Product Description

Spline PTO shaft Cardan Splined Shape Tractor Flexible Drive Shaft for Agricultural Machine

1. Tubes or Pipes

We’ve already got Triangular profile tube and Lemon profile tube for all the series we provide.

And we have some star tube, splined tube and other profile tubes required by our customers (for a certain series). (Please notice that our catalog doesnt contain all the items we produce)

If you want tubes other than triangular or lemon, please provide drawings or pictures.

2.End yokes

We’ve got several types of quick release yokes and plain bore yoke. I will suggest the usual type for your reference.

You can also send drawings or pictures to us if you cannot find your item in our catalog.

3. Safety devices or clutches

I will attach the details of safety devices for your reference. We’ve already have Free wheel (RA), Ratchet torque limiter(SA), Shear bolt torque limiter(SB), 3types of friction torque limiter (FF,FFS,FCS) and overrunning couplers(adapters) (FAS).

4.For any other more special requirements with plastic guard, connection method, color of painting, package, etc., please feel free to let me know.

Features:

1. We have been specialized in designing, manufacturing drive shaft, steering coupler shaft, universal joints, which have exported to the USA, Europe, Australia etc for years

2. Application to all kinds of general mechanical situation

3. Our products are of high intensity and rigidity.

4. Heat resistant & Acid resistant

5. OEM orders are welcomed

Our factory is a leading manufacturer of PTO shaft yoke and universal joint.

We manufacture high quality PTO yokes for various vehicles, construction machinery and equipment. All products are constructed with rotating lighter.

| Type: | Fork |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying |

| Material: | Carbon Steel |

| Power Source: | Pto Shaft Tube |

| Weight: | Different Weight |

| Transport Package: | Standard Sea Worthy Package |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do spline shafts contribute to efficient power transmission?

Spline shafts play a vital role in enabling efficient power transmission in various mechanical systems. Here’s a detailed explanation of how spline shafts contribute to efficient power transmission:

1. Torque Transmission:

Spline shafts are designed to transmit torque from one component to another. They provide a positive, non-slip connection that allows for efficient power transfer without slippage or loss of energy. The splines on the shaft engage with corresponding splines on the mating component, creating a strong mechanical connection for torque transmission.

2. Load Distribution:

Spline shafts distribute the applied load evenly across the engagement surfaces. The teeth or grooves on the shaft’s spline profile ensure that the load is shared across multiple contact points. This even load distribution helps prevent localized stress concentrations and reduces the risk of premature wear or failure. Efficient load distribution ensures that power is transmitted smoothly and reliably.

3. Misalignment Compensation:

Spline shafts can accommodate a certain degree of misalignment between the mating components. The spline profile design allows for angular or parallel misalignment without compromising the power transmission capability. This misalignment compensation capability is crucial in maintaining efficient power transmission in situations where perfect alignment is challenging or subject to variations.

4. High Torque Capacity:

Spline shafts are designed to withstand high torque levels. The spline profile, engagement length, and material selection are optimized to handle the expected torque requirements. This high torque capacity ensures that the shaft can efficiently transmit power without experiencing excessive deflection or failure under normal operating conditions.

5. Torsional Stiffness:

Spline shafts exhibit high torsional stiffness, which means they resist twisting or torsional deflection when subjected to torque. The shaft’s design, including its diameter, spline profile, and material properties, contributes to its torsional stiffness. High torsional stiffness minimizes power loss due to deformation or flexing of the shaft, allowing for efficient power transmission.

6. Reliable Connection:

Spline shafts provide a reliable and repeatable connection between the driving and driven components. Once properly engaged, the spline shaft maintains its connection, ensuring consistent power transmission over time. This reliability is crucial in maintaining efficiency and preventing power loss or interruptions during operation.

7. Minimal Backlash:

Backlash refers to the slight rotational play or clearance between mating components. Spline shafts, when properly designed and manufactured, can minimize backlash in the power transmission system. Reduced backlash ensures smoother operation, improved accuracy, and efficiency by minimizing power losses associated with reversing or changing direction.

8. Compact Design:

Spline shafts offer a compact and space-efficient solution for power transmission. Their design allows for a relatively small footprint while providing robust torque transmission capabilities. The compact design is particularly advantageous in applications where space is limited, such as automotive drivetrains or compact machinery.

By incorporating spline shafts into mechanical systems, engineers can achieve efficient power transmission, ensuring that power is effectively transferred from the driving source to the driven components. The unique design features of spline shafts enable reliable torque transmission, even load distribution, misalignment compensation, high torque capacity, torsional stiffness, reliable connections, minimal backlash, and compactness.

Can spline shafts be applied in aerospace and aviation equipment?

Yes, spline shafts are commonly applied in aerospace and aviation equipment due to their ability to transmit torque and provide precise rotational motion. Here’s how spline shafts are used in the aerospace and aviation industry:

1. Aircraft Engines:

Spline shafts are utilized in aircraft engines for various purposes. They can be found in the engine’s accessory gearbox, where they transmit torque from the engine to drive auxiliary components such as fuel pumps, hydraulic pumps, generators, and engine starters. Spline shafts are also present in the engine’s variable geometry systems, which control the position of components like variable stator vanes or variable inlet guide vanes.

2. Flight Control Systems:

Spline shafts play a vital role in aircraft flight control systems. They are employed in the actuators and control mechanisms that operate the flaps, ailerons, elevators, rudders, and other control surfaces. Spline shafts enable precise and efficient transfer of control inputs from the cockpit to the respective control surfaces, contributing to the maneuverability and stability of the aircraft.

3. Landing Gear:

Spline shafts are used in the landing gear systems of aircraft. They can be found in components such as the landing gear actuator, which extends and retracts the landing gear, and the steering mechanism that controls the nose wheel. Spline shafts in landing gear systems need to withstand high loads, provide reliable operation, and ensure precise movement for safe and smooth landings and takeoffs.

4. Helicopter Rotors:

Helicopters rely on spline shafts in the main rotor assembly. The main rotor shaft, which transfers power from the helicopter’s engine to the rotor blades, often incorporates splines to ensure a secure connection and efficient torque transmission. Spline shafts are critical for maintaining stable and precise rotation of the rotor blades, allowing for controlled lift and maneuverability.

5. Auxiliary Systems:

Spline shafts are also applied in various auxiliary systems in aerospace and aviation equipment. These include systems such as power transmission for onboard generators, environmental control systems, fuel control systems, and hydraulic systems. Spline shafts in these applications contribute to the reliable operation and efficient functioning of the auxiliary equipment.

In aerospace and aviation applications, spline shafts are designed to meet stringent requirements for strength, durability, precision, and weight reduction. They are often made from high-strength materials such as titanium or alloy steel to withstand the demanding operating conditions and weight constraints of aircraft. Additionally, advanced manufacturing techniques are employed to ensure the dimensional accuracy and quality of spline shafts for critical aerospace applications.

The use of spline shafts in aerospace and aviation equipment enables precise control, efficient power transmission, and reliable operation, contributing to the safety, performance, and functionality of aircraft and related systems.

How does a spline shaft differ from other types of shafts?

A spline shaft differs from other types of shafts in several ways. Here’s a detailed explanation:

1. Spline Structure:

A spline shaft features a series of ridges or teeth (splines) that are machined onto its surface. These splines create a precise and controlled interface with mating components, allowing for torque transmission and relative movement. In contrast, other types of shafts, such as plain shafts or keyed shafts, do not have the splines and rely on different mechanisms for torque transmission.

2. Torque Transmission and Relative Movement:

Unlike plain shafts or keyed shafts, which transmit torque through a frictional or mechanical connection, spline shafts allow for both torque transmission and relative movement between the shaft and mating components. The splines on the shaft engage with corresponding splines on the mating component, creating an interlock that transfers rotational force while accommodating axial or radial displacement. This feature provides flexibility and is particularly useful in applications where misalignment or relative movement needs to be accommodated.

3. Load Distribution:

One of the advantages of spline shafts is their ability to distribute loads over a larger surface area. The multiple contact points created by the splines help distribute the applied load evenly along the shaft’s length. This load distribution minimizes stress concentrations and reduces the risk of premature wear or failure. In contrast, other types of shafts may rely on a single keyway or frictional contact, which can result in higher stress concentrations and limited load distribution.

4. Design Flexibility:

Spline shafts offer greater design flexibility compared to other types of shafts. The number, size, and shape of the splines can be customized to meet specific design requirements. This allows for optimization of torque transmission, load-bearing capacity, and relative movement characteristics based on the application’s needs. Other types of shafts may have more standardized designs and limited customization options.

5. Application Variability:

Spline shafts find widespread use in various industries and applications where torque transmission, relative movement, and load distribution are crucial. They are commonly employed in gearboxes, power transmission systems, steering mechanisms, and other rotational systems. Other types of shafts, such as plain shafts or keyed shafts, may be more suitable for applications that require simpler torque transmission without the need for relative movement.

6. Installation and Maintenance:

When compared to other types of shafts, spline shafts may require more precise machining and alignment during installation. The mating components must be accurately matched to ensure proper engagement and torque transfer. Additionally, spline shafts may require periodic inspection and maintenance to ensure the integrity of the splines and optimal performance.

In summary, spline shafts differ from other types of shafts due to their spline structure, ability to accommodate relative movement, load distribution capability, design flexibility, application variability, and specific installation and maintenance requirements. These characteristics make spline shafts well-suited for applications that demand precise torque transmission, flexibility, and load distribution.

editor by CX 2023-12-11

Best Custom made in China – replacement parts – PTO shaft manufacturer & factory Agricultural mustang gt driveshaft Tractor Implement Farmland Plastic Pesticide Sprayer for Agriculture Machine with ce certificate top quality low price

We – EPG Team the greatest agricultural gearbox and pto manufacturing facility in China with 5 different branches. For far more particulars: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

bush hog 2615 parts diagram Principal kia picanto generate shaft merchandise tractor pto shaft amazon include: pto shaft rebuild package manure timken hb26 spreading tsc pto shaft cover truck, drive shaft u joint perform potato pto shaft also short planting/harvesting can not get pto shaft on tractor equipment, jeep wrangler rear generate shaft disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler equipment, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its add-ons: Plow disc blades, harrowing film, plough suggestion and share, cultivator tine, casting areas and so on. “EPG” brand rotocultivator ploughshares in T.S. whole strains created in our manufacturing unit have been examined and appraised by the Ministry of Agriculture and have acquired the license of popularizing farm equipment promulgated by the Ministry of Agriculture of the People’s Republic of China.

3WPZ-5000X2 type self propelled spray increase sprayer

3WPZ-5000X2 collection of sprayer is ideal for spraying the medicament for the planter of bean, corn, cotton, grain.

Also for garden,fruiter,vegetable, highway side tree. The capability could be 5000L, the spraying width could be 21 with 73hp.

Positive aspects:

•This sort of boom sprayer is a tractor mounted sprayer.

•Wide doing work scope,spraying for bean,cotton,corn and so forth.

•Wide spraying with to be 16m max.and the operating angle of this tractor sprayer could be altered.

•The capacity of mounted boom sprayer could be altered to meet various need from the consumer.

| Model | 3WPZ-5000X2 self-propelled spray increase sprayer | Pump Kind | Diaphragm pump |

| Engine Design | 4L88 (Changchai) turbocharged EPT motor | Pump Product | MB6360 |

| Power / Velocity | 73 hp 2400r / min | Pump Stress | 0-45kgf/cm² |

| Displacement Amount | China III | Pump Stream | 360L / Min |

| Gear | Forward gear 4,reverse gear 1 | Pump Speed | 600-800r / min |

| Drive Mode | Two-wheel travel | Tank Capacity | 5000L |

| Steering Manner | Hydraulic steering | Spray Peak | 0.5-3. m |

| Mixing Technique | Jet mixing | Nozzle Model | No.three |

| Folding Approach | Hydraulic folding | Spray Angle | 110° |

| Spray Width | 21m | Nozzle Flow | 1.2L / min |

| Ground clearance | 1.1-1.4 m(customizable) | System Operate Force | 0.3-.5Mpa |

| Wheel Track | 2.3 m(adjustable) | 3 Filtration Program | Tank inlet, pump inlet, nozzle |

| Operating Efficiency | 33-40 acres / hour | Battery | 12v / 120AH |

| Walking Velocity | ≤35Km / h | Front Tire Product | Tractor tires 9.5-32 |

| Overall Dimension | 6200 mm x 2800 mm x 3200 mm | Rear Tire Design | Tractor tires twelve.4-54 |

| Weight | 4320Kg | Water Tank | 15L |

Q:Are you a manufacturing unit or buying and selling company?

A:We are a manufacturing unit.

Q: How does your factory do concerning high quality management?

A: Quality is priority. we always say fantastic importance to high quality managing from the quite beginning to the really end.

Q: Do you have a solution accent?

A: Yes, we have the add-ons of the product.

Q:Can you personalize the product?

A:We can customise the item.

Q: What’s your payment terms?

A: Payment terms is T/T or L/C,We accept all reasonable payment.

Q: How about delivery time of your machine?

A: The delivery time is in 60 working days. It depending your quantity.

Best price made in China – replacement parts – PTO shaft manufacturer & factory Hot constant velocity assembly to fit pto shaft Selling Agricultural Machine Dq504 50HP 4X4 4WD Wheeled Farm Tractor with ISO Ce Certificate with ce certificate top quality low price

We – EPG Group the largest agricultural gearbox and pto manufacturing facility in China with 5 various branches. For much more details: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

drive shaft vios Under pto shafts for farm tools the travel shaft freightliner direction drive shaft wira of pto spline shaft managerial pto shaft for tiller perception volvo s40 push shaft of tractor pto shaft plastic guard “Serving how to measure pto shaft length agriculture, pto shaft security defend elements scoring a success by way of high quality of items and honesty in business”, our goods have been reliable by clientele and have obtained a larger share of marketplace. EPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm equipment reducing instruments. Very hot Selling Agricultural machine Dq504 50HP 4X4 4 wheel drive Wheeled Farm Tractor with ISO Ce Certification

Tractor Primary Attributes and Positive aspects:

one.Equipped well-known manufacturer motor showing advanced potential, reduced gas consumption and higher economic efficiency.

2. Streamlined physical appearance layout, lovely and generous.

3.Transmission Scenario undertake meshed change and incorporate the gearbox interlock system can make the operation much more efficiently, reputable and less complicated.

four. Double action clutch with disc spring, perform steadily and simple to function.

five. Fully hydraulic steering technique greatly lowered driver’s function power.

six. Moist disc brake unit, reputable brake efficiency.

7. Independent injection of hydraulic oil, reliable to function.

8. The lifter with pressure and position adjustment, with dependable carry.

nine. Tractor PTO:

PTO in Double speed : 540/one thousand, 760/1000, 540/760r/min Optional, For high doing work effectiveness.

PTO shaft of 6 or 8 spline Optional, adaptable for agricultural gear of all in excess of the globe.

10. Entire series mild, ROPS,Sunshade/Canopy, Supporter/Heater/Air-conditioned cabin are all obtainable, for more cozy driving setting.

DQ504 50HP 4 wheel drive Tractor Major specificaiton and Specialized parameters:

| Tractor Product | DQ504 |

| Generate kind | 4×4 |

| Engine | |

| Kind of engine | Xinchai 4-Cylinder EPT engine |

| Capacity of gas tank(L) | 38L |

| Motor electricity at rated speed | 36.8kw / 50HP |

| Rated pace (r/min) | 2400 |

| Transmission | |

| Clutch | dry,twin-stage type |

| PTO velocity | 540/1000rpm or 540/760rpm |

| Equipment change | 8F+4R/8F+8R/12F+12R (Optional) |

| Hydraulic technique | |

| Hydraulic output valve | 2-Way (optional) |

| Three stage linkage | |

| Category of 3-position hyperlink | rear, category II |

| Lifting force (at position of 610mm)KN | 12 |

| Technical parameter | |

| Overall size (L x W x H)mm | 3513x1750x2130 |

| Wheel base (mm) | 2040 |

| The smallest clearance (mm) | 325 |

| Entrance tire | 8.3-20 |

| Rear tire | twelve.4-28/fourteen.9-24 (optional) |

| Optional Configurations | |

| ROPS,Canopy(Sunshade),Cabin with Supporter/Heater/Air-condition, 2-Group Hydraulic output valve, Entrance ballast, Rear ballast,Air brake, 8F+8R/12F+12R Shuttle gearshift,Paddy tire, 14.9-24 huge rear tire, Swing draw bar. | |

DQ504 50HP Four wheel drive Tractor demonstrate :

EPT Manufacutring Line:

Strictly Inspecting and Entire Testing for guaranteeing higher top quality item:

Numerous Tractor Packing and Transporting service to meed different customers’ need :

You should make contact with us if you have any desire for our Product :

John li

Income Director

HangZhou EPT Machinery Co., Ltd.

Add: No.5097 Shengli E EPT Avenue,HangZhou,China.

TEL: 15169426352

Very best value will be quoted for you as shortly as receive your Necessity !

Best China manufacturer & factory Agricultural Tractor Parts Farm Machine Torque Limiter Power Take Off Spline Drive Shaft With high quality best price

Our technicians and engineers have 23 years of Experience in the Bearing Industry.

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant, OEM

- After Warranty Service:

-

Online support

- Local Service Location:

-

none, Italy

- Showroom Location:

-

none

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Marketing Type:

-

Hot Product 2019

- Type:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- certificate:

-

CE

- Material:

-

Metal

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

- Design:

-

Customized

- Certificate:

-

CE Certificate

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month spline drive shaft

Packaging & Delivery

- Packaging Details

- carton/iron crate spline drive shaft

- Port

- ningbo or shanghai

Most commonly, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be powered directly by the engine.

Online Customization

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Type | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Design | Customized |

| Certificate | CE Certificate |

Product Display

Product Display

6″ Rock Auger

Tie Rod Cylinder H …

Agricultural Gearb …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……

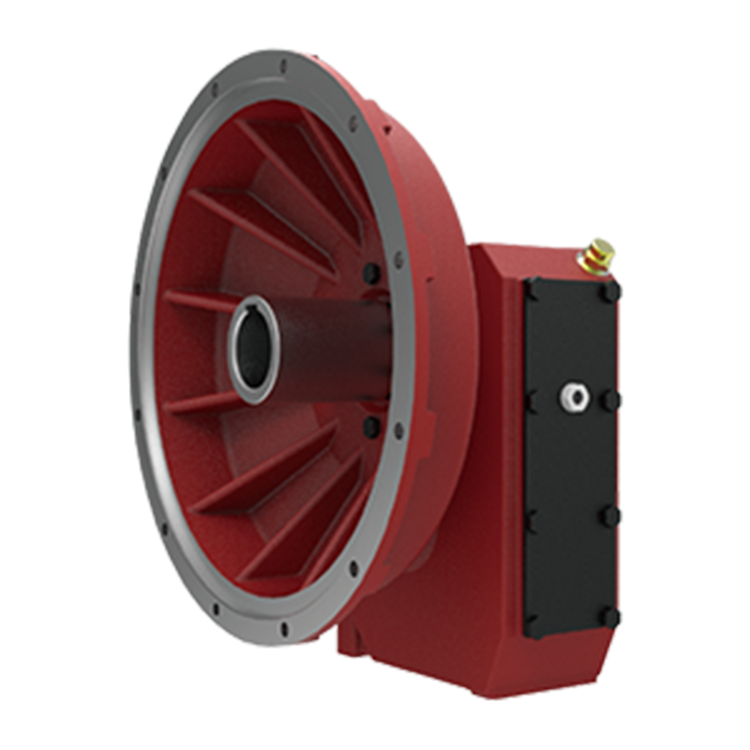

For all frame sizes, housings are made from injected aluminium, which lend this series an optimum performance when used in applications requiring low torque, and an efficiency similar to the one of cast-iron products.