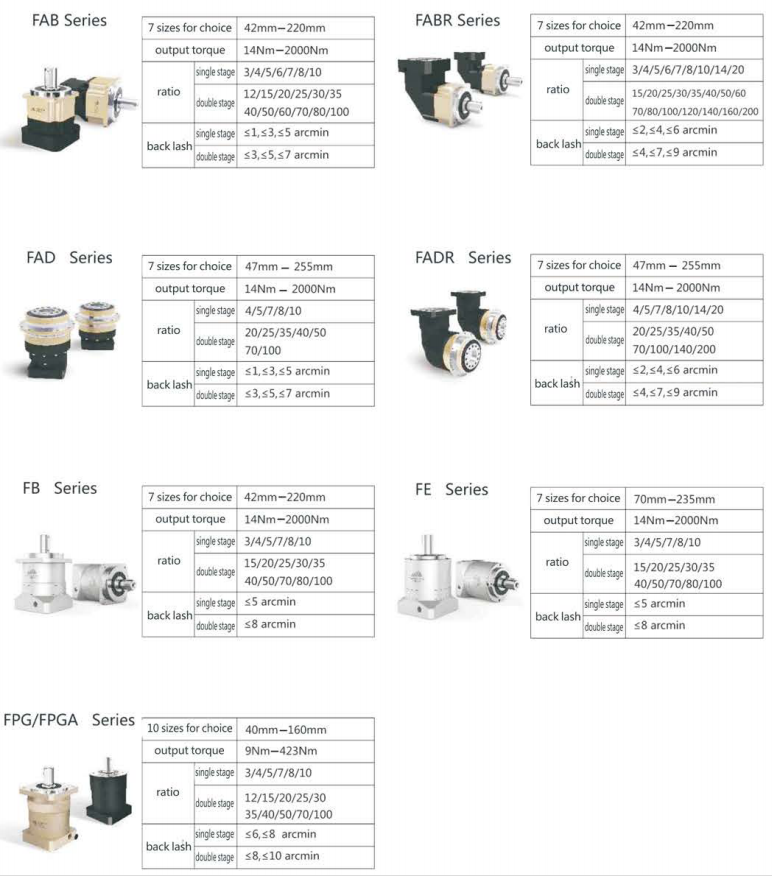

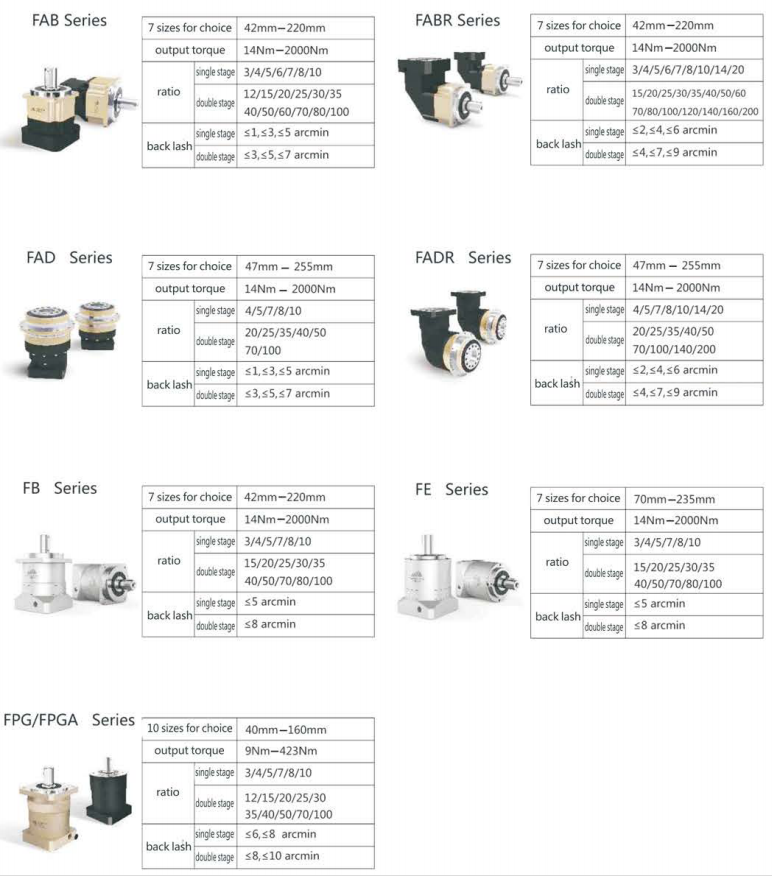

Precision Planetary gearbox

FAQ

1.Payment Term: TT, L/C

2.Delivery time: about 30 days from receive payment.

3.We accept customized products as per your special requirement.

4.Guidelines for the Selection:Usually we can select one machine which is suitable for you with some informations from you,such as ratio/motor speed/mounting dimension/ out torque etc.

5.If the minimum order amount is in excess of $10000, there are preferential.

Q1: What information should I tell you to confirm the product?

A:Model/Size, Transmission Ratio, Shaft directions & Order quantity.

Q2: What can i do if I don’t know which one I need?

A:Dont worry, Send as much information as you can, our team will help you find the right one you are looking for.

Q3: What is your product warranty period?

A:We offer one year warranty since the vessel departure date left China.

Q4: Are you trading company or manufacturer ?

A: We are factory.

Q5: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q6: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q7: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact Us

Best China manufacturer & factory All china price parallel shaft gearbox F57 FA57 FAF57 FF57 helical gear reductor with 3hp motor With high quality best price

In 2008, it was awarded with “National Export Commodity Inspection-free Enterprise”.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- ITEM NO:

-

SYF

- Mounting Position:

-

Foot Mounted. Flange Mounted

- Ratio:

-

1.3-58800

- Bearing:

-

NSK Bearing

- Warranty:

-

1-2 Years

- Certificate:

-

ISO9001

- Input speed:

-

0-3000rpm/min

- Output speed:

-

0.1-356rpm/min

- Output torque:

-

0-18000N.m

- Motor power:

-

0.18-11kw

Packaging & Delivery

-

Lead Time

: -

Quantity(Pieces) 1 – 1 Gear-reducer inefficiency converts power to heat. AGMA ( American Gear Manufacturers Assn.) guidelines for worm-gear, helical, and other types of reducers limit the maximum allowable operating temperature to 100°F above ambient, not to exceed 200°F. To stay within these guidelines, worm-gear reducers must be considerably larger than equivalent-rated helical reducers (to dissipate more heat) or rely on auxiliary cooling devices.

2 – 5 6 – 10 >10 Est. Time(days) 5 10 15 To be negotiated

Online Customization

Product Description

F SERIES PARALLEL SHAFT HELICAL GEAR REDUCER

F series parallel shaft helical gear reducer has the characteristics of small volume, light weight, large transfer torque, low energy consumption, high efficiency, low temperature rise, strong load force and various structure forms. Suitable for different installation conditions.

It can be combined with R series, K series, S series, etc. to obtain lower speed and greater torque.

F SERIES STRUCTURE DRAWING

|

OUTPUT SPEED: |

0.1~356 r/min |

|

OUTPUT TORQUE: |

≤18000 N.m |

|

POWER: |

0.18~11kw |

|

MOUNTING TYPE: |

Foot-mounted Foot-mountedEPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting tools. and Hollow- mounted Hollow-shaft B5 Flange-mounted B5 Flange-mounted and Hollow- mounted B14Flange-mounted and Hollow- mounted |

PRECISION BEVEL GEAR

20CrMn Ti material – low carbon alloy steel

Imported gear grinding machine processing, high hardness, stable performance.

Vacuum furnace carburizing heat treatment, carburizing layer uniform.

HIGH QUALITY SHELL MATERIAL

The box body is made of HT200 material,which is cleaned by professional screening and washing equipment to ensure that the inner cavity of the box body is cleaner without iron filings.

HIGH QUALITY OUTPUT SHAFT

New standard axle, multi-precision machining, through rigorous dynamic and static balance test, to ensure low noise and smooth operation of reducer

PROFESSIONAL AIR TIGHTNRSS TEST

Before spraying each reducer, air tightness test is needed to minimize the occurrence of oil leakage and air leakage. Ensure the long life and good operation of the reducer.

F SERIES HELICAL GEAR UNITS OVERVIEW:

●Parallel output,structure compact,carrying bigger torque,operation stable,voice low,lifetime long.

●Mounting mode :foot-mounted,flange-mounted,torque arm-mounted.

●Ratio:ratio of 2-stage is 8.1-191,ratio of 3-stage is 28.2-273,ratio of combination is up to 18509.

●For 2-stageOur PTO drive shafts enable the user easy maintenance. The greasing nipples on standard crosses are positioned under angle to enable the user better access. Easier access is also possible because of the flexible cone. We listened to the wishes of our customers and placed the greasing nipple at wide-angle PTO’s into the cross bearing. The other novelty, we introduced with wide-angle PTO drive shafts is in line greasing. We wanted to additionally simplify the maintenance and extend the lifespan of joints. basic type geared,rotation direction of input shaft is the same that of output shaft;for 3-stage basic type geared,their directions are reverse;for combination,please contact Ever Power.

●Output mode:hollow shaft output or solid shaft output.

●Average efficiency: 2-stage 96%, 3-stage 94%,combination 85%.

F SERIES PARALLEL SHAFT HELICAL GEAR REDUCER MOUNTING DIMENSIONS OUTPUT SHAFT DIMENSIONS

F foot shaft mounting parallel helical gear reducer

FA hollow shaft mounting parallel shaft helical gear reducer

FF flange shaft mounting parallel shaft helical gear reducer

Our Company

HANGZHOU EVER-POWER GROUP, ONE OF THE BIGGEST GEARBOX FACTORY IN CHINA, ELECTROMECHANICAL EQUIPMENT SUPPLY STATION

Our company is located in the city of HangZhou, ZheJiang Province of China.

We handle the products of power transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields: machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper industry, cement industry, cableways and so on.With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers all over the world.

Furthermore, the R&D investment are annually increasing for the purpose of better meeting the new demands of our customers and adapting the new tendency of the industry.

Depending on the principles of honestly operating and mutual benefit, We sincerely look forward to cooperating with you.

Application area

Certifications

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In order to ensure the integrity of product appearance, we will choose cartons, wooden pallets and wooden pallets according to customer needs.

●Delivery time: Each reducer is manufactured and tested in accordance with strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

●Transportation mode: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

●Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

FAQ

Q1: Are you a trading company or a manufacturer ?

A: We are a manufacturer in ZheJiang Province, China. Our company owns the ability of manufacturing, processing,designing and R&D. We welcome your visit.

Q2: How we select models and specifications?

A: According to the specific details of the demands from the part of enquiry, we will recommend the products’ models upon synthesizing the factors of field of products usage, power, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our prices are always competitive. If the customer can place a large order, we surely will allow discount.

Q4: How long should I wait for the feedback after I send the enquiry?

A4: We will reply the enquiries without any delay, 12 hours at most.

Q5: What is your product warranty period?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes being used?

A: Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

Hot-sale Product

Best China manufacturer & factory high performance valve worm gear box or bevel gearbox With high quality best price

our products are selling well in the American, European, South American and Asian markets. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

Adding a second engine simply is not practical, which makes power take off (PTO) a valuable element in providing power to secondary functions. To recognize their value requires a better understanding of these systems, their various types, and their various applications.

- Model Number:

-

SYF

- Certificate:

-

ISO9001:2015

- Operation:

-

handwheel operated

Supply Ability

- Supply Ability:

- 9999 Bag/Bags per Day

Packaging & Delivery

- Port

- ningbo/shanghai

-

Lead Time

: -

Quantity(Pieces) 1 – 9999 >9999 Est. Time(days) 12 To be negotiated

Online Customization

Product Description

Worm gearbox spare parts for plug valve hot selling wholesale

Product Feature

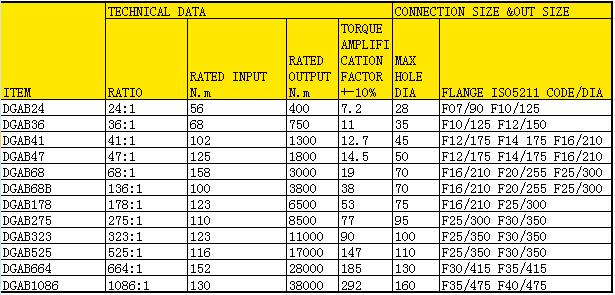

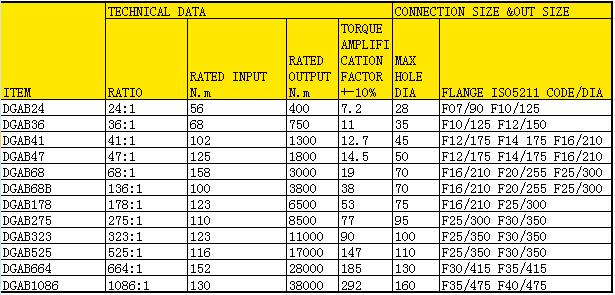

GBAB series all have 11 sizes,ratio from 24:1-1086:1 /torque range from 430N.m-41000N.m /the oil inside housing used for long time/ ISO 5211 flange connection /each size match several flange/. GB/T 1095 standard keyseater /rotation(+-5 adjustable)/ temperature range:-2℃–+120℃/IP68/Housing: casting iron or steel

Applied Field

widely used on ball valve ,butterfly valve and plug valve in the field of Gas/Oil/Water/Others.

| DGAB SERIES | |||

| serial | material | standard No./code | |

| 1 | body | cast iron | ASTM A536 65-45-12 ASTM A216 EPGB |

| 2 | body cover | cast iron | ASTM A536 65-45-12 ASTM A216 EPGB |

| 3 | worm gear | cast iron | ASTM A536 65-45-12 |

| 4 | worm stem | carbon steel | ASTM A29 1045 |

| 5 | indicator plate | aluminium | – |

| 6 | gear | carbon steel | ASTM A29 1045 |

| 7 | input shaft | carbon steel | ASIn close consultation with the customer, the design of special gearboxes and high-precision gearing components are individually customized to the technical and operational requirements. For special requirements such as HIGH SPEED, low noise or HIGH TORQUE, we develop optimal customer solutions thanks to our many years of experience and expertise. Furthermore, we provide support in the assessment of load tests and product engineering optimization. Owing to our steadily developing expertise, this results in tailor made high-end solutions, which we produce in-house.TM A29 1045 |

| 8 | bearing | hardening steel | – |

| 9 | sleeve | composite | – |

| 10 | adjust bolt | carbon steel | 8.8grade |

| 11 | seal | rubber | NBR |

| 12 | fastener | carbon steel | 8.8 grade |

Company ProEPG brand rotocultivator ploughshares in T. line were selected as the Nationwide Rotary Tillage Machinery Industry “Perfect Brand Products” in 2007 by Rotocultivator Branch of China Agricultural Machinery Industry Association. file

Ever-Power Group one of the biggest transmission producer – valve drive co.,ltd mainly produce different sizes of worm gear box more than 10years since year 2009,which widely used on ball valve ,butterfly valve and plug valve in the field of Gas/Oil/Water/Others.we have professional team and advanced machine to check the technic and control the quality,in the last years our worm gear box sale rank Top 3 in the world.Ever-Power Group one of the biggest transmission producer – win reputation for both demestic and outside & have get ISO9001 Quality Management System ,Welcome have business with us!

Certificate

Exhibition

Production Process

Package & Shipment

Our Advantages