Product Description

Gravity die-casting

Specification:

Gravity die casting

1. Open mould

2. Die casting

3. Casting (trim, grind, drill)

4. Surface treatment( anodize, chrome-plated)

Gravity die casting

Technological processed: Open mould— die casting —-casting (trim, grind, drill) —surface treatment

Gravity die casting detail:

1. Material: Aluminum (A380, A360, ADC12, ADC10) according to JISH5302: 2006 &ASTM

2. Process: Trim grind, drill, CNC

3. Surface treatment: Shot blashing, sandblasting or painting, anodize, electroplating, chrome-plated or all per customers’ requirement

Gravity die casting design & mold manufacture

2. Use the software: Auto CAD, RPO/Engineer, Solidwork, UG

3. Mold design

4. Trial the mold

5. Machine: EDM, CNC, Grinding Machine, Milling Machine, Tuning Machine, Wire Cutting Machine, Photo Engraving, Chemical Milling, Welder

| Item | description |

| type | Aluminum die casting Zinc die casting Magnesium die casting |

| manufature | HangZhouxinlong CZPT trade co., ltd |

| equipment | Cold chamber die casting machine |

| Machine capacity | 100T-800T |

| process | Tooling making: 20-30days tooling leadtime Casting: remove all burrs & sharp edges Machinng: CNC maching, milling, drilling, trimming, cutter, griding, wire cutter etc Surface treatment: shot blasting, sand blasting Polishing, powder coating, painting, , polishing, powder coating, chrome plating, nickel plating, passivating |

| Quality control | first checked after cast from die casting machine second checked by the warehouse people third checked after machining and surface finish. We check piece by piece each time |

| package | inner packing: PE bag or air bubble bag outer packing: double corrugated carton as per customers’ requirment |

| advantage | OEM service offered Send us you RFQ in details! We produce strictly according to customer’ s design and machining request. |

| Condition: | New |

|---|---|

| Certification: | CE, RoHS, GS, ISO9001 |

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Material: | Aluminum |

| Application: | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What Are the Advantages of a Splined Shaft?

If you are looking for the right splined shaft for your machine, you should know a few important things. First, what type of material should be used? Stainless steel is usually the most appropriate choice, because of its ability to offer low noise and fatigue failure. Secondly, it can be machined using a slotting or shaping machine. Lastly, it will ensure smooth motion. So, what are the advantages of a splined shaft?

Stainless steel is the best material for splined shafts

When choosing a splined shaft, you should consider its hardness, quality, and finish. Stainless steel has superior corrosion and wear resistance. Carbon steel is another good material for splined shafts. Carbon steel has a shallow carbon content (about 1.7%), which makes it more malleable and helps ensure smooth motion. But if you’re not willing to spend the money on stainless steel, consider other options.

There are two main types of splines: parallel splines and crowned splines. Involute splines have parallel grooves and allow linear and rotary motion. Helical splines have involute teeth and are oriented at an angle. This type allows for many teeth on the shaft and minimizes the stress concentration in the stationary joint.

Large evenly spaced splines are widely used in hydraulic systems, drivetrains, and machine tools. They are typically made from carbon steel (CR10) and stainless steel (AISI 304). This material is durable and meets the requirements of ISO 14-B, formerly DIN 5463-B. Splined shafts are typically made of stainless steel or C45 steel, though there are many other materials available.

Stainless steel is the best material for a splined shaft. This metal is also incredibly affordable. In most cases, stainless steel is the best choice for these shafts because it offers the best corrosion resistance. There are many different types of splined shafts, and each one is suited for a particular application. There are also many different types of stainless steel, so choose stainless steel if you want the best quality.

For those looking for high-quality splined shafts, CZPT Spline Shafts offer many benefits. They can reduce costs, improve positional accuracy, and reduce friction. With the CZPT TFE coating, splined shafts can reduce energy and heat buildup, and extend the life of your products. And, they’re easy to install – all you need to do is install them.

They provide low noise, low wear and fatigue failure

The splines in a splined shaft are composed of two main parts: the spline root fillet and the spline relief. The spline root fillet is the most critical part, because fatigue failure starts there and propagates to the relief. The spline relief is more susceptible to fatigue failure because of its involute tooth shape, which offers a lower stress to the shaft and has a smaller area of contact.

The fatigue life of splined shafts is determined by measuring the S-N curve. This is also known as the Wohler curve, and it is the relationship between stress amplitude and number of cycles. It depends on the material, geometry and way of loading. It can be obtained from a physical test on a uniform material specimen under a constant amplitude load. Approximations for low-alloy steel parts can be made using a lower-alloy steel material.

Splined shafts provide low noise, minimal wear and fatigue failure. However, some mechanical transmission elements need to be removed from the shaft during assembly and manufacturing processes. The shafts must still be capable of relative axial movement for functional purposes. As such, good spline joints are essential to high-quality torque transmission, minimal backlash, and low noise. The major failure modes of spline shafts include fretting corrosion, tooth breakage, and fatigue failure.

The outer disc carrier spline is susceptible to tensile stress and fatigue failure. High customer demands for low noise and low wear and fatigue failure makes splined shafts an excellent choice. A fractured spline gear coupling was received for analysis. It was installed near the top of a filter shaft and inserted into the gearbox motor. The service history was unknown. The fractured spline gear coupling had longitudinally cracked and arrested at the termination of the spline gear teeth. The spline gear teeth also exhibited wear and deformation.

A new spline coupling method detects fault propagation in hollow cylindrical splined shafts. A spline coupling is fabricated using an AE method with the spline section unrolled into a metal plate of the same thickness as the cylinder wall. In addition, the spline coupling is misaligned, which puts significant concentration on the spline teeth. This further accelerates the rate of fretting fatigue and wear.

A spline joint should be lubricated after 25 hours of operation. Frequent lubrication can increase maintenance costs and cause downtime. Moreover, the lubricant may retain abrasive particles at the interfaces. In some cases, lubricants can even cause misalignment, leading to premature failure. So, the lubrication of a spline coupling is vital in ensuring proper functioning of the shaft.

The design of a spline coupling can be optimized to enhance its wear resistance and reliability. Surface treatments, loads, and rotation affect the friction properties of a spline coupling. In addition, a finite element method was developed to predict wear of a floating spline coupling. This method is feasible and provides a reliable basis for predicting the wear and fatigue life of a spline coupling.

They can be machined using a slotting or shaping machine

Machines can be used to shape splined shafts in a variety of industries. They are useful in many applications, including gearboxes, braking systems, and axles. A slotted shaft can be manipulated in several ways, including hobbling, broaching, and slotting. In addition to shaping, splines are also useful in reducing bar diameter.

When using a slotting or shaping machine, the workpiece is held against a pedestal that has a uniform thickness. The machine is equipped with a stand column and limiting column (Figure 1), each positioned perpendicular to the upper surface of the pedestal. The limiting column axis is located on the same line as the stand column. During the slotting or shaping process, the tool is fed in and out until the desired space is achieved.

One process involves cutting splines into a shaft. Straddle milling, spline shaping, and spline cutting are two common processes used to create splined shafts. Straddle milling involves a fixed indexing fixture that holds the shaft steady, while rotating milling cutters cut the groove in the length of the shaft. Several passes are required to ensure uniformity throughout the spline.

Splines are a type of gear. The ridges or teeth on the drive shaft mesh with grooves in the mating piece. A splined shaft allows the transmission of torque to a mate piece while maximizing the power transfer. Splines are used in heavy vehicles, construction, agriculture, and massive earthmoving machinery. Splines are used in virtually every type of rotary motion, from axles to transmission systems. They also offer better fatigue life and reliability.

Slotting or shaping machines can also be used to shape splined shafts. Slotting machines are often used to machine splined shafts, because it is easier to make them with these machines. Using a slotting or shaping machine can result in splined shafts of different sizes. It is important to follow a set of spline standards to ensure your parts are manufactured to the highest standards.

A milling machine is another option for producing splined shafts. A spline shaft can be set up between two centers in an indexing fixture. Two side milling cutters are mounted on an arbor and a spacer and shims are inserted between them. The arbor and cutters are then mounted to a milling machine spindle. To make sure the cutters center themselves over the splined shaft, an adjustment must be made to the spindle of the machine.

The machining process is very different for internal and external splines. External splines can be broached, shaped, milled, or hobbed, while internal splines cannot. These machines use hard alloy, but they are not as good for internal splines. A machine with a slotting mechanism is necessary for these operations.

editor by CX 2023-07-13

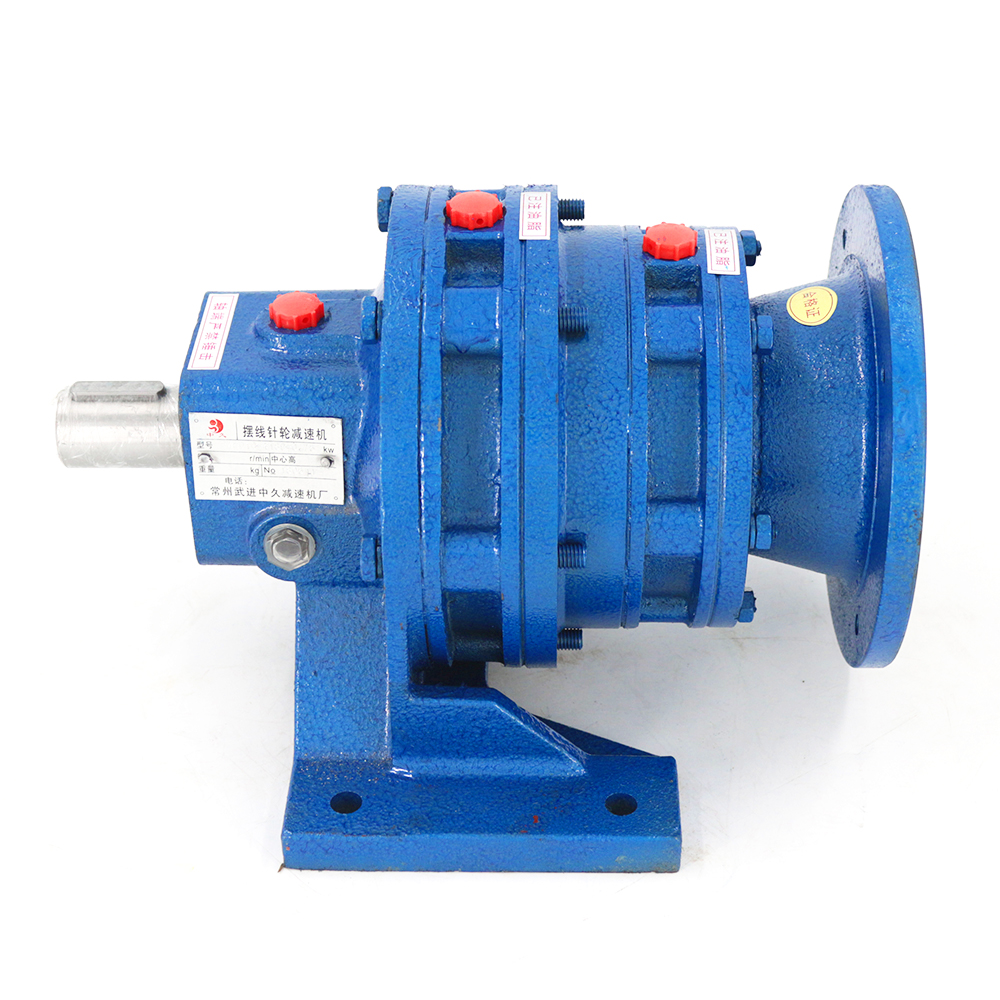

Best China manufacturer & factory Best in Duisburg Germany price bwd cycloid gearbox reducer BWED5 double reduction gearbox for mixer With high quality best price

EPG is a professional manufacturer and exporter that is concerned with the design, development and production.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- ITEM NO:

-

SYF

- Name:

-

planetary gearbox

- Application:

-

Drive or reduce gear

- Color:

-

blue

- Material:

-

Steel

- Certificate:

-

ISO9001

- Ratio:

-

9-28800

- Mounting Position:

-

Horizontal (foot Mounted)

- Bearing:

-

NSK

- Usage:

-

transportation, food, printing, lifting, mining

Packaging & Delivery

-

Lead Time

: -

Quantity(Pieces) Worm-gear speed reducers have offered a rugged, adaptable, and cost-effective method of power transmission for nearly a century. But their acceptance in The EPG GROUP range of PTO shafts accessories includes various types of yokes for the connection of the tractor power take-off with recessed push button and/or ball collar and/or ball collar for constant velocity joints, with the following spline dimensions: 1”3/8 Z6 – 1”3/8 Z6 -1”3/8 Z21- 1”3/4 Z6- 1”3/4 Z20recent years has been somewhat diminished by inherent inefficiency and a reputation for eventually developing oil leaks. Extensive research into these two related issues has pinpointed several contributing factors:

1 – 1 2 – 5 >5 Est. Time(days) 3 10 To be negotiated

Online Customization

Product Description

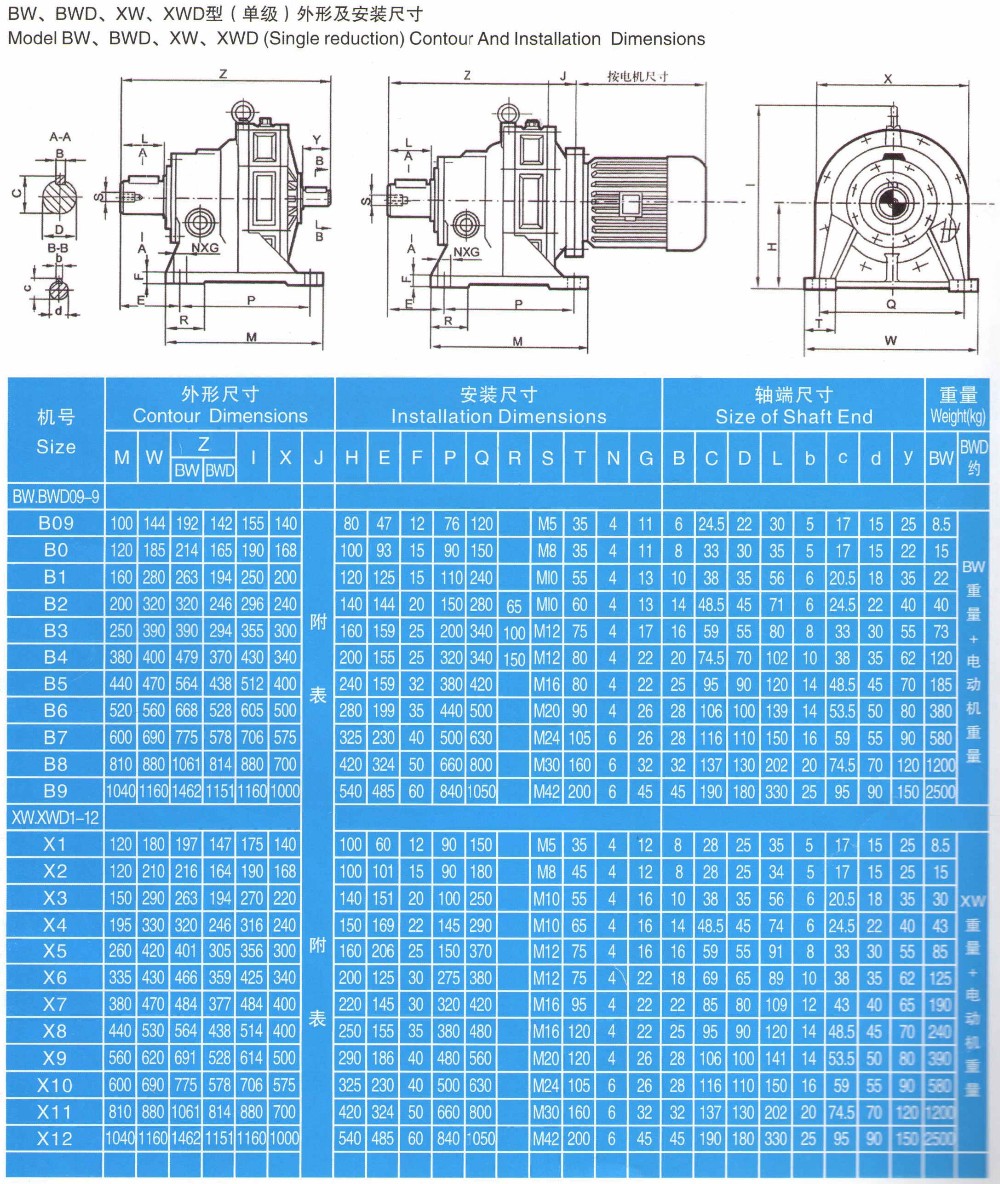

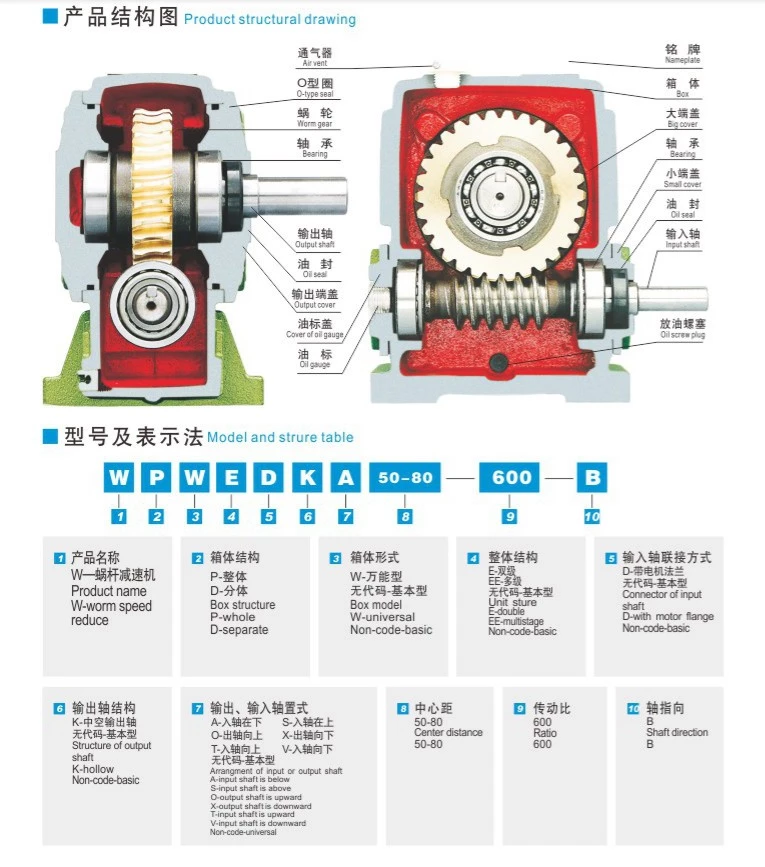

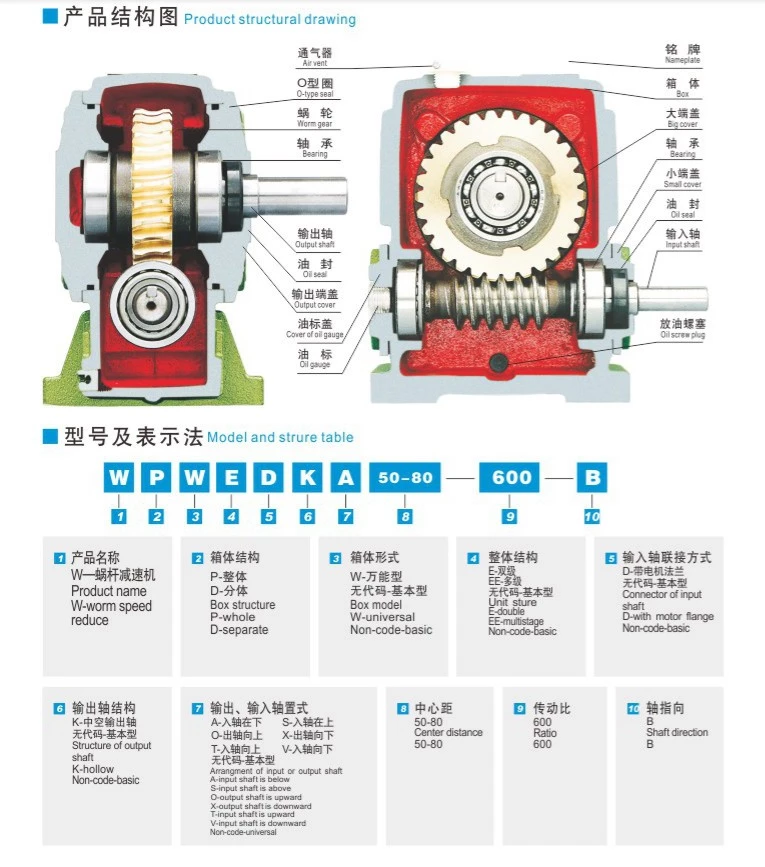

Cycloidal gear reducer is a principle adopted K-H-V Planetary Gear less innovative gear. Its transmission process as follows : input shaft equipped with a 180-degree dislocation of the double eccentric sets, replaced with two eccentric turn as a roller bearing arm, the formation of H-, two cycloid round hole at the center shall uplink Eccentric Roller Bearings arm, which cycloidal gear needle round and meshing phase, comprising a difference of the teeth meshing with the gearbox.

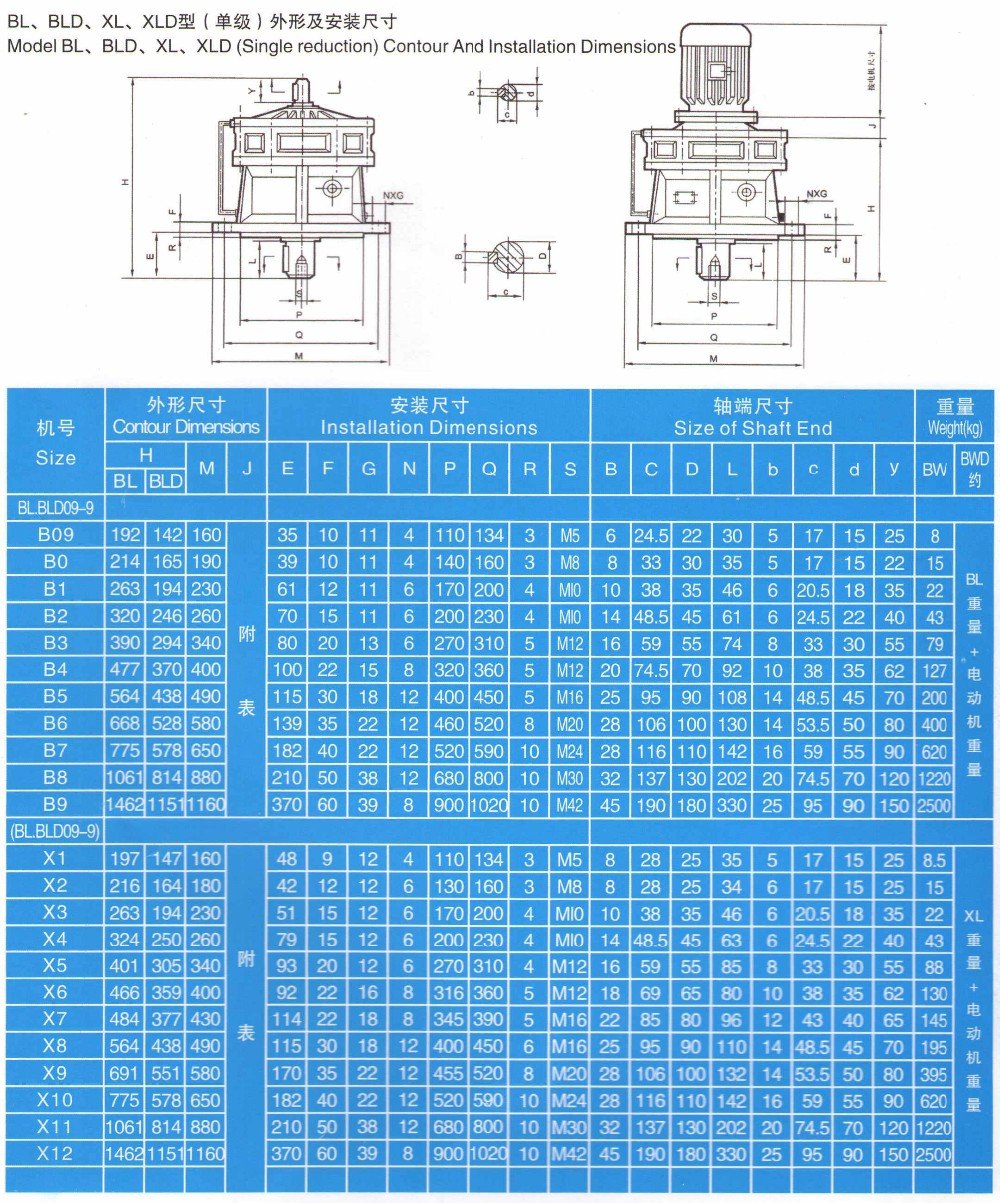

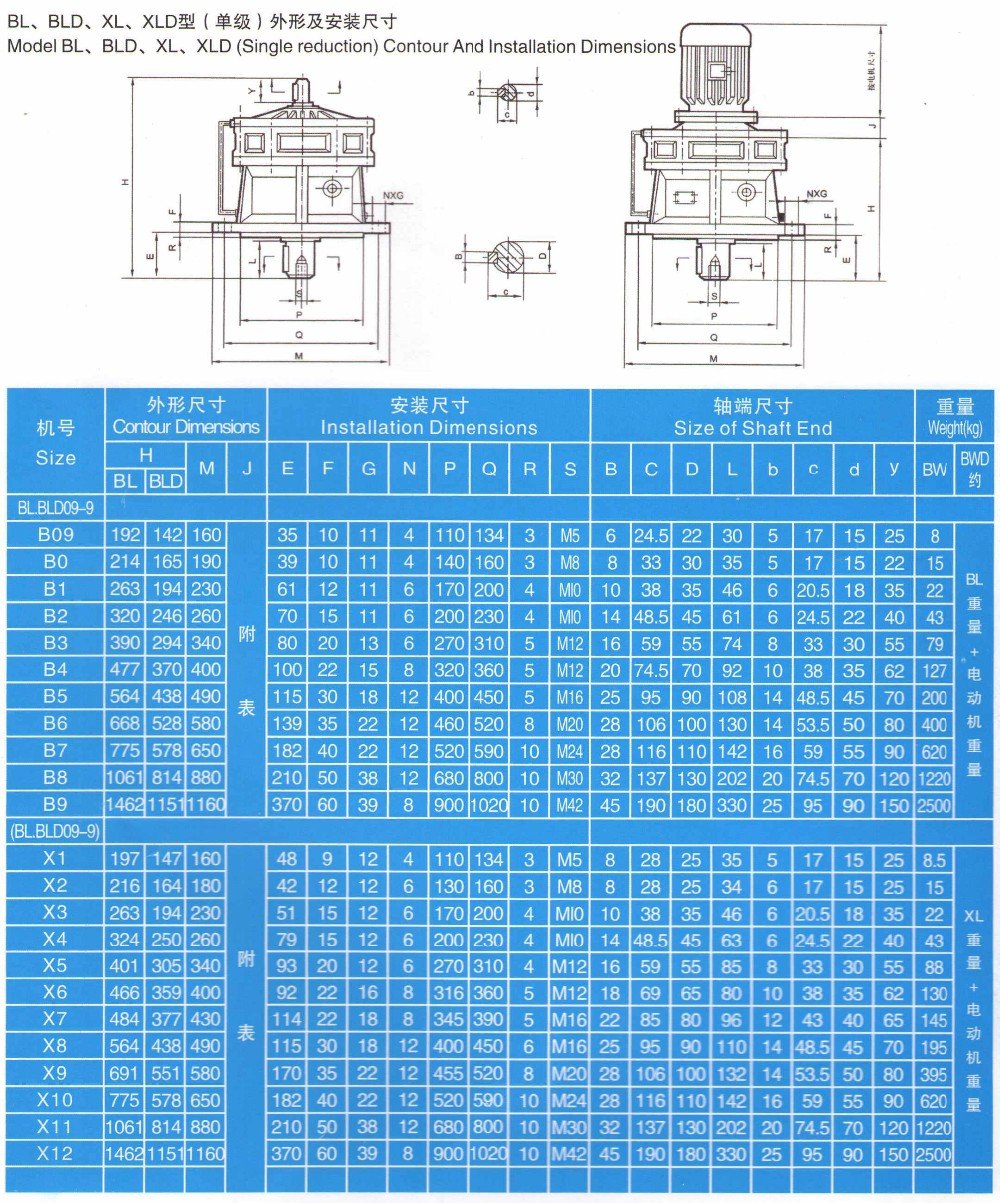

|

Type |

stage |

Model |

Ratio |

Nominal Power (KW) |

Nominal Torque(N.m) |

|

X/B Series Cycloidal Reducer |

Single reducer |

B09/X1 |

9-87 |

0.55-0.18 |

26-50 |

|

B0/X2 |

1.1-0.18 |

58-112 |

|||

|

B1/X3 |

0.55-0.18 |

117-230 |

|||

|

B2/X4 |

4-0.55 |

210-400 |

|||

|

B3/X5 |

11-0.55 |

580-1010 |

|||

|

B4/X6/X7 |

11-2.2 |

580-1670 |

|||

|

B5/X8 |

18.5-2.2 |

1191-3075 |

|||

|

B6/X9 |

15-5.5 |

5183-5605 |

|||

|

B7/X10 |

11-45 |

7643 |

|

Type |

stage |

Model |

Ratio |

Nominal Power (KW) |

Nominal Torque(N.m) |

|

X/B Series Cycloidal reducer |

Double reducer |

B10/X32 |

99-7569 |

0.37-0.18 |

175 |

|

B20/X42 |

1.1-0.18 |

600 |

|||

|

B31/X53 |

2.2-0.25 |

1250 |

|||

|

B41/X63 |

2.2-0.25 |

1179-2500 |

|||

|

B42/X64 |

4-0.55 |

2143-2500 |

|||

|

B52/X84 |

4-0.55 |

2143-5000 |

|||

|

B53/X85 |

7.5-0.55 |

5000 |

|||

|

B63/X95 |

7.5-0.55 |

5893-8820 |

|||

|

B74/X106 |

11-2.2 |

11132-12000 |

|||

|

B84/X117 |

11-2.2 |

11132-16000 |

Main Features

All planetary cycloidal reducer rotating device can be divided into three parts:input part,deceleration part and output part.

Dislocation on the input shaft is equipped with a 180℃ of double eccentric sleeve,equipped with two ball bearings on the eccentric sleeve,the formation of H two cycloid gear center hole is the eccentric sleeve on the turning arm bearing raceway,and by a groud of cycloid gear and pin gear ring of gear meshing,less bad tooth meshing reduction mechanism to form,(in order to reduce friction,in small ratio of speed reducer,the needle with needle teeth on the gear set).

When the input shaft with eccentric sleeve rotation for a week,as a result of the cycloid gear tooth profile curve characteristics and restricted by needle on the gear teeth,the movement of the cycloid gear becoming both revolution and rotation of the plane movement,and input shaft are

made for a week,eccentric sleeve also turn the week,cycloid gear in the opposite direction around a big tooth difference reduction is obtained, then with the help pf W output mechanism,the cycloid gear rotates at low speed movement through the pin shaft,passed to the output shaft,low output speed can be achieved.

Characteristics:

1.Cycloid reducer big reduction ratio, high efficiency: a reduction gear ratio is 9~87, the two-stage reduction gear ratio is 121 ~ 5133, multistage combination can reach tens of thousands, and the needle tooth meshing line type rolling friction, the meshing surface no relative sliding, so a reduction efficiency of 94%.

2.Pin wheel reducer smooth running, low noise: the teeth contact at the same time when in operation, the coincidence degree high, stable running, strong overload capacity, low vibration and noise, a variety of models, small noise.

3. The use of reliable, long life: because the main part is made of high carbon alloy steel quenching (HRC58-62), and then grinding, and cycloid gear and pin gear set mesh transfer to the pin gear form rolling friction pair, friction coefficient is small, so that the meshing zone no relative sliding, wear small, so durable.

4. Compact structure, small volume: compared with other reducer with the power of the above weight, small volume 1/3, as is the planetary transmission, the input shaft and the output shaft in the same axis, in order to obtain the smallest possible size.

Our Company

HangZhouYinxin Electromechanical Facilities Co. Ltd

HangZhouYinxin Electromechanical Equipment Co., Ltd.is a gift enterprise integrating development, design, production and sales,Main promoting products include reducer motor,water pump,construction machinery and parts,bearings,hardware and electrical equipment,plastic products,Labour protection appliance.Our company always follow the operation concept which contains people-oriented, innovation as the soul,be prepared for danger in times of peace, unremitting……

Application area

Certifications

Sales territory

Packing & Delivery

|

Packaging |

|

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

Weight |

1.2 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

|

Packaging |

|

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

Weight |

1.2 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

FAQ

Q1: Are you trading company or manufacturer ?

A: We are a manufacturer in ZJ China.welcome to our factory to have a visit.

Q2: How we select models and specifications?

A:You can email us the series name & code (for example: WJ series worm gearbox) as well as requirement details, such as motor power, output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings, it is better.

Q3: How is your price? Can you offer any discount?

A: We will give the best price we can base on your needs and the quantities.

Q4: How long should I wait for the feedback after I send the enquiry?

A: Within 12 hours.

Q5: What is your product warranty period?

Our factory has obtained the certificate of China’s Farm Machinery Products Quality Authentication promulgated by the Farm Machinery Products Quality Authentication Centre of China.

A:We offer one year warranty since the vessel departure date left China.

Q6: What industries are your gearboxes being used?

A:Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

Best China manufacturer & factory high quality Textile speed reducer reduction ratio 1.5 : 1-100 : 1 worm motor worm gear worm gearbox supplier With high quality best price

our products are selling well in the American, European, South American and Asian markets. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Bearing:

-

Bronze

- Housing Material:

-

Aluminum alloy

- Product name:

-

DEVO NMRV Series gearbox

- Mounting Position:

-

Flange Motunted

- Input Form:

-

Shaft Input

- Output Form:

-

while the types of yokes for the connection of the PTO shafts with the agricultural implement includes the same above splined yokes and also yokes with recessed button and/or ball collar with:

hollow Shaft Output

- Heat treatment:

-

Carburizing & Quenching

- Color:

-

Blue or silver

- Certificate:

-

ISO 9001

- Warranty:

-

Within our field of work is adapting our reducers from the catalogue to our costumer´s necessity by means of flanges, shafts, extensions, supports, etc. according to the necessities of their machines.

1 Year

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 10 >10 Est. Time(days) 15 To be negotiated

Online Customization

EPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting tools.

Product Description

Introductions of NMRV Series Worm Gear Reducer

The NMRV worm gear reducer is equipped with high quality aluminum alloy casting and it adopts the advanced square box structure which is small in size, light in weight and beautiful in apperance. The worm gear reducer could be matched with other gearboxes to reach a large ratio and torque. What’s more, due to the small size of the gearbox, it is easy to install and maintain. The NMRV worm gearboxes are manufactured with international technical requirements and possess a high technological content which guarantee the high rigity and high torque.

Structure Drawing of NMRV Series

|

|

Advantages of NMRV Worm Gearbox |

||||||

|

Low noise |

This worm gearbox is smooth in transmission which is suitable for working in harsh environment for a long time. |

||||||

|

High efficiency |

With the using of tin bronze worm gear material, this worm gear reducer is low in temperature-rising and fast in heat dissipation. |

||||||

|

High quality |

The reducer made of cast iron which casted with Aluminum mould. It`s good looking and solid, and can be used through the setting |

||||||

Parameter Table of NMRV

HIGH QUALITY HOUSING AND BEARING MATERIAL

The reducer is made of cast iron which casted with Aluminum mould. It`s good looking and solid, and can be used through the setting of multi-azimuth

NMRV SERIES WORM GEAR SPEED REDUCER MOUNTING DIMENSIONS

Dimension Diagram of NMRV 50

Profile of Our Company

Our company is located in the city of Xuzhou, ZJ Province of China. We handle the products of power

transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and

other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields:

machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper

industry, cement industry, cableways and so on.

With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the

peers all over the world. We always innovate for the purpose of better meeting the new demands of our customers and

adapting the new tendency of the industry. Depending on the principles of honestly operating and mutual benefit, We

sincerely look forward to cooperating with you.

Application Field

Packing & Delivery

PACKING AND TRANSPORTION

● Packaging: In order to ensure the integrity of product appearance, we will choose cartons, wooden pallets and wooden pallets according to customer needs.

● Delivery time: Each reducer is manufactured and tested in accordance with strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

● Transportation modal: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

● Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

FAQ

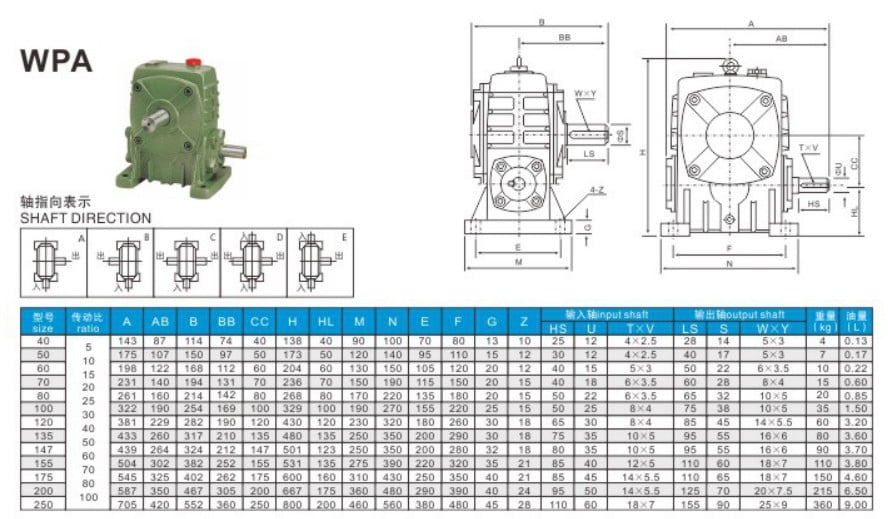

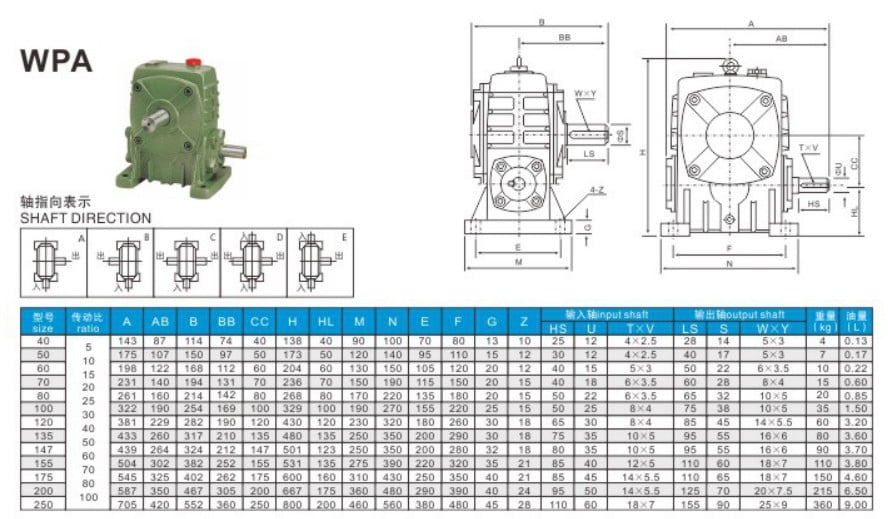

Best China manufacturer & factory High efficiency worm gearbox wpa reducer small gear box gearbox to increase rpm light box reducer transmission With high quality best price

EPG is a professional manufacturer and exporter that is concerned with the design, development and production.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

1.8-2430N.M

- Input Speed:

-

1400rpm

- Output Speed:

-

19-186.7rpm

- Place of Origin:Zhejiang, China

- Accudrive Servo Gearheads Servo drives from EPG Drive benefit from the expertise and innovation of our more traditional brands. Available in both right angle and inline configurations, coupled with the availability of multiple precision levels, you are sure to find the right product for your application.EPG Drive Accudrive Servo Gearhead Brand Name:

-

OEM

- Color:

-

silver, blue, black and so on

- speed ratio:

-

5,10,20,30,40,50,60,70,80,100

- size:

-

40

-

MOQ:

Shear bolt torque limiter (SB) EPG GROUP offers high quality PTO shafts with tubes fixed by spring pin, cross joints with roller bearings with rollers -

1pcs

- other size:

-

please contact Connie Chen

- shaft direction:

-

A,B,C,D,E

Packaging & Delivery

-

Lead Time

: -

Quantity(Boxes) 1 – 1 >1 Est. Time(days) 15 To be negotiated The company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CAD/CAM system, industrial robot etc.

Online Customization

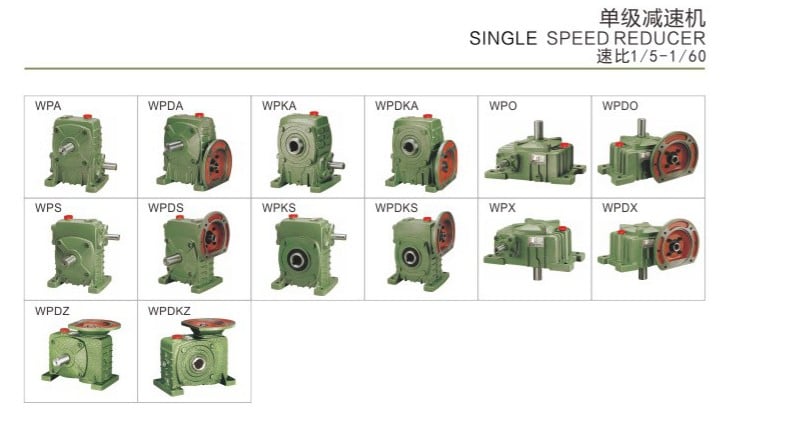

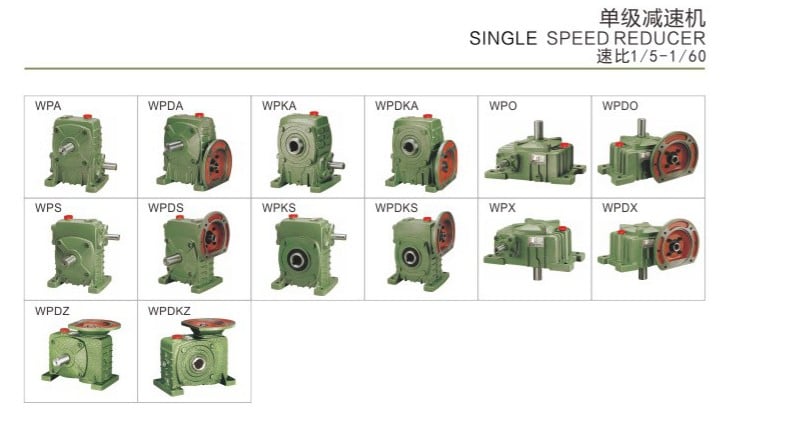

High efficiency worm gearbox wpa reducer small gear box gearbox to increase rpm manchester united light box reducer transmission

Product Description

Main Features

1.Housing:iron cast

2. low noise(<50DB)

3.Model:WPDA 40-250,Ratio:10 to 60

4.Efficient and safe operating

Company Information

Quality control

Our Certifications

Related Product

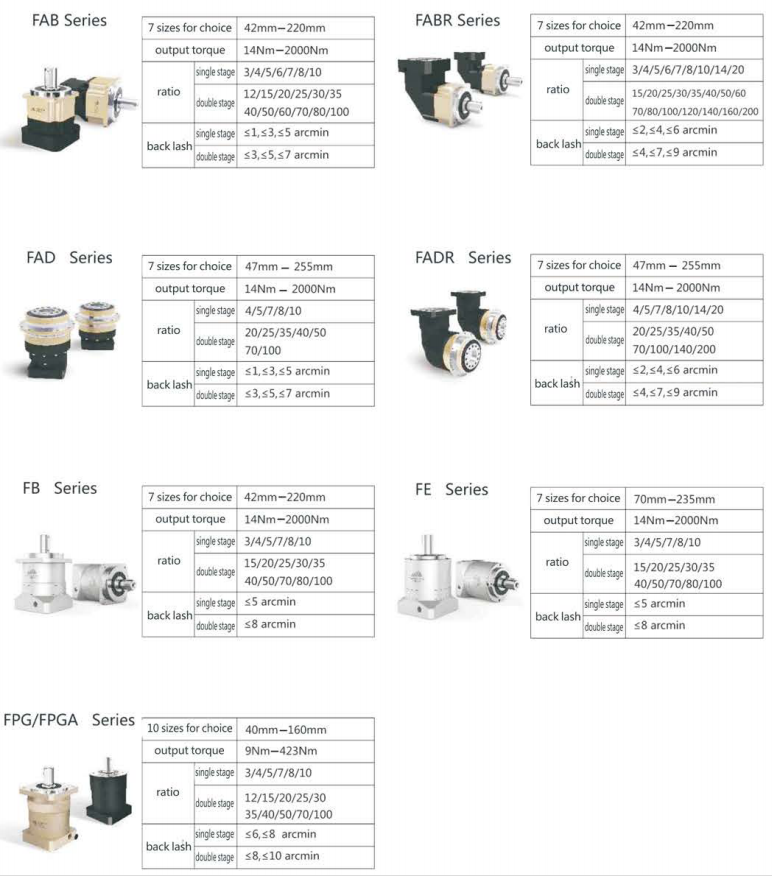

Precision Planetary gearbox

FAQ

1.Payment Term: TT, L/C

2.Delivery time: about 30 days from receive payment.

3.We accept customized products as per your special requirement.

4.Guidelines for the Selection:Usually we can select one machine which is suitable for you with some informations from you,such as ratio/motor speed/mounting dimension/ out torque etc.

5.If the minimum order amount is in excess of $10000, there are preferential.

Q1: What information should I tell you to confirm the product?

A:Model/Size, Transmission Ratio, Shaft directions & Order quantity.

Q2: What can i do if I don’t know which one I need?

A:Dont worry, Send as much information as you can, our team will help you find the right one you are looking for.

Q3: What is your product warranty period?

A:We offer one year warranty since the vessel departure date left China.

Q4: Are you trading company or manufacturer ?

A: We are factory.

Q5: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q6: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q7: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact Us