Product Description

Product Description

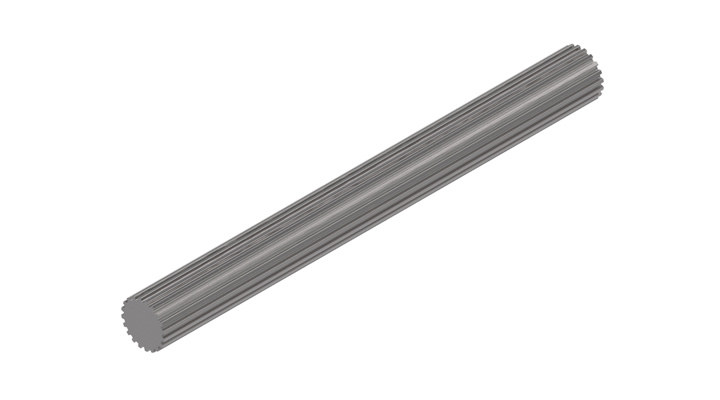

A Power Take-Off shaft (PTO shaft) is a mechanical device utilized to transmit power from a tractor or other power source to an attached implement, such as a mower, tiller, or baler. Typically situated at the rear of the tractor, the PTO shaft is driven by the tractor’s engine through the transmission.

The primary purpose of the PTO shaft is to supply a rotating power source to the implement, enabling it to carry out its intended function. To connect the implement to the PTO shaft, a universal joint is employed, allowing for movement between the tractor and the implement while maintaining a consistent power transfer.

Here is our advantages when compare to similar products from China:

1.Forged yokes make PTO shafts strong enough for usage and working;

2.Internal sizes standard to confirm installation smooth;

3.CE and ISO certificates to guarantee to quality of our goods;

4.Strong and professional package to confirm the good situation when you receive the goods.

Product Specifications

Packaging & Shipping

Company Profile

HangZhou Hanon Technology Co.,ltd is a modern enterprise specilizing in the development,production,sales and services of Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gearpump and motor etc..

We adhere to the principle of ” High Quality, Customers’Satisfaction”, using advanced technology and equipments to ensure all the technical standards of transmission .We follow the principle of people first , trying our best to set up a pleasant surroundings and platform of performance for each employee. So everyone can be self-consciously active to join Hanon Machinery.

FAQ

1.WHAT’S THE PAYMENT TERM?

When we quote for you,we will confirm with you the way of transaction,FOB,CIFetc.<br> For mass production goods, you need to pay 30% deposit before producing and70% balance against copy of documents.The most common way is by T/T.

2.HOW TO DELIVER THE GOODS TO US?

Usually we will ship the goods to you by sea.

3.How long is your delivery time and shipment?

30-45days

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Pto Shaft |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying |

| Material: | 45cr Steel |

| Power Source: | Pto Dirven Shaft |

| Weight: | 8-15kg |

| After-sales Service: | Online Support |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can spline shafts be customized for specific machinery and equipment?

Yes, spline shafts can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation:

1. Size and Length:

Spline shafts can be customized in terms of size and length to fit the dimensions of the machinery or equipment. Manufacturers can design spline shafts with the appropriate diameter, overall length, and spline length to ensure a proper fit within the system.

2. Spline Profile:

The spline profile can be customized based on the specific application. Different spline profiles, such as involute, serrated, or helical, can be used to optimize torque transmission, load distribution, and engagement characteristics based on the requirements of the machinery or equipment.

3. Number of Splines:

The number of splines on the shaft can be customized to match the mating component. The number of splines determines the engagement area and affects the torque-carrying capacity of the spline shaft. By adjusting the number of splines, manufacturers can tailor the spline shaft to the specific torque and load requirements of the machinery or equipment.

4. Material Selection:

The choice of material for spline shafts can be customized based on the operating conditions and environmental factors of the machinery or equipment. Different materials, such as alloy steels or stainless steels, can be selected to provide the necessary strength, durability, corrosion resistance, or other specific properties required for the application.

5. Surface Treatment:

The surface of spline shafts can be customized with various treatments to enhance their performance. Surface treatments like heat treatment, coating, or plating can be applied to improve hardness, wear resistance, or corrosion resistance based on the specific requirements of the machinery or equipment.

6. Tolerances and Fit:

Tolerances and fit between the spline shaft and mating components can be customized to achieve the desired clearance or interference fit. This ensures proper engagement, smooth operation, and optimal performance of the machinery or equipment.

7. Special Features:

In certain cases, spline shafts can be customized with additional features to meet specific needs. This may include the incorporation of keyways, threads, or other specialized features required for the machinery or equipment.

Manufacturers and engineers work closely with the machinery or equipment designers to understand the specific requirements and tailor the spline shafts accordingly. By considering factors such as size, spline profile, number of splines, material selection, surface treatment, tolerances, fit, and any special features, customized spline shafts can be developed to ensure optimal performance and compatibility with the machinery or equipment.

It is important to consult with experienced spline shaft manufacturers or engineering professionals to determine the most suitable customization options for a particular machinery or equipment application.

Can spline shafts be used in automotive applications, and if so, how?

Yes, spline shafts are extensively used in automotive applications due to their ability to transmit torque and provide reliable power transmission. Here’s how spline shafts are used in automotive applications:

Spline shafts play a crucial role in various automotive systems and components, including:

- Drivetrain: Spline shafts are an integral part of the drivetrain system in vehicles. They transmit torque from the engine to the wheels, allowing the vehicle to move. Spline shafts are present in components such as the transmission, differential, and axle shafts. In manual transmissions, the spline shaft connects the transmission input shaft to the clutch disc, enabling power transfer from the engine. In automatic transmissions, spline shafts are used in the torque converter and the output shaft.

- Steering System: Spline shafts are employed in the steering system to transmit torque from the steering wheel to the steering rack or gearbox. They provide a direct connection between the driver’s input and the movement of the wheels, allowing for steering control.

- Power Take-Off (PTO) Systems: Some vehicles, particularly commercial trucks and agricultural machinery, utilize PTO systems. Spline shafts are used in PTOs to transfer power from the vehicle’s engine to auxiliary equipment, such as hydraulic pumps, generators, or agricultural implements.

- Transfer Cases: In four-wheel-drive (4WD) or all-wheel-drive (AWD) vehicles, transfer cases are used to distribute power to the front and rear axles. Spline shafts are utilized in the transfer case to transfer torque between the transmission and the front and rear drive shafts.

- Propeller Shafts: Spline shafts are present in propeller shafts, which transmit torque from the transmission or transfer case to the rear axle in rear-wheel-drive vehicles. They accommodate the relative movement between the transmission and the axle due to suspension travel.

In automotive applications, spline shafts are designed to withstand high torque loads, provide precise torque transmission, and accommodate misalignments and fluctuations in operating conditions. They are typically made from high-strength steel or alloy materials to ensure durability and resistance to wear. Proper lubrication is essential to minimize friction and ensure smooth operation.

The use of spline shafts in automotive applications allows for efficient power transmission, precise control, and reliable performance, contributing to the overall functionality and drivability of vehicles.

What are the advantages of using spline shafts in mechanical systems?

Using spline shafts in mechanical systems offers several advantages. Here’s a detailed explanation:

1. Torque Transmission:

Spline shafts provide efficient torque transmission between the driving and driven components. The interlocking splines ensure a secure and reliable transfer of rotational force, enabling the transmission of power and motion in mechanical systems.

2. Relative Movement Accommodation:

Spline shafts can accommodate relative movement between the driving and driven components. They allow axial, radial, and angular displacements, compensating for misalignments, thermal expansion, and vibrations. This flexibility helps to maintain proper engagement and minimize stress concentrations.

3. Load Distribution:

The splines on the shaft distribute the transmitted load across the entire engagement surface. This helps to reduce localized stresses and prevents premature wear or failure of the components. The load distribution capability of spline shafts contributes to the overall durability and longevity of the mechanical system.

4. Precise Positioning and Control:

Spline shafts enable precise positioning and control of mechanical components. The splines provide accurate rotational alignment, allowing for precise angular positioning and indexing. This is crucial in applications where precise control and synchronization of movements are required.

5. Interchangeability and Standardization:

Spline shafts are available in standardized designs and dimensions. This enables interchangeability between components and facilitates easier maintenance and replacement. Standardization also simplifies the design and manufacturing processes, reducing costs and lead times.

6. High Power Transmission Capacity:

Spline shafts are designed to withstand high torque loads. The interlocking splines provide a large contact area, distributing the transmitted torque across multiple teeth. This allows spline shafts to handle higher power transmission requirements, making them suitable for heavy-duty applications.

7. Versatility:

Spline shafts can be designed and manufactured to suit various application requirements. They can be customized in terms of size, shape, number of splines, and spline profile to match the specific needs of a mechanical system. This versatility makes spline shafts adaptable to a wide range of industries and applications.

8. Reduced Slippage and Backlash:

When properly designed and manufactured, spline shafts exhibit minimal slippage and backlash. The tight fit between the splines prevents significant axial or radial movement during torque transmission, resulting in improved efficiency and precision in mechanical systems.

In summary, the advantages of using spline shafts in mechanical systems include efficient torque transmission, accommodation of relative movement, load distribution, precise positioning and control, interchangeability, high power transmission capacity, versatility, and reduced slippage and backlash. These advantages make spline shafts a reliable and effective choice in various applications where power transfer, flexibility, and precise motion control are essential.

editor by CX 2024-02-21

China Best Sales Agricultural Tractor Combines Cultivator Transmission System Parts Drive Shaft Transmission Slip Yoke

Product Description

1

Products

Name: Agricultural Tractor Combines Cultivator Transmission System Parts Drive Shaft Transmission Slip Yoke

Material: 40Cr

Weight: From .2kg-5kg

Packing: wooden case

Min order: 1000pcs

Customized production is available as your drawings or sample.

| Process | Die Forging | |

| Material | Stainless Steel, Carbon Steel, Alloy Steel | |

| Weight | 0.1Kg~20Kg | |

| Heat Treatment | Quenching, Annealing,Tempering,Normalizing, Quenching and Tempering | |

| Testing instrument | composition testing | Spectrometer, Metallographic microscope |

| Performance testing | Hardness tester, Tensile testing machine | |

| Size Measuring | CMM,Micrometer, Vernier Caliper, Depth Caliper, feeler gauge | |

| Thread Gauge , Height Gauge | ||

| Roughness | Ra1.6~Ra6.3 | |

| Machining Equipment | CNC Center , CNC Machines, Turning, Drilling, Milling, boring machine,Grinding Machines, | |

| Wire EDM,Laser Cutting&Welding, Plasma Cutting &Welding, EDM etc. | ||

| Quality control | Sampling inspection of raw materials and semi-finished products, 100% Inspection of finished products | |

| Surface Treatment | Shot Blast , Powder Coating, Polishing, Galvanized , Chrome Plated | |

| Production Capacity | 60000T / Years | |

| Lead Time | Normally 30 – 45 Days. | |

| Payment Terms | T/T , L/C | |

| Material Standard | ASTM , AISI , DIN , BS, JIS, GB, | |

| Certification | ISO9001:2008, IATF16949:2016 | |

2

Products Quality Control

Quality control involve the inspection and control of incoming materials, production processes, and finished products.

The quality control process includes,

1 First of all, the incoming raw materials with random sampling are analyzed by metallographic microscope to ensure that the chemical composition meets the production requirements

2 Then In the production process, there are QC staffs timely sampling ensure that the products are free of defects in the manufacturing process, and to coordinate and handle any abnormal quality issues may be occurred.

3 The final step of production process is magnetic particle flaw detector of the metal parts to detect it’s hidden crack or other defects.

4 All the finished metal parts is sampled in proportion and sent to the laboratory for various mechanical performance tests and size measurement, and the surface quality is manually 100% inspected.

The relevant testing equipment pictures are as following:

3

Quality Management System Control:

We strictly carry out system management accordance with iso9001 and ts16949 quality standards. And 5S lean production management is implemented on the production site.

The production management site as following:

4

Our Advantages:

Brand

Our parent company, HiHangZhou Group, is a world-renowned high-end machinery manufacturing enterprise with 40 domestic subsidiaries and branches and 8 foreign manufacturing plants. Has long-term experience and good reputation in cooperation with world-renowned enterprises.

Technology

We have a complete production process and equipment research and development capabilities for ferrous metals forming. More than 25 years of production experience in forging equipment and casting equipment manufacturers, make us more thoroughly get all the performance of each equipment. One-third of our company’s employees are technician and R&D personnel, ensuring that high-quality products are produced with high efficiency.

Service

We can provide custom and standard manufacturing services with multiple manufacturing process integrations. The quality and delivery of products can be fully guaranteed, and the ability to communicate quickly and effectively.

Culture

The unique corporate culture can give full play to the potential of individuals and provide a strong vitality for the sustainable development of the company.

Social responsibility

Our company strictly implements low-carbon environmental protection, energy-saving and emission-reduction production, and is a benchmark enterprise in local region.

5

Company Culture

Our Vision

To become 1 of the leading companies

Our Mission

To become a platform for employees to realize their dream

To become 1 of the transforming and upgrading pacemaker of Chinese enterprises

To set the national brands with pride

Our Belief

Strive to build the company into an ideal platform for entrepreneurs to realize their self-worth and contribute to the society

Values

Improvement is innovation, everyone can innovate

innovation inspired and failures tolerated

6

FAQ

1.

Q: Are you a trading company or a manufacturer?

A: Obviously we are a manufacturer of forging products, casting products and also have a high level of machining capabilities.

2.

Q: What series products do your have?

A: We are mainly engaged in forming processing of ferrous metals, including processing by casting , forging and machining. As you know, such machinery parts can be observed in various industries of equipment manufacturing.

3

Q: Do you provide samples? is it free?

A: Yes, we commonly provide samples according to the traditional practice, but we also need customers to provide a freight pay-by-account number to show mutual CHINAMFG of cooperation.

4

Q: Is OEM available?

A: Yes, OEM is available.

5

Q: What’s your quality guarantee?

A: We insist that the survival of the company should depend on the products quality continuous improvement, without which we cannot survive for long. We carry out strictly product quality control for every process from incoming materials, production process to finished products via advanced detection instrument and equipment. We also invite independent third parties to certify our quality and management systems. Till now we have passed ISO/TS16949 and SGS certification .

6

Q. How about the Packing?

A: We usually use the iron box, or wooden case, also it can be customized according to customer’s demands.

7

Q: What is your minimum order quantity?

A: Yes, we require all international orders to have an minimum order quantity. The quantity is up to the exact products feature or property such as the material, weight, construction etc.

8

Q: What is the lead time?

A: Generally our forging products and casting products need to make new dies or molds, the time of making new dies or molds and samples within 30-45 days, and the large batch production time within 30-45 days. it’s also according to the parts structural complexity and quantity.

9

Q: What kinds of payment methods do you accept?

A: You can make the payment by T/T or L/C. 30% deposit in advance, 70% balance against the copy of B/L.

Certification

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Processing Object: | Metal |

|---|---|

| Molding Style: | Forging |

| Molding Technics: | Pressure Casting |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do spline shafts contribute to efficient power transmission?

Spline shafts play a vital role in enabling efficient power transmission in various mechanical systems. Here’s a detailed explanation of how spline shafts contribute to efficient power transmission:

1. Torque Transmission:

Spline shafts are designed to transmit torque from one component to another. They provide a positive, non-slip connection that allows for efficient power transfer without slippage or loss of energy. The splines on the shaft engage with corresponding splines on the mating component, creating a strong mechanical connection for torque transmission.

2. Load Distribution:

Spline shafts distribute the applied load evenly across the engagement surfaces. The teeth or grooves on the shaft’s spline profile ensure that the load is shared across multiple contact points. This even load distribution helps prevent localized stress concentrations and reduces the risk of premature wear or failure. Efficient load distribution ensures that power is transmitted smoothly and reliably.

3. Misalignment Compensation:

Spline shafts can accommodate a certain degree of misalignment between the mating components. The spline profile design allows for angular or parallel misalignment without compromising the power transmission capability. This misalignment compensation capability is crucial in maintaining efficient power transmission in situations where perfect alignment is challenging or subject to variations.

4. High Torque Capacity:

Spline shafts are designed to withstand high torque levels. The spline profile, engagement length, and material selection are optimized to handle the expected torque requirements. This high torque capacity ensures that the shaft can efficiently transmit power without experiencing excessive deflection or failure under normal operating conditions.

5. Torsional Stiffness:

Spline shafts exhibit high torsional stiffness, which means they resist twisting or torsional deflection when subjected to torque. The shaft’s design, including its diameter, spline profile, and material properties, contributes to its torsional stiffness. High torsional stiffness minimizes power loss due to deformation or flexing of the shaft, allowing for efficient power transmission.

6. Reliable Connection:

Spline shafts provide a reliable and repeatable connection between the driving and driven components. Once properly engaged, the spline shaft maintains its connection, ensuring consistent power transmission over time. This reliability is crucial in maintaining efficiency and preventing power loss or interruptions during operation.

7. Minimal Backlash:

Backlash refers to the slight rotational play or clearance between mating components. Spline shafts, when properly designed and manufactured, can minimize backlash in the power transmission system. Reduced backlash ensures smoother operation, improved accuracy, and efficiency by minimizing power losses associated with reversing or changing direction.

8. Compact Design:

Spline shafts offer a compact and space-efficient solution for power transmission. Their design allows for a relatively small footprint while providing robust torque transmission capabilities. The compact design is particularly advantageous in applications where space is limited, such as automotive drivetrains or compact machinery.

By incorporating spline shafts into mechanical systems, engineers can achieve efficient power transmission, ensuring that power is effectively transferred from the driving source to the driven components. The unique design features of spline shafts enable reliable torque transmission, even load distribution, misalignment compensation, high torque capacity, torsional stiffness, reliable connections, minimal backlash, and compactness.

Can spline shafts be repaired or maintained when necessary?

Yes, spline shafts can be repaired and maintained when necessary to ensure their continued functionality and performance. Here are some ways spline shafts can be repaired and maintained:

1. Inspection and Assessment:

When an issue is suspected with a spline shaft, the first step is to conduct a thorough inspection. This involves examining the shaft for any signs of wear, damage, or misalignment. Special attention is given to the spline teeth, which may show signs of wear or deformation. Through inspection and assessment, the extent of the repair or maintenance required can be determined.

2. Spline Tooth Repair:

If the spline teeth are damaged or worn, they can be repaired or replaced. Repair methods may include re-machining the teeth to restore their original profile, filling and reshaping the worn areas using specialized welding techniques, or replacing the damaged section of the spline shaft. The specific repair method depends on the severity of the damage and the material of the spline shaft.

3. Lubrication and Cleaning:

Regular lubrication and cleaning are essential for maintaining spline shafts. Lubricants help reduce friction and wear between the mating surfaces, while cleaning removes contaminants that can affect the spline’s engagement. During maintenance, old lubricants are removed, and fresh lubricants are applied to ensure smooth operation and prevent premature failure.

4. Surface Treatment:

If the spline shaft undergoes wear or corrosion, surface treatment can be applied to restore its condition. This may involve applying coatings or treatments to enhance the hardness, wear resistance, or corrosion resistance of the spline shaft. Surface treatments can improve the longevity and performance of the spline shaft, reducing the need for frequent repairs.

5. Balancing and Alignment:

If a spline shaft is experiencing vibration or misalignment issues, it may require balancing or realignment. Balancing involves redistributing mass along the shaft to minimize vibrations, while alignment ensures proper mating and engagement with other components. Balancing and alignment procedures help optimize the performance and longevity of the spline shaft.

6. Replacement:

In cases where the spline shaft is severely damaged or worn beyond repair, replacement may be necessary. Replacement spline shafts can be sourced from manufacturers or specialized suppliers who can provide shafts that meet the required specifications and tolerances.

It’s important to note that the repair and maintenance of spline shafts should be carried out by qualified professionals with expertise in precision machining and mechanical systems. They have the knowledge and tools to properly assess, repair, or replace spline shafts, ensuring the integrity and functionality of the system in which they are used.

By implementing regular maintenance and timely repairs, spline shafts can be kept in optimal condition, extending their lifespan and maintaining their performance in various mechanical applications.

What are the advantages of using spline shafts in mechanical systems?

Using spline shafts in mechanical systems offers several advantages. Here’s a detailed explanation:

1. Torque Transmission:

Spline shafts provide efficient torque transmission between the driving and driven components. The interlocking splines ensure a secure and reliable transfer of rotational force, enabling the transmission of power and motion in mechanical systems.

2. Relative Movement Accommodation:

Spline shafts can accommodate relative movement between the driving and driven components. They allow axial, radial, and angular displacements, compensating for misalignments, thermal expansion, and vibrations. This flexibility helps to maintain proper engagement and minimize stress concentrations.

3. Load Distribution:

The splines on the shaft distribute the transmitted load across the entire engagement surface. This helps to reduce localized stresses and prevents premature wear or failure of the components. The load distribution capability of spline shafts contributes to the overall durability and longevity of the mechanical system.

4. Precise Positioning and Control:

Spline shafts enable precise positioning and control of mechanical components. The splines provide accurate rotational alignment, allowing for precise angular positioning and indexing. This is crucial in applications where precise control and synchronization of movements are required.

5. Interchangeability and Standardization:

Spline shafts are available in standardized designs and dimensions. This enables interchangeability between components and facilitates easier maintenance and replacement. Standardization also simplifies the design and manufacturing processes, reducing costs and lead times.

6. High Power Transmission Capacity:

Spline shafts are designed to withstand high torque loads. The interlocking splines provide a large contact area, distributing the transmitted torque across multiple teeth. This allows spline shafts to handle higher power transmission requirements, making them suitable for heavy-duty applications.

7. Versatility:

Spline shafts can be designed and manufactured to suit various application requirements. They can be customized in terms of size, shape, number of splines, and spline profile to match the specific needs of a mechanical system. This versatility makes spline shafts adaptable to a wide range of industries and applications.

8. Reduced Slippage and Backlash:

When properly designed and manufactured, spline shafts exhibit minimal slippage and backlash. The tight fit between the splines prevents significant axial or radial movement during torque transmission, resulting in improved efficiency and precision in mechanical systems.

In summary, the advantages of using spline shafts in mechanical systems include efficient torque transmission, accommodation of relative movement, load distribution, precise positioning and control, interchangeability, high power transmission capacity, versatility, and reduced slippage and backlash. These advantages make spline shafts a reliable and effective choice in various applications where power transfer, flexibility, and precise motion control are essential.

editor by CX 2024-02-13

China Best Sales Pto Shaft Heavy Duty Agriculture Agricoles Wide Angle Post Hole Digger Mower Spline Tractor Shaft Flexible Pto Drive Shaft drive shaft coupling

Product Description

Product Description

| Materlal and Surface Treatment | |

| Cross shaft | Heat treatment of 20Cr2Ni4A forging |

| Bearing cup | 20CrMOTi forging heat treatment |

| Flange fork | ZG35CrMo steel casting |

| Spline shaft | 42GrMo forging heat treatment |

| Spline bushing | 35CrM0 forging heat treatment |

| Sleeve body | 42CrMo forging |

| Surface treatment | spraying |

| Flat key, positioning ring | 42GrMo forging |

In 2571, HangZhou CZPT Machinery Co.,ltd was established by Ms. Iris and her 2 partners(Mr. Tian and Mr. Yang) in HangZhou city(ZHangZhoug province, China), all 3 Founders are engineers who have more than averaged 30 years of experience. Then because the requirements of business expansion, in 2014, it moved to the current Xihu (West Lake) Dis. Industrial Zone (HangZhou city, ZHangZhoug province, China).

Through our CZPT brand ND, CZPT Machinery delivers agricultural solutions to agriculture machinery manufacturer and distributors CZPT through a full line of spiral bevel gearboxes, straight bevel gearboxes, spur gearboxes, drive shafts, sheet metal, hydraulic cylinder, motors, tyre, worm gearboxes, worm operators etc. Products can be customized as request.

We, CZPT machinery established a complete quality management system and sales service network to provide clients with high-quality products and satisfactory service. Our products are sold in 40 provinces and municipalities in China and 36 countries and regions in the world, our main market is the European market.

Certifications

Why choose us?

1) Customization: With a strong R&D team, and we can develop products as required. It only takes up to 7 days for us to design a set of drawings. The production time for new products is usually 50 days or less.

2) Quality: We have our own complete inspection and testing equipment, which can ensure the quality of the products.

3) Capacity: Our annual production capacity is over 500,000 sets, also, we also accept small quantity orders, to meet the needs of different customer’s purchase quantities.

4) Service: We focus on offering high-quality products. Our products are in line with international standards and are mainly exported to Europe, Australia, and other countries and regions.

5) Shipment: We are close to HangZhou and ZheJiang ports, to provide the fastest shipping service.

FAQ

Q: Are you a trading company or manufacturer?

A: We’re factory and providing gearbox ODM & OEM services for the European market for more than 10 years

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time? What is your terms of payment?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization.

For standard products, the payment is: 30% T/T in advance,balance before shipment.

Q: What is the exact MOQ or price for your product?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.

Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

| After-sales Service: | Provided |

|---|---|

| Condition: | New |

| Color: | Red, Silver, Yellow, Black |

| Certification: | CE, ISO, BV |

| Type: | Universal Joint |

| Application Brand: | Agricultural Machine |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Types of Splines

There are four types of splines: Involute, Parallel key, helical, and ball. Learn about their characteristics. And, if you’re not sure what they are, you can always request a quotation. These splines are commonly used for building special machinery, repair jobs, and other applications. The CZPT Manufacturing Company manufactures these shafts. It is a specialty manufacturer and we welcome your business.

Involute splines

The involute spline provides a more rigid and durable structure, and is available in a variety of diameters and spline counts. Generally, steel, carbon steel, or titanium are used as raw materials. Other materials, such as carbon fiber, may be suitable. However, titanium can be difficult to produce, so some manufacturers make splines using other constituents.

When splines are used in shafts, they prevent parts from separating during operation. These features make them an ideal choice for securing mechanical assemblies. Splines with inward-curving grooves do not have sharp corners and are therefore less likely to break or separate while they are in operation. These properties help them to withstand high-speed operations, such as braking, accelerating, and reversing.

A male spline is fitted with an externally-oriented face, and a female spline is inserted through the center. The teeth of the male spline typically have chamfered tips to provide clearance with the transition area. The radii and width of the teeth of a male spline are typically larger than those of a female spline. These specifications are specified in ANSI or DIN design manuals.

The effective tooth thickness of a spline depends on the involute profile error and the lead error. Also, the spacing of the spline teeth and keyways can affect the effective tooth thickness. Involute splines in a splined shaft are designed so that at least 25 percent of the spline teeth engage during coupling, which results in a uniform distribution of load and wear on the spline.

Parallel key splines

A parallel splined shaft has a helix of equal-sized grooves around its circumference. These grooves are generally parallel or involute. Splines minimize stress concentrations in stationary joints and allow linear and rotary motion. Splines may be cut or cold-rolled. Cold-rolled splines have more strength than cut spines and are often used in applications that require high strength, accuracy, and a smooth surface.

A parallel key splined shaft features grooves and keys that are parallel to the axis of the shaft. This design is best suited for applications where load bearing is a primary concern and a smooth motion is needed. A parallel key splined shaft can be made from alloy steels, which are iron-based alloys that may also contain chromium, nickel, molybdenum, copper, or other alloying materials.

A splined shaft can be used to transmit torque and provide anti-rotation when operating as a linear guide. These shafts have square profiles that match up with grooves in a mating piece and transmit torque and rotation. They can also be easily changed in length, and are commonly used in aerospace. Its reliability and fatigue life make it an excellent choice for many applications.

The main difference between a parallel key splined shaft and a keyed shaft is that the former offers more flexibility. They lack slots, which reduce torque-transmitting capacity. Splines offer equal load distribution along the gear teeth, which translates into a longer fatigue life for the shaft. In agricultural applications, shaft life is essential. Agricultural equipment, for example, requires the ability to function at high speeds for extended periods of time.

Involute helical splines

Involute splines are a common design for splined shafts. They are the most commonly used type of splined shaft and feature equal spacing among their teeth. The teeth of this design are also shorter than those of the parallel spline shaft, reducing stress concentration. These splines can be used to transmit power to floating or permanently fixed gears, and reduce stress concentrations in the stationary joint. Involute splines are the most common type of splined shaft, and are widely used for a variety of applications in automotive, machine tools, and more.

Involute helical spline shafts are ideal for applications involving axial motion and rotation. They allow for face coupling engagement and disengagement. This design also allows for a larger diameter than a parallel spline shaft. The result is a highly efficient gearbox. Besides being durable, splines can also be used for other applications involving torque and energy transfer.

A new statistical model can be used to determine the number of teeth that engage for a given load. These splines are characterized by a tight fit at the major diameters, thereby transferring concentricity from the shaft to the female spline. A male spline has chamfered tips for clearance with the transition area. ANSI and DIN design manuals specify the different classes of fit.

The design of involute helical splines is similar to that of gears, and their ridges or teeth are matched with the corresponding grooves in a mating piece. It enables torque and rotation to be transferred to a mate piece while maintaining alignment of the two components. Different types of splines are used in different applications. Different splines can have different levels of tooth height.

Involute ball splines

When splines are used, they allow the shaft and hub to engage evenly over the shaft’s entire circumference. Because the teeth are evenly spaced, the load that they can transfer is uniform and their position is always the same regardless of shaft length. Whether the shaft is used to transmit torque or to transmit power, splines are a great choice. They provide maximum strength and allow for linear or rotary motion.

There are three basic types of splines: helical, crown, and ball. Crown splines feature equally spaced grooves. Crown splines feature involute sides and parallel sides. Helical splines use involute teeth and are often used in small diameter shafts. Ball splines contain a ball bearing inside the splined shaft to facilitate rotary motion and minimize stress concentration in stationary joints.

The two types of splines are classified under the ANSI classes of fit. Fillet root splines have teeth that mesh along the longitudinal axis of rotation. Flat root splines have similar teeth, but are intended to optimize strength for short-term use. Both types of splines are important for ensuring the shaft aligns properly and is not misaligned.

The friction coefficient of the hub is a complex process. When the hub is off-center, the center moves in predictable but irregular motion. Moreover, when the shaft is centered, the center may oscillate between being centered and being off-center. To compensate for this, the torque must be adequate to keep the shaft in its axis during all rotation angles. While straight-sided splines provide similar centering, they have lower misalignment load factors.

Keyed shafts

Essentially, splined shafts have teeth or ridges that fit together to transfer torque. Because splines are not as tall as involute gears, they offer uniform torque transfer. Additionally, they provide the opportunity for torque and rotational changes and improve wear resistance. In addition to their durability, splined shafts are popular in the aerospace industry and provide increased reliability and fatigue life.

Keyed shafts are available in different materials, lengths, and diameters. When used in high-power drive applications, they offer higher torque and rotational speeds. The higher torque they produce helps them deliver power to the gearbox. However, they are not as durable as splined shafts, which is why the latter is usually preferred in these applications. And while they’re more expensive, they’re equally effective when it comes to torque delivery.

Parallel keyed shafts have separate profiles and ridges and are used in applications requiring accuracy and precision. Keyed shafts with rolled splines are 35% stronger than cut splines and are used where precision is essential. These splines also have a smooth finish, which can make them a good choice for precision applications. They also work well with gears and other mechanical systems that require accurate torque transfer.

Carbon steel is another material used for splined shafts. Carbon steel is known for its malleability, and its shallow carbon content helps create reliable motion. However, if you’re looking for something more durable, consider ferrous steel. This type contains metals such as nickel, chromium, and molybdenum. And it’s important to remember that carbon steel is not the only material to consider.

editor by CX 2023-05-12

China Agricultural Wide Angle Cardan Kubota Spline Cross Yoke Adapter Universal Joint Cover Rotavator Tractor Drive bush hog PTO Shaft with Best Sales

Situation: New

Warranty: 1.5 years

Relevant Industries: Manufacturing Plant, Equipment Restore Retailers, Foodstuff & Beverage Manufacturing unit, Farms, House Use, Design works , Power & Mining

Weight (KG): ten KG

Showroom Spot: Italy

Online video outgoing-inspection: Supplied

Equipment Take a look at Report: Provided

Marketing and advertising Sort: New Solution 2571

Sort: Shafts

Use: Tractors

certification: CE

Material: Steel

Shade: Yellow&Black

Processing of yoke: Forging

Processing of tube: Cold drawn

Style: Custom-made

Certificate: CE Certification

After Warranty Services: On the internet assist

Packaging Details: carton/iron crate

Port: HangZhou or ZheJiang

Products Description Rewards of our group 1. Specializing in production and offering the farm device far more than eleven many years.2. “CE certificate”3. With the rigid quality manage and greatest services for clients.4.We can provide exceptional and speedy right after-revenue support.5. Our purpose: earn-earn.6. We can layout and generate devices in accordance to customer’s requirements.

| Function of PTO Shaft | Drive Shaft Elements & Energy Transmission |

| Usage of PTO Shaft | Kinds of Tractors & Farm Implements |

| Yoke Kinds for PTO Shaft | Double drive pin, Bolt pins, NMRV090 gearbox with single-period motor 70rpm ratio20 Break up pins, Pushpin, Rapid release, Ball attachment, Collar….. |

| Processing Of Yoke | Forging |

| PTO Shaft Plastic Go over | YW BW YS BS And so on |

| Colors of PTO Shaft | Green Orange Yellow Black Ect. |

| PTO Shaft Series | T1-T10 2571 Sizzling marketing quad 250cc 4×4 off road farm ATV All-terrain ATV 4×4 grown ups farm cars atv L1-L6S6-S1010HP-150HP with SA,RA,SB,SFF,WA,CV And so forth |

| Tube Varieties for PTO Shaft | Lemon, Triangular, Star, Sq., Hexangular, Spline, Titanium Engine Stud Button Sprocket Unf M5 M12 Hexagonal Socket M5 X 20Mm Titanium Bottle Cage Capped Bolt Titanium Motorbike Particular Ect |

| Processing Of Tube | Cold drawn |

| Spline Varieties for PTO Shaft | 1 1/8″ Z61 3/8″ Z6 1 3/8″ Z21 1 3/4″ Z20 1 3/4″ Z6 8-38*32*6 8-forty two*36*7 8-forty eight*forty two*8 |

How to Calculate Stiffness, Centering Force, Wear and Fatigue Failure of Spline Couplings

There are various types of spline couplings. These couplings have several important properties. These properties are: Stiffness, Involute splines, Misalignment, Wear and fatigue failure. To understand how these characteristics relate to spline couplings, read this article. It will give you the necessary knowledge to determine which type of coupling best suits your needs. Keeping in mind that spline couplings are usually spherical in shape, they are made of steel.

Involute splines

An effective side interference condition minimizes gear misalignment. When two splines are coupled with no spline misalignment, the maximum tensile root stress shifts to the left by five mm. A linear lead variation, which results from multiple connections along the length of the spline contact, increases the effective clearance or interference by a given percentage. This type of misalignment is undesirable for coupling high-speed equipment.

Involute splines are often used in gearboxes. These splines transmit high torque, and are better able to distribute load among multiple teeth throughout the coupling circumference. The involute profile and lead errors are related to the spacing between spline teeth and keyways. For coupling applications, industry practices use splines with 25 to fifty-percent of spline teeth engaged. This load distribution is more uniform than that of conventional single-key couplings.

To determine the optimal tooth engagement for an involved spline coupling, Xiangzhen Xue and colleagues used a computer model to simulate the stress applied to the splines. The results from this study showed that a “permissible” Ruiz parameter should be used in coupling. By predicting the amount of wear and tear on a crowned spline, the researchers could accurately predict how much damage the components will sustain during the coupling process.

There are several ways to determine the optimal pressure angle for an involute spline. Involute splines are commonly measured using a pressure angle of 30 degrees. Similar to gears, involute splines are typically tested through a measurement over pins. This involves inserting specific-sized wires between gear teeth and measuring the distance between them. This method can tell whether the gear has a proper tooth profile.

The spline system shown in Figure 1 illustrates a vibration model. This simulation allows the user to understand how involute splines are used in coupling. The vibration model shows four concentrated mass blocks that represent the prime mover, the internal spline, and the load. It is important to note that the meshing deformation function represents the forces acting on these three components.

Stiffness of coupling

The calculation of stiffness of a spline coupling involves the measurement of its tooth engagement. In the following, we analyze the stiffness of a spline coupling with various types of teeth using two different methods. Direct inversion and blockwise inversion both reduce CPU time for stiffness calculation. However, they require evaluation submatrices. Here, we discuss the differences between these two methods.

The analytical model for spline couplings is derived in the second section. In the third section, the calculation process is explained in detail. We then validate this model against the FE method. Finally, we discuss the influence of stiffness nonlinearity on the rotor dynamics. Finally, we discuss the advantages and disadvantages of each method. We present a simple yet effective method for estimating the lateral stiffness of spline couplings.

The numerical calculation of the spline coupling is based on the semi-analytical spline load distribution model. This method involves refined contact grids and updating the compliance matrix at each iteration. Hence, it consumes significant computational time. Further, it is difficult to apply this method to the dynamic analysis of a rotor. This method has its own limitations and should be used only when the spline coupling is fully investigated.

The meshing force is the force generated by a misaligned spline coupling. It is related to the spline thickness and the transmitting torque of the rotor. The meshing force is also related to the dynamic vibration displacement. The result obtained from the meshing force analysis is given in Figures 7, 8, and 9.

The analysis presented in this paper aims to investigate the stiffness of spline couplings with a misaligned spline. Although the results of previous studies were accurate, some issues remained. For example, the misalignment of the spline may cause contact damages. The aim of this article is to investigate the problems associated with misaligned spline couplings and propose an analytical approach for estimating the contact pressure in a spline connection. We also compare our results to those obtained by pure numerical approaches.

Misalignment

To determine the centering force, the effective pressure angle must be known. Using the effective pressure angle, the centering force is calculated based on the maximum axial and radial loads and updated Dudley misalignment factors. The centering force is the maximum axial force that can be transmitted by friction. Several published misalignment factors are also included in the calculation. A new method is presented in this paper that considers the cam effect in the normal force.

In this new method, the stiffness along the spline joint can be integrated to obtain a global stiffness that is applicable to torsional vibration analysis. The stiffness of bearings can also be calculated at given levels of misalignment, allowing for accurate estimation of bearing dimensions. It is advisable to check the stiffness of bearings at all times to ensure that they are properly sized and aligned.

A misalignment in a spline coupling can result in wear or even failure. This is caused by an incorrectly aligned pitch profile. This problem is often overlooked, as the teeth are in contact throughout the involute profile. This causes the load to not be evenly distributed along the contact line. Consequently, it is important to consider the effect of misalignment on the contact force on the teeth of the spline coupling.

The centre of the male spline in Figure 2 is superposed on the female spline. The alignment meshing distances are also identical. Hence, the meshing force curves will change according to the dynamic vibration displacement. It is necessary to know the parameters of a spline coupling before implementing it. In this paper, the model for misalignment is presented for spline couplings and the related parameters.

Using a self-made spline coupling test rig, the effects of misalignment on a spline coupling are studied. In contrast to the typical spline coupling, misalignment in a spline coupling causes fretting wear at a specific position on the tooth surface. This is a leading cause of failure in these types of couplings.

Wear and fatigue failure

The failure of a spline coupling due to wear and fatigue is determined by the first occurrence of tooth wear and shaft misalignment. Standard design methods do not account for wear damage and assess the fatigue life with big approximations. Experimental investigations have been conducted to assess wear and fatigue damage in spline couplings. The tests were conducted on a dedicated test rig and special device connected to a standard fatigue machine. The working parameters such as torque, misalignment angle, and axial distance have been varied in order to measure fatigue damage. Over dimensioning has also been assessed.

During fatigue and wear, mechanical sliding takes place between the external and internal splines and results in catastrophic failure. The lack of literature on the wear and fatigue of spline couplings in aero-engines may be due to the lack of data on the coupling’s application. Wear and fatigue failure in splines depends on a number of factors, including the material pair, geometry, and lubrication conditions.

The analysis of spline couplings shows that over-dimensioning is common and leads to different damages in the system. Some of the major damages are wear, fretting, corrosion, and teeth fatigue. Noise problems have also been observed in industrial settings. However, it is difficult to evaluate the contact behavior of spline couplings, and numerical simulations are often hampered by the use of specific codes and the boundary element method.

The failure of a spline gear coupling was caused by fatigue, and the fracture initiated at the bottom corner radius of the keyway. The keyway and splines had been overloaded beyond their yield strength, and significant yielding was observed in the spline gear teeth. A fracture ring of non-standard alloy steel exhibited a sharp corner radius, which was a significant stress raiser.

Several components were studied to determine their life span. These components include the spline shaft, the sealing bolt, and the graphite ring. Each of these components has its own set of design parameters. However, there are similarities in the distributions of these components. Wear and fatigue failure of spline couplings can be attributed to a combination of the three factors. A failure mode is often defined as a non-linear distribution of stresses and strains.

editor by czh 2023-02-15

in Kuala Lumpur Malaysia sales price shop near me near me shop factory supplier Europe Hot Selling Dq504 50HP 4X4 4WD China Mini Garden Farm Compact Tractor with Ce Certificate manufacturer best Cost Custom Cheap wholesaler

The large specific CNC products, these kinds of as Gradual-feeding wire-lower device, jig grinding machine and electric powered discharge machine, makes certain the leading high quality precision of mould processing, with the high effective and environmental defense acid rolling line getting the greatest uncooked substance converting equipment in the discipline in china The wildly use of computerized milling device, high-pace automatic feeding punch, large velocity computerized rolling and assembling machine guarantees the high quality and effectiveness of factors and chain making. Our company pays particular attention to customers’ needs, listening to the specific demands of each buyer and guaranteeing whole satisfaction. With comprehensive requirments, we can also develop your specific created solution. Europe very hot promoting DQ504 50HP 4×4 4 wheel drive EPTT Mini XiHu (West EPT) Dis.Hu (West EPT) Dis.den Farm compact tractor with CE certificate

Tractor Major Features and Rewards:

1.Geared up renowned brand name motor displaying EPTd potential, minimal gasoline consumption and high financial efficiency.

2. Streamlined appearance design and style, gorgeous and generous.

three.EPTT Case undertake meshed change and include the EPTT interlock system can make the operation a lot more effortlessly, dependable and less complicated.

four. EPTT motion clutch with disc EPT, execute steadily and simple to operate.

5. Completely EPT steering technique tremendously decreased EPTr’s work power.

6. Damp disc brake gadget, reliable brake efficiency.

seven. Separate EPT of EPT oil, trustworthy to operate.

eight. The lifter with power and position adjustment, with dependable carry.

9. Tractor PTO:

PTO in EPTT speed : 540/a thousand, 760/a thousand, 540/760r/min Optional, For higher doing work performance.

PTO shaft of six or eight spline Optional, adaptable for agricultural equipment of all in excess of the entire world.

ten. Full collection mild, ROPS,Sunshade/Canopy, Fan/Heater/Air-conditioned cabin are all offered, for more comfortable driving surroundings.

Tractor Primary specificaiton and EPTnical parameters:

| Tractor Product | DQ504 |

| Push kind | 4×4 |

| Engine | |

| Type of motor | XiHu (West EPT) Dis.nchai four-Cylinder EPTT motor |

| Capability of fuel tank(L) | 38L |

| Engine EPTT at rated pace | 36.8kw / 50HP |

| Rated velocity (r/min) | 2400 |

| EPTT | |

| EPTT | dry,twin-stage type |

| PTO velocity | 540/1000rpm or 540/760rpm |

| EPT change | 8F 4R/8F 8R/12F 12R (Optional) |

| EPT system | |

| EPT output valve | two-Way (optional) |

| Three point linkage | |

| Group of 3-level hyperlink | rear, classification II |

| EPT pressure (at position of 610mm)KN | 12 |

| EPTnical parameter | |

| Overall dimensions (L x W x H)mm | 3513x1750x2130 |

| Wheel base (mm) | 2040 |

| The smallest clearance (mm) | 325 |

| Entrance tire | eight.3-20 |

| Rear tire | twelve.4-28/fourteen.nine-24 (optional) |

| Optional Configurations | |

| ROPS,Cover(Sunshade),Cabin with Fan/Heater/Air-situation, 2-Team EPT output valve, Front ballast, Rear ballast,Air brake, 8F 8R/12F 12R Shuttle EPTshift,Paddy tire, fourteen.nine-24 huge rear tire, EPTg attract bar. | |

DQ504 50HP 4 wheel drive tractor detail demonstrating:

DQ504 50HP Four wheel drive tractor have A variety of Optional configurations for decide on:

Progress Manufacutring Line:

DQ504 50HP Four wheel drive Tractor EPTT and Shipping and delivery transporting:

EPT good quality Tractor have ISO,CE, PVOC COC, CO, and so forth certificates:

Best right after-sale provider for each Distributors and Private consumers:

Please speak to us if you have any need for our Product :

EPTT price tag will be quoted for you as quickly as EPT your Prerequisite !

in Erbil Iraq sales price shop near me near me shop factory supplier New Multifunctional Tractor Dq704A 70HP 4WD Agricultural Wheel Farm Tractor with Tz08d Front End Loader manufacturer best Cost Custom Cheap wholesaler

Our items are manufactured by present day computerized equipment and products. Thanks to our sincerity in supplying greatest service to our customers, comprehending of your demands and overriding feeling of duty toward filling buying needs, Our goods are utilized in numerous fields. EPTT multifunctional Tractor DQ704A 70HP Four wheel drive EPTT wheel Farm Tractor with TZ08D Front stop loaEPTT

Tractor Primary Functions and Rewards:

1.Equipped famous manufacturer motor exhibiting EPTd capability,lower gasoline intake,substantial economic performance.

2. Streamlined look layout, stunning and generous.

3.EPTT Scenario adopt meshed shift and include the EPTT interlock unit helps make the procedure a lot more smoothly,reliable and less complicated.

4. EPTT action clutch with disc EPT, complete steadily and easy to run.

five. Fully EPT steering system greatly decreased EPTr’s perform toughness.

6. Damp disc brake system, reliable brake overall performance.

7. Individual EPT of EPT oil, reputable to run.

8. The lifter with force and situation adjustment, with reliable elevate.

9. Tractor PTO:

PTO in EPTT speed : 540/760 or 1000 r/min Optional, For large functioning efficiency.

PTO shaft of 6 or 8 spline Optional, adaptable for agricultural tools of all over the globe.

10. Large Chassis and EPT-duty Rear axle for EPTTble EPT EPTT.

11. Full collection gentle, ROPS,Sunshade/Cover, Enthusiast/Heater/Air-conditioned cabin are all accessible, for a lot more comfortable driving environment.

Tractor Major specificaiton and EPTnical parameters:

| Product | DQ704A | |

| Drive sort | 4×4, 4 wheel EPT | |

| Engine | ||

| Brand name | EPTchai or YTO | |

| Kind of motor | 4 cylinder, in-line, h2o amazing, organic aspirate | |

| Model | YT4B4-22 | |

| Bore x stroke | 108 x 130mm | |

| Displacement | four.76L | |

| Ratio | 18:one | |

| Capability of gas tank(L) | 125L | |

| Engine EPTT at rated speed (kw) | 51.five | |

| Rated speed (r/min) | 2200 | |

| Gasoline tank ability (L) | 125 | |

| EPTT | ||

| EPTT | soaked,dual-phase sort | |

| EPT box | 8F 8R or 12F 12R shuttle EPTshift | |

| EPT box variety | Joggle include sort | |

| Differential | Shut type, four planetary EPTTl EPT | |

| Tyre | ||

| Front tire | 8.three-24 /9.5-20(optional) | |

| Rear tire | 11-32 /fourteen.9-28(optional) | |

| Operating device | ||

| A few point linkage | Rear, category II, force, place manage | |

| EPT output gadget | two-Group (optional) | |

| PTO sort | Semi-different, 6 spline, 540/760rpm | |

| EPTnical parameter | ||

| Steering | EPT steering | |

| Brake sort | Moist, disc type | |

| Total dimension (LxWxH) (mm) | 3593x1850x2568 | |

| Weight (kg) | 2550 | |

| Wheel foundation(mm) | 2040 | |

| Track foundation (mm) | Entrance wheel | 1250-1350 |

| Rear wheel | 1300-1500 | |

| The smallest clearance (mm) | 370 | |

| Entrance tire | 8.three-24 | |

| Rear tire | 11.-32 | |

| Optional Configuration | ||

| ROPS, Canopy(Sunshade), Front ballast, Rear ballast, Enthusiast cabin, Heater cabin, Air-conditioning cabin, 2-Team EPT output valve, Big R1 tire F9.5-20/R14.9-28, Paddy tires, Air brake, EPTg attract bar | ||

| Loading EPTtity/Container | one established/20ft container, 3 sets/40HQ | |

DQ704A 70HP 4wd Tractor details present :

TZ08D CE Acceptance Euro swift hitch variety Front finish loaEPTT:

TZ08D Tractor Front conclude loaEPTTMain Characteristics and Usage :

one.Utilized in Shoveling, stacking or quick-distance transportation of free substance, like mud, sand, stone or XiHu (West EPT) Dis.Hu (West EPT) Dis.bage.

two.Featured with compact structure, fleXiHu (West EPT) Dis.bility, practical procedure and rapid mounting and dismounting.

3.EPT EPTT is utilised,Showcased with compact composition, fleXiHu (West EPT) Dis.bility, handy procedure and swift mounting and dismounting.

It uses EPT oil commonly with tractor. The EPT aspects are stXiHu (West EPT) Dis.Hu (West EPT) Dis.rdized, hassle-free for operation and support.

four.Various operate gadgets are optional, this kind of as merged buckets(4 in one Bucket), grating include bucket, pallet handler, timber seize and bale fork, etc,

so as to attain diverse types of operate effectively.

TZ08D Front conclude loaEPTTSpecifications:

| Front Stop Loader Design | Device | TZ08D |

| Matching Tractor | hp | 55-seventy five |

| Rated EPT Ability | kg | 800 |

| Max.EPT peak@EPTTlement Pivot pin | mm | 3400 |

| Max. Dumping top | mm | 2480 |

| Overloading height | mm | 3220 |

| Dumping length | mm | 690 |

| Floor Clearance @Arm pivot pin | mm | 1630 |

| Digging depth | mm | a hundred and forty |

| Bucket width (stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd) | mm | 1600 |

| Bucket Capacity | m3 | .40 |

| Max Tip in Angle | degree deg | 54 |

| Dump Angle | diploma deg | fifty eight |

| Crowd angle @decreased lift arm | degree deg | 135 |

| Rated EPT Capability | kg | 800 |

Front finish loaEPTTdetails:

Advance Manufacutring Line:

Strictly Inspecting and Entire Tests for making certain substantial high quality item:

Customlized Tractor EPTT and Transporting support to fulfill diverse clients demand

Remember to Get in touch with us if you have any demand for our Merchandise

EPTT cost will be quoted for you as soon as EPT your Necessity !

in Riyadh Saudi Arabia sales price shop near me near me shop factory supplier Agricultural Tractor 100HP 4X4 Wheel Drive Diesel Farm Tractors manufacturer best Cost Custom Cheap wholesaler

Moreover, WE CAN Generate Customized VARIATORS, GEARED MOTORS, Electric MOTORS AND OTHER HYDRAULIC Goods In accordance TO CUSTOMERS’ DRAWINGS. There is a technical middle of province stage, EPG academician functioning station, experiment station for EPG put up physicians, and countrywide 863 plan set up in EPG team. With these platforms and sturdy technical capacity, the much more than 400 professionals have designed all variety of special large precise and higher energy merchandise, executed mold packages for key elements in the automobile and national market revitalizing plan, resulting a lot more than 5000 produced more than, between which 33 things are autonomous patent technology with four patent accepted . The item effectively displays environmental defense and power saving.

Features of EPTT1004 Tractor

(1) This sort of tractor is suitable for mechanized manufacturing of farming, EPTTful and productive.

(2) EPT procedure, great protection variables.

(3) Good quality and provider eEPTTly soon after-revenue provider

(four) F16 R8 EPTs shifts arranged with proper speed. Wide adaptability makes procedure in farm fields and transportation much more less complicated.

(five) Enlarged 150L double underslung oil tanks make certain the EPTT time procedure.

(6) With higher trustworthiness even though running in the paddy subject for a entrance transaxle, which is completely shut.

(7) Deluxe cab, easy operation.

(8) Can put in well-known domestic engines like EPT, YTO, EPTchai.

(nine) EPTT velocity PTO 540/1000rpm or 720/a thousand rpm you can choose, satisfying the matching with diverse farming implements.

(ten) Reinforced PTO shaft, hello-dependability.

(11)80A sequence of tractors ( tractors from 80hp to 100hp) depict the new technology of non-public sector producing in EPTT. A rugged EPTT constructed for professional dependability and stamina.

(12)The EPTTs are straightforward to function with operator ease and comfort and security presented the maximum precedence. The basic effortless to obtain EPT program supplies the ideal driving expertise for the operator. The EPTT has effortless EPTT steering and quite relaxed seating.

(13)The steel development bonnet and guards a created to very last and handle the knocks and bruises. Combine this with the trustworthy EPTT stroke large torque 4 cylinEPTTeasy start off diesel motor and you have a EPTT that is really a pleasure to operate with. Dual EPT pumps ensure you alwaEPTThave the EPT movement required for steering and EPTTed implements

EPTnical Information

| Design | EPTT1004 | TS1004 | ||||

| EPTT Specifications | Variety | 4×4 | 4×4 | |||

| All round dimensions L*W*H(mm) | 4481 times2042 times2829 | 4481 times2042 times2829 | ||||

| EPTTal fat(kg) | 4000 | 4000 | ||||

| Rated traction force(kn) | 36 | 36 | ||||

| Wheel base(mm) | 2385 | 2385 | ||||

| Front wheel tread(mm) | 1650~2015(Adjustable) | 1650 ~2015(Adjustable) | ||||

| Rear wheel tread(mm) | 1504~2074(Adjustable) | 1504~2074(Adjustable) | ||||

| Min. land clearance(mm) | 435 | 435 | ||||

| Min. high quality in use(kg) | 4600 | 4600 | ||||

| Entrance wheel tyre size | 12.four-28 | 12.four-28 | ||||

| Rear wheel tyre dimensions | sixteen.9-38 | sixteen.9-38 | ||||

| Min.turning radius(mm)(Unilateral Nonbraking/Unilateral Braking) | 4300/3650 | 4300/3650 | ||||

| Theoretical pace(km/h) | I | II | III | Reverse | ||

| EPT EPT | C | forty.7 | 33.five | forty.seven | 33.5 | |

| B | 24.4 | 20.2 | 24.four | twenty.2 | ||

| A | fifteen | twelve.five | 15 | twelve.five | ||

| Minimal EPT | C | nine.7 | eight | nine.7 | 8 | |

| B | 5.9 | 4.8 | 5.9 | four.8 | ||

| A | 3.6 | three | 3.six | three | ||

| Creeper | C | 2 | one.6 | 2 | one.six | |

| B | one.three | one.1 | one.three | 1.1 | ||

| A | .7 | .6 | .7 | .six | ||

| Engine | Design | TD226B-4T | ||||

| Type | VerticalWater-coolingFour-strokedirect EPT | |||||

| 12 hours EPTT(kw) | seventy three.5 | |||||

| Rated velocity(r/min) | 2400 | |||||

| Gas usage(g/kw.h) | lt=242 | |||||

| Max.torque(n.m) | gt=364 | |||||

| Velocity of Max.torque(r/min) | 1500-1700 | |||||

| Bore stroke(mm) | Phi105*one hundred twenty five | |||||

| EPTT intake(g/kw.h | lt=one.63 | |||||

| Starting method | Electrical start off | |||||

| Break System | Support brake | EPTEPTWetDisc | ||||

| Parking brake | EPT controlMultipleWetDisc | |||||

| EPTT | EPTT | DrySingle pieceIndependent operationEPTT performing | ||||

| EPT box | Blend fashion(three one)*3*two:18 EPTT EPT,six reverse EPTEquipted with creeper(3 one)*three*three:27 EPTT EPT,9 reverse EPTMain EPT box:EPTT engaged by indirect EPT | |||||

| Steering | EPT steering | |||||

| Steering type | Front wheel steering | |||||

| Primary EPT | Spiral EPTTl EPT | |||||

| Differential mechanism | Four world EPTTl EPTClosed | |||||

| Ultimate EPT | InternalPlanetary EPT | |||||

| Operating Method | Lifter tilling depth management | Draft ampposition adjustable | ||||

| Max.lifting capacity(kn) | gt=twenty five | |||||

| Suspension kind | PostpositionThree-pointII classification | |||||

| Pace of P.T.O.(r/min) | (540,a thousand) or (720,one thousand) or (540,720) | |||||

| Sort of P.T.O. | Impartial and synchronous P.T.O. | |||||

| Traction EPT | EPTg rod | |||||

| Optional Disposition | Front ballastRear ballastAir brakeNo cabin and no EPT outputLR6105T55 motor | |||||

We have possibility to participate in the EPTs, and appeals to a lot of international buyers. Our operate net has EPT all over the globe. Our merchandise have been exported to numerous other nations, this sort of as Romania, Russia, TEPTTd, Australia, and many others.

If you are fascinated in our tractors, pls come to feel free of charge to speak to us.

in Owerri Nigeria sales price shop near me near me shop factory supplier Safety Tractor Mounted Woodworking Machine, Hydraulic Bx62r Wood Crusher manufacturer best Cost Custom Cheap wholesaler

With EPG manufacturer registered in more than 70 nations like The usa , Europe , Japan and so on, it has companions among entire world top enterprises, such as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so forth. Our items are applied in a lot of fields. Owing to our sincerity in providing ideal service to our consumers, comprehension of your wants and overriding perception of obligation toward filling buying specifications,

Product Description:

The chipper has two EPT motors with a reverse function that pulls the branches, shrubs to the chopper rotor.

The chopper rotor has 4 knives, which are tightly attached to the rotor with screws.

The diameter of the chopper rotor is ~ 77 cm, the rotor weigEPTT is ~ 90 kg.

The size of the fridge loading hopper is ~ 63x63cm, the loading hole at the rotor is ~ 17x30cm.

The chopper chip blasting pipe heigEPTT is ~ 188cm, the blower tube is 360 degree.

The chopper is equipped to the tractor with a 3-position hitch, the rotor is EPTn from the tractor’s PTO (540-a thousand rpm), hydro motors are EPTn from the tractor’s EPT system. The chipper feed rolls have a reverse perform.

The required tractor has a capacity from 40 hp to a hundred hp, but the optimum EPTT and gasoline intake ratio for chipper for the maXiHu (West EPT) Dis.mum measurement (diameter 15cm) for logging calls for a tractor with a capability of 60-70 hp.

Package:

EPTnical Technical specs:

FAQ:

in Kazan Russian Federation sales price shop near me near me shop factory supplier Tractor Portable Spring Cultivator Mini Pto Shaft Rotary Tiller manufacturer best Cost Custom Cheap wholesaler

Thanks to our broad item variety and rich encounters in this market, The team has taken component in the making and revising of ISO/TC100 international chain regular a number of years in achievement and hosted the sixteenth ISO/TC100 Intercontinental once-a-year meeting in 2004. The team is focused on producing all assortment of normal roller chains and sprockets, gears & gearboxes, this sort of as conveyor chain & sprockets , stainless metal chain, agricultural chain and has not just marketed its products all more than china, but also marketed far more than sixty five% merchandise to oversees, including Europe, The united states, South-east Asia, and it also has set up storage logistics in areas like Europe.

Specification:

| Mode | RT-eighty five | RT-ninety five | RT-105 | RT-115 | RT-125 | RT-135 |

| Dimension(mm) | 950*550*560 | 1050*550*560 | 1150*550*560 | 1250*550*560 | 1350*550*560 | 1450*550*560 |

| Doing work width(cm) | 85 | 95 | a hundred and five | 115 | a hundred twenty five | one hundred thirty five |

| PTO Enter velocity(rpm) | 540r/min | 540r/min | 540r/min | 540r/min | 540r/min | 540r/min |

| Bodyweight(Kg) | 110kg | 115kg | 125kg | 135kg | 145kg | 155kg |

| Quantity of blades | sixteen | 16 | 20 | 24 | 28 | 32 |

| Tilling depth(cm) | eight-twelve | eight-twelve | 8-12 | eight-twelve | eight-12 | 8-twelve |

| EPTT dimensions(mm) | 1060*650*660 | 1160*650*660 | 1260*650*660 | 1360*650*660 | 1460*650*660 | 1560*650*660 |

| EPTT necessary | 15-25HP | 15-25HP | 15-25HP | 20-30HP | twenty-30HP | twenty-30HP |

————————— Solution ATTRIBUTE ————————-

1. EPTT: EPTT EPTn.

2. Gravity EPTT is created of casting iron. EPT overall performance is EPT. Not simple damaged.

three. The suspension plate shape is not easy to deform.

four. EPTT system hand adjustable. More effortless and reliable.

five. Facet defense plates are additional on to the rear deflection. This system prevents the soil traveling out.

six. The tilling heigEPTT can be adjustable.

seven. The framework is company and stable.

———————-

EPTT Profile

HangEPT EPT Industry amp EPT EPTT, Ltd., is a specialist maker and exporter of EPTT set of EPT EPTTs and XiHu (West EPT) Dis.Hu (West EPT) Dis.den tools. Our company was estabEPTTd because 2003 with Hanma Business EPTT.

Our main merchandise incEPTT rotovator, flail mower, finishing mower, topper mower, wood chipper, plow, cultivator, potato harvester/ EPTTer and Japanese tractor components, and many others. Because of to our tremendous Worldwide high quality stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd and fast amp exceptional soon after-revenue provider, EPT EPTTs are drastically well-liked in numerous marketplaces around the planet, and presently arrived at to Europe, North America, South The usa, Australia, practically addresses 80 countries in EPT.

EPT alwaEPTTbelieve that we will just take EPT farming existence to you by prime-good quality laser chopping EPTT amp CNC bending EPTT amp expert paint-spraying amp sturdy welding.

Skilled Manufacturing:

1.Professional crew with prosperous experience

two.EPTTful manufacturing unit energy with EPTT

3.EPTT soon after-product sales support

EPTT amp EPT

EPTT Element: Iron pallet or picket cases

Shipping Depth: By sea or By air

1. Waterproof EPTT with the international export stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd by 20ft, 40ftcontainer.

EPTen Circumstance or Iron Pallet.

two. The EPTT established of EPTTs dimensions are massive as typical, so we will use Water-resistant materials to pack

all of them. The motor, EPT box or other very easily damaged areas, we will put them into box.

We have a professional transport division, they will try their very best to preserve your container amount.

EPTT movies in YOUTOBE

https://youtu.be/UCDWDR3Pjrg EPT organization online video

https://youtu.be/Bc8UzmpHiyU EFD flail mower

https:///look at?v=Bh73zRIYBpc EFDL Facet MOWERS

https:///observe?v=ZuWSCmiPows EFGL Side MOWERS

https:///view?v=iH6uEPTTqEyuQ FM FEPTSHING MOWERS

https:///view?v=VLUEyam_5DY TM TOPPER MOWERS

https:///view?v=jphaylxaKUg RT ROTARY TILLERS

https://youtu.be/d3H1-yXUImc AP-90 POTATO EPTRVESTER

https://youtu.be/AAkgnV_bY80 EPTT-PT32 POTATO PLANTER

https://youtu.be/66geQQOUTLY wood chipper BX-forty two

https://youtu.be/iIVOwCTCl_c EPTY BALER

FAQ:

Q1. How to acquire 3 stage rotary tiller?

Inquiry ——— gt Quotation ——– gtPrice sensible ——- gtCheck with specification —– gtProforma Bill sent ———— gtPayment produced ——- gt Making the items ——- gtProduct shipment ———– gt Customer validate

Q2.How EPTT is the shipping and delivery date for EPT EPTTry cultivator?

A:In EPTT, we can ship the merchandise in thirty-45 daEPTTafter receiving your payment. Of course, it also relies upon on your quantity.

Q3. How can I get to your manufacturing unit to buy tractor cultivator?

A:We are located in HangEPT, only a single hour’s length to ZheJiang or NanEPTTg. You can fly to ZheJiang /NanEPTTg/HangEPT Airport , the transportation is really handy

Q4.Do you have inventory for rotary tiller?

A:In EPTT, we have some inventory, although if you need to have a bulk purchase, we still need to have time to create it. Of training course, we will inform all details you ahead of your payment.

Q5: What is actually your principal goods?

A: Our goods are coated practically all farm EPTTs and Japanese tractors elements, we can satisfy your any calls for.

Q6. What is your phrases of payment?

A: T/T, L/C, Paypal, Western EPT