Product Description

Product description

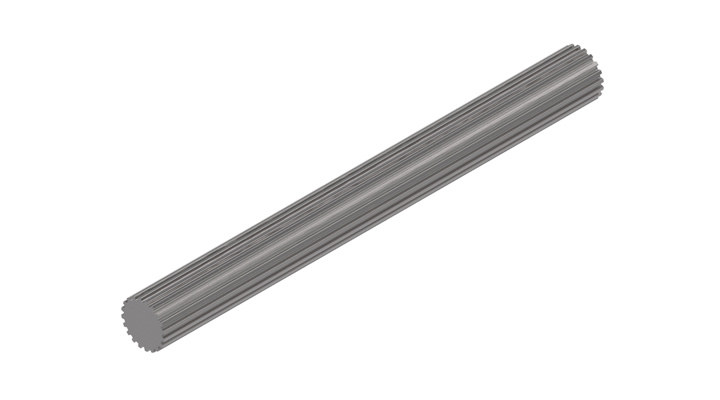

The spline is a kind of linear motion system. When spline motions along the precision ground Shaft by balls, the torque is transferred. The spline has compact structure. It can transfer the Over load and motive power. It has longer lifetime. At present the factory manufacture 2 kinds of spline, namely convex spline and concave spline. Usually the convex spline can take bigger radial load and torque than concave spline.

| Product name | Ball spline |

| Model | GJZ,GJZA,GJF,GJH,GJZG,GJFG, |

| Dia | 15mm-150mm |

| Material | Bearing Steel |

| Precision Class | Normal/ High/ Precise |

| Package | Plastic bag, box, carton |

| MOQ | 1pc |

Specifications

Ball type:φ16-φ250

High speed , high accuracy

Heavy load , long life

Flexible movement,low energy consumption

High movement speed

Heavy load and long service life

Applicationgs:semiconductor equipment,tire machinery,monocrystalline silicon furnace,medical rehabilitation equipment

Company profile

HangZhou CHINAMFG has a full performance laboratory of rolling functional components, high-speed ball screw pair 60m/min running noise 70dB, high-speed rolling linear guide pair 60m/min running noise 68dB, for precision horizontal machining center batch matching ball screw pair, rolling guide pair, to achieve each axis fast moving speed 40m/min, positioning accuracy 0.002mm, repeated positioning accuracy 0.001mm. Our equipments import from Japan and Germany and so on.

FAQ

Why choose AZI China?

With more than 60 years of production experience, quality assurance,factory directly price.

How can I get a sample to check the quality?

We quote according to your drawing, the price is suitable, CHINAMFG the sample list.

What is your main products ?

Our Main products are consist of ball screw,linear guide,arc linear guide,ball spline and ball screw linear guide rail module.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Gcr15 |

|---|---|

| Load: | Customized |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | Customized |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Samples: |

US$ 10/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can spline shafts be customized for specific machinery and equipment?

Yes, spline shafts can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation:

1. Size and Length:

Spline shafts can be customized in terms of size and length to fit the dimensions of the machinery or equipment. Manufacturers can design spline shafts with the appropriate diameter, overall length, and spline length to ensure a proper fit within the system.

2. Spline Profile:

The spline profile can be customized based on the specific application. Different spline profiles, such as involute, serrated, or helical, can be used to optimize torque transmission, load distribution, and engagement characteristics based on the requirements of the machinery or equipment.

3. Number of Splines:

The number of splines on the shaft can be customized to match the mating component. The number of splines determines the engagement area and affects the torque-carrying capacity of the spline shaft. By adjusting the number of splines, manufacturers can tailor the spline shaft to the specific torque and load requirements of the machinery or equipment.

4. Material Selection:

The choice of material for spline shafts can be customized based on the operating conditions and environmental factors of the machinery or equipment. Different materials, such as alloy steels or stainless steels, can be selected to provide the necessary strength, durability, corrosion resistance, or other specific properties required for the application.

5. Surface Treatment:

The surface of spline shafts can be customized with various treatments to enhance their performance. Surface treatments like heat treatment, coating, or plating can be applied to improve hardness, wear resistance, or corrosion resistance based on the specific requirements of the machinery or equipment.

6. Tolerances and Fit:

Tolerances and fit between the spline shaft and mating components can be customized to achieve the desired clearance or interference fit. This ensures proper engagement, smooth operation, and optimal performance of the machinery or equipment.

7. Special Features:

In certain cases, spline shafts can be customized with additional features to meet specific needs. This may include the incorporation of keyways, threads, or other specialized features required for the machinery or equipment.

Manufacturers and engineers work closely with the machinery or equipment designers to understand the specific requirements and tailor the spline shafts accordingly. By considering factors such as size, spline profile, number of splines, material selection, surface treatment, tolerances, fit, and any special features, customized spline shafts can be developed to ensure optimal performance and compatibility with the machinery or equipment.

It is important to consult with experienced spline shaft manufacturers or engineering professionals to determine the most suitable customization options for a particular machinery or equipment application.

Can spline shafts be repaired or maintained when necessary?

Yes, spline shafts can be repaired and maintained when necessary to ensure their continued functionality and performance. Here are some ways spline shafts can be repaired and maintained:

1. Inspection and Assessment:

When an issue is suspected with a spline shaft, the first step is to conduct a thorough inspection. This involves examining the shaft for any signs of wear, damage, or misalignment. Special attention is given to the spline teeth, which may show signs of wear or deformation. Through inspection and assessment, the extent of the repair or maintenance required can be determined.

2. Spline Tooth Repair:

If the spline teeth are damaged or worn, they can be repaired or replaced. Repair methods may include re-machining the teeth to restore their original profile, filling and reshaping the worn areas using specialized welding techniques, or replacing the damaged section of the spline shaft. The specific repair method depends on the severity of the damage and the material of the spline shaft.

3. Lubrication and Cleaning:

Regular lubrication and cleaning are essential for maintaining spline shafts. Lubricants help reduce friction and wear between the mating surfaces, while cleaning removes contaminants that can affect the spline’s engagement. During maintenance, old lubricants are removed, and fresh lubricants are applied to ensure smooth operation and prevent premature failure.

4. Surface Treatment:

If the spline shaft undergoes wear or corrosion, surface treatment can be applied to restore its condition. This may involve applying coatings or treatments to enhance the hardness, wear resistance, or corrosion resistance of the spline shaft. Surface treatments can improve the longevity and performance of the spline shaft, reducing the need for frequent repairs.

5. Balancing and Alignment:

If a spline shaft is experiencing vibration or misalignment issues, it may require balancing or realignment. Balancing involves redistributing mass along the shaft to minimize vibrations, while alignment ensures proper mating and engagement with other components. Balancing and alignment procedures help optimize the performance and longevity of the spline shaft.

6. Replacement:

In cases where the spline shaft is severely damaged or worn beyond repair, replacement may be necessary. Replacement spline shafts can be sourced from manufacturers or specialized suppliers who can provide shafts that meet the required specifications and tolerances.

It’s important to note that the repair and maintenance of spline shafts should be carried out by qualified professionals with expertise in precision machining and mechanical systems. They have the knowledge and tools to properly assess, repair, or replace spline shafts, ensuring the integrity and functionality of the system in which they are used.

By implementing regular maintenance and timely repairs, spline shafts can be kept in optimal condition, extending their lifespan and maintaining their performance in various mechanical applications.

What is a spline shaft and what is its primary function?

A spline shaft is a mechanical component that consists of a series of ridges or teeth (called splines) that are machined onto the surface of the shaft. Its primary function is to transmit torque while allowing for the relative movement or sliding of mating components. Here’s a detailed explanation:

1. Structure and Design:

A spline shaft typically has a cylindrical shape with external or internal splines. The external spline shaft has splines on the outer surface, while the internal spline shaft has splines on the inner bore. The number, size, and shape of the splines can vary depending on the specific application and design requirements.

2. Torque Transmission:

The main function of a spline shaft is to transmit torque between two mating components, such as gears, couplings, or other rotational elements. The splines on the shaft engage with corresponding splines on the mating component, creating a mechanical interlock. When torque is applied to the spline shaft, the engagement between the splines ensures that the rotational force is transferred from the shaft to the mating component, allowing the system to transmit power.

3. Relative Movement:

Unlike other types of shafts, a spline shaft allows for relative movement or sliding between the shaft and the mating component. This sliding motion can be axial (along the shaft’s axis) or radial (perpendicular to the shaft’s axis). The splines provide a precise and controlled interface that allows for this movement while maintaining torque transmission. This feature is particularly useful in applications where axial or radial displacement or misalignment needs to be accommodated.

4. Load Distribution:

Another important function of a spline shaft is to distribute the applied load evenly along its length. The splines create multiple contact points between the shaft and the mating component, which helps to distribute the torque and axial or radial forces over a larger surface area. This load distribution minimizes stress concentrations and reduces the risk of premature wear or failure.

5. Versatility and Applications:

Spline shafts find applications in various industries and systems, including automotive, aerospace, machinery, and power transmission. They are commonly used in gearboxes, drive systems, power take-off units, steering systems, and many other rotational mechanisms where torque transmission, relative movement, and load distribution are essential.

6. Design Considerations:

When designing a spline shaft, factors such as the torque requirements, speed, applied loads, and environmental conditions need to be considered. The spline geometry, material selection, and surface finish are critical for ensuring proper engagement, load-bearing capacity, and durability of the spline shaft.

In summary, a spline shaft is a mechanical component with splines that allows for torque transmission while accommodating relative movement or sliding between mating components. Its primary function is to transmit rotational force, distribute loads, and enable axial or radial displacement in various applications requiring precise torque transfer and flexibility.

editor by CX 2024-02-28

China High Bearing Capacity Spline Ball Shaft for Ball Screw Spline High Rigidity Ball Spline manufacturer

Solution Description

Solution description

The spline is a type of linear motion program. When spline motions alongside the precision floor Shaft by balls, the torque is transferred. The spline has compact construction. It can transfer the More than load and motive power. It has for a longer time life span. At present the manufacturing unit manufacture 2 kinds of spline, specifically convex spline and concave spline. Typically the convex spline can get greater radial load and torque than concave spline.

| Product name | Ball spline |

| Design | GJZ,GJZA,GJF,GJH,GJZG,GJFG, |

| Dia | 15mm-150mm |

| Content | Bearing Steel |

| Precision Course | Standard/ Large/ Specific |

| Package deal | Plastic bag, box, carton |

| MOQ | 1pc |

Specifications

Ball variety:φ16-φ250

High speed , large precision

Hefty load , long lifestyle

Flexible movement,reduced power consumption

Substantial movement speed

Hefty load and long service life

Applicationgs:semiconductor equipment,tire machinery,monocrystalline silicon furnace,health-related rehabilitation products

Firm profile

HangZhou YIGONG has a complete overall performance laboratory of rolling practical components, higher-velocity ball screw pair 60m/min working sound 70dB, higher-velocity rolling linear CZPT pair 60m/min running noise 68dB, for precision horizontal machining heart batch matching ball screw pair, rolling CZPT pair, to accomplish every axis quick relocating pace 40m/min, positioning accuracy .002mm, repeated positioning precision .001mm. Our equipments import from Japan and Germany and so on.

FAQ

Why select AZI China?

With far more than 60 years of creation knowledge, good quality assurance,manufacturing facility straight price tag.

How can I get a sample to check out the top quality?

We quotation according to your drawing, the price tag is suited, sign the sample checklist.

What is your primary merchandise ?

Our Principal items are consist of ball screw,linear information,arc linear guide,ball spline and ball screw linear CZPT rail module.

| Material: | Gcr15 |

|---|---|

| Load: | Customized |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | Customized |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

###

| Samples: |

US$ 10/Set

1 Set(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Product name | Ball spline |

| Model | GJZ,GJZA,GJF,GJH,GJZG,GJFG, |

| Dia | 15mm-150mm |

| Material | Bearing Steel |

| Precision Class | Normal/ High/ Precise |

| Package | Plastic bag, box, carton |

| MOQ | 1pc |

| Material: | Gcr15 |

|---|---|

| Load: | Customized |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | Customized |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

###

| Samples: |

US$ 10/Set

1 Set(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Product name | Ball spline |

| Model | GJZ,GJZA,GJF,GJH,GJZG,GJFG, |

| Dia | 15mm-150mm |

| Material | Bearing Steel |

| Precision Class | Normal/ High/ Precise |

| Package | Plastic bag, box, carton |

| MOQ | 1pc |

The Different Types of Splines in a Splined Shaft

A splined shaft is a machine component with internal and external splines. The splines are formed in four different ways: Involute, Parallel, Serrated, and Ball. You can learn more about each type of spline in this article. When choosing a splined shaft, be sure to choose the right one for your application. Read on to learn about the different types of splines and how they affect the shaft’s performance.

Involute splines

Involute splines in a splined shaft are used to secure and extend mechanical assemblies. They are smooth, inwardly curving grooves that resist separation during operation. A shaft with involute splines is often longer than the shaft itself. This feature allows for more axial movement. This is beneficial for many applications, especially in a gearbox.

The involute spline is a shaped spline, similar to a parallel spline. It is angled and consists of teeth that create a spiral pattern that enables linear and rotatory motion. It is distinguished from other splines by the serrations on its flanks. It also has a flat top. It is a good option for couplers and other applications where angular movement is necessary.

Involute splines are also called involute teeth because of their shape. They are flat on the top and curved on the sides. These teeth can be either internal or external. As a result, involute splines provide greater surface contact, which helps reduce stress and fatigue. Regardless of the shape, involute splines are generally easy to machine and fit.

Involute splines are a type of splines that are used in splined shafts. These splines have different names, depending on their diameters. An example set of designations is for a 32-tooth male spline, a 2,500-tooth module, and a 30 degree pressure angle. An example of a female spline, a fillet root spline, is used to describe the diameter of the splined shaft.

The effective tooth thickness of splines is dependent on the number of keyways and the type of spline. Involute splines in splined shafts should be designed to engage 25 to 50 percent of the spline teeth during the coupling. Involute splines should be able to withstand the load without cracking.

Parallel splines

Parallel splines are formed on a splined shaft by putting one or more teeth into another. The male spline is positioned at the center of the female spline. The teeth of the male spline are also parallel to the shaft axis, but a common misalignment causes the splines to roll and tilt. This is common in many industrial applications, and there are a number of ways to improve the performance of splines.

Typically, parallel splines are used to reduce friction in a rotating part. The splines on a splined shaft are narrower on the end face than the interior, which makes them more prone to wear. This type of spline is used in a variety of industries, such as machinery, and it also allows for greater efficiency when transmitting torque.

Involute splines on a splined shaft are the most common. They have equally spaced teeth, and are therefore less likely to crack due to fatigue. They also tend to be easy to cut and fit. However, they are not the best type of spline. It is important to understand the difference between parallel and involute splines before deciding on which spline to use.

The difference between splined and involute splines is the size of the grooves. Involute splines are generally larger than parallel splines. These types of splines provide more torque to the gear teeth and reduce stress during operation. They are also more durable and have a longer life span. And because they are used on farm machinery, they are essential in this type of application.

Serrated splines

A Serrated Splined Shaft has several advantages. This type of shaft is highly adjustable. Its large number of teeth allows large torques, and its shorter tooth width allows for greater adjustment. These features make this type of shaft an ideal choice for applications where accuracy is critical. Listed below are some of the benefits of this type of shaft. These benefits are just a few of the advantages. Learn more about this type of shaft.

The process of hobbing is inexpensive and highly accurate. It is useful for external spline shafts, but is not suitable for internal splines. This type of process forms synchronized shapes on the shaft, reducing the manufacturing cycle and stabilizing the relative phase between spline and thread. It uses a grinding wheel to shape the shaft. CZPT Manufacturing has a large inventory of Serrated Splined Shafts.

The teeth of a Serrated Splined Shaft are designed to engage with the hub over the entire circumference of the shaft. The teeth of the shaft are spaced uniformly around the spline, creating a multiple-tooth point of contact over the entire length of the shaft. The results of these analyses are usually satisfactory. But there are some limitations. To begin with, the splines of the Serrated Splined Shaft should be chosen carefully. If the application requires large-scale analysis, it may be necessary to modify the design.

The splines of the Serrated Splined Shaft are also used for other purposes. They can be used to transmit torque to another device. They also act as an anti-rotational device and function as a linear guide. Both the design and the type of splines determine the function of the Splined Shaft. In the automobile industry, they are used in vehicles, aerospace, earth-moving machinery, and many other industries.

Ball splines

The invention relates to a ball-spinned shaft. The shaft comprises a plurality of balls that are arranged in a series and are operatively coupled to a load path section. The balls are capable of rolling endlessly along the path. This invention also relates to a ball bearing. Here, a ball bearing is one of the many types of gears. The following discussion describes the features of a ball bearing.

A ball-splined shaft assembly comprises a shaft with at least one ball-spline groove and a plurality of circumferential step grooves. The shaft is held in a first holding means that extends longitudinally and is rotatably held by a second holding means. Both the shaft and the first holding means are driven relative to one another by a first driving means. It is possible to manufacture a ball-splined shaft in a variety of ways.

A ball-splined shaft features a nut with recirculating balls. The ball-splined nut rides in these grooves to provide linear motion while preventing rotation. A splined shaft with a nut that has recirculating balls can also provide rotary motion. A ball splined shaft also has higher load capacities than a ball bushing. For these reasons, ball splines are an excellent choice for many applications.

In this invention, a pair of ball-spinned shafts are housed in a box under a carrier device 40. Each of the two shafts extends along a longitudinal line of arm 50. One end of each shaft is supported rotatably by a slide block 56. The slide block also has a support arm 58 that supports the center arm 50 in a cantilever fashion.

Sector no-go gage

A no-go gauge is a tool that checks the splined shaft for oversize. It is an effective way to determine the oversize condition of a splined shaft without removing the shaft. It measures external splines and serrations. The no-go gage is available in sizes ranging from 19mm to 130mm with a 25mm profile length.

The sector no-go gage has two groups of diametrally opposed teeth. The space between them is manufactured to a maximum space width and the tooth thickness must be within a predetermined tolerance. This gage would be out of tolerance if the splines were measured with a pin. The dimensions of this splined shaft can be found in the respective ANSI or DIN standards.

The go-no-go gage is useful for final inspection of thread pitch diameter. It is also useful for splined shafts and threaded nuts. The thread of a screw must match the contour of the go-no-go gage head to avoid a no-go condition. There is no substitute for a quality machine. It is an essential tool for any splined shaft and fastener manufacturer.

The NO-GO gage can detect changes in tooth thickness. It can be calibrated under ISO17025 standards and has many advantages over a non-go gage. It also gives a visual reference of the thickness of a splined shaft. When the teeth match, the shaft is considered ready for installation. It is a critical process. In some cases, it is impossible to determine the precise length of the shaft spline.

The 45-degree pressure angle is most commonly used for axles and torque-delivering members. This pressure angle is the most economical in terms of tool life, but the splines will not roll neatly like a 30 degree angle. The 45-degree spline is more likely to fall off larger than the other two. Oftentimes, it will also have a crowned look. The 37.5 degree pressure angle is a compromise between the other two pressure angles. It is often used when the splined shaft material is harder than usual.

editor by czh 2022-12-30

China Roller chain and sprocket manufacturer Custom belt drive bmw in Jubayl Saudi Arabia Made Tapered Roller Bearing Lm11749 10 Ball and Roller Bearing with ce certificate top quality low price

We – EPG Group the most significant Chain and agricultural gearbox factory in China with 5 various branches.

Our major goods are chain , gears, sprocket, Needle Roller bearings, Cylindrical Roller Bearings, Rod finish Bearings, Spherical plain bearings, Monitor roller Bearings for Guideway, Roller Bearings, Merge Bearings for forklifts, H2o Pump Bearings, SNR Automobile Bearings and all varieties of Spherical Bearings. industrial we have received the have confidence in of purchasers around the world. a specialized provider of a complete assortment of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….components such as roller chains. Roller chains are offered in normal, nickel plated & stainless steel resources in pitch dia. ranging from 1/4 in. to 3 in. Types contain leaf chains in lacing configurations ranging from 2 x 2 to 8 x 8. Leaf chains are accessible in pitch sizes ranging from 1/2 in. to 2 in., pin dia. ranging from .156 in. to .687 in. & tensile strengths ranging from 4,000 lbs. to 156,000 lbs. Programs consist of agricultural, conveyors, drilling, electronics assembly, meals processing, fork carry vans, hoists, packaging & textile machinery. Common solitary-strand roller chain, standardized by ASME, is an assembly of alternating pin back links and roller back links. The distance between pin centers is named the pitch. The pitch is what categorizes the dimensions of the chain. The larger the pitch, the increased the load score. Chains with little pitches have more compact loads, function more quietly, and at greater speeds. Multi-strand, little-pitch roller chains are a good answer for large-load, substantial-pace applications.

Item parameters

| Commodity | tapered roller bearings |

| Materials | Chrome steel GCR15 |

Detail:

| Inch Series Tapered Roller Bearing | |||||||

| Bearing No. | demension | ||||||

| d | D | T | B | C | R | r | |

| 11590/11520 | fifteen.875 | 42.862 | fourteen.288 | fourteen.288 | nine.525 | 1.6 | 1.six |

| LM11749/ten | seventeen.462 | 39.878 | thirteen.843 | 14.605 | ten.688 | one.2 | 1.two |

| LM11949/10 | 19.05 | forty five.237 | 15.494 | 16.637 | 12.065 | one.2 | 1.two |

| A6075/A6175 | 19.05 | forty nine.225 | 21.209 | 19.05 | 17.462 | one.two | 1.six |

| 12580/12520 | 20.638 | 49.225 | 19.845 | 19.845 | 15.875 | one.five | 1.five |

| LM12749/ten | 21.987 | 45.237 | 15.494 | 16.637 | 12.?065 | 1.2 | one.2 |

| LM12749/eleven | 21.986 | 45.794 | 15.494 | 16.637 | 12.065 | one.2 | 1.2 |

| M12649/10 | 21.forty three | fifty.005 | 17.526 | eighteen.288 | thirteen.ninety seven | one.two | one.two |

| 1280/1220 | 22.225 | 57.fifteen | 22.225 | 22.225 | 17.462 | .8 | one.six |

| 1755/1726 | 22.225 | 56.896 | 19.368 | 19.837 | 15.875 | one.two | one.2 |

| 7093/7196 | 23.812 | 50.005 | 13.495 | fourteen.26 | 9.525 | 1.5 | 1 |

| 7097/7196 | 25 | 50.005 | 13.495 | 14.26 | twelve.seven | one | one.2 |

| 7100/7204 | 25.four | fifty one.994 | fifteen.011 | fourteen.26 | 12.seven | one | 1.two |

| 1780/1729 | 25.four | 56.896 | 19.368 | 19.837 | fifteen.875 | .8 | 1.3 |

| L44643/ten | 25.four | 50.292 | 14.224 | 14.732 | ten.668 | 1.two | one.two |

| M84548/ten | 25.four | 57.15 | 19.431 | 19.431 | 14.732 | one.five | 1.5 |

| 15101/15243 | 25.4 | sixty one.912 | 19.05 | 20.638 | 14.288 | .eight | 2 |

| 7100/7196 | 25.4 | fifty.005 | 13.495 | fourteen.26 | nine.525 | one.one | one |

| 7100/7204 | twenty five.four | 51.994 | 15.011 | fourteen.26 | 12.seven | 1 | one.2 |

| 15101/15245 | 25.four | sixty two | 19.05 | twenty.638 | 14.282 | 3.6 | one.2 |

| L44649/10 | 26.988 | 50.292 | 14.224 | 14.732 | ten.668 | 3.six | one.two |

| 2474/2420 | 28.575 | sixty eight.262 | 22.225 | 22.225 | seventeen.462 | .8 | one.6 |

| 2872/2820 | 28.575 | seventy three.571 | 22.225 | 22.225 | 17.462 | .8 | 3.2 |

| 15113/15245 | 28.575 | sixty two | 19.05 | 20.638 | fourteen.288 | .8 | 1.2 |

| L45449/ten | 29 | fifty.292 | 14.224 | 14.732 | 10.668 | three.six | one.2 |

| 15116/15245 | 30.112 | sixty two | 19.05 | 20.638 | fourteen.288 | 1 | one.two |

| M86649/ten | thirty.162 | sixty four.292 | 21.432 | 31.432 | sixteen.sixty seven | 1.6 | 1.six |

| M88043/10 | 30.213 | sixty eight.262 | 22.225 | 22.225 | 17.462 | two.4 | one.six |

| LM67048/10 | 31.75 | 69.012 | 19.845 | 19.583 | 15.875 | three.five | one.3 |

| 2580/20 | 31.seventy five | sixty six.421 | twenty five.4 | twenty five.357 | 20.638 | .eight | three.two |

| 15126/15245 | 31.seventy five | 62 | 19.05 | 20.638 | 14.288 | .8 | 1.2 |

| HM88542/10 | 31.seventy five | seventy three.571 | 29.37 | 27.783 | 23.02 | one.2 | 3.2 |

| M88048/ten | 33.338 | 68.262 | 22.225 | 22.225 | seventeen.462 | .eight | one.six |

| LM48548/ten | 34.925 | sixty five.088 | 18.034 | 18.288 | 13.97 | sp | 1.2 |

| HM88649/10 | 34.925 | 72.233 | 25.four | 25.four | 19.842 | 2.four | 2.four |

| L68149/ten | 34.98 | fifty nine.131 | 15.875 | sixteen.764 | 11.938 | sp | 1.two |

| L68149/11 | 34.ninety eight | 59.975 | 15.875 | sixteen.764 | eleven.938 | sp | one.2 |

| HM88648/ten | 35.717 | 72.233 | twenty five.4 | 25.4 | 19.842 | 3.six | two.4 |

| HM89449/10 | 36.512 | 76.2 | 29.37 | 28.575 | 23.05 | 3.5 | 3.3 |

| JL69349/10 | 38 | 63 | 17 | 17 | thirteen.five | sp | sp |

| LM29748/10 | 38.one | sixty five.088 | 18.034 | 18.288 | 13.ninety seven | sp | one.2 |

| LM29749/10 | 38.1 | 65.088 | 18.034 | 18.288 | thirteen.97 | 2.three | 1.three |

| LM29749/11 | 38.1 | 65.088 | 19.812 | eighteen.288 | fifteen.748 | two.four | one.two |

| 418/414 | 38.1 | 88.501 | 26.988 | 29.083 | 22.225 | three.6 | 1.6 |

| 2788/20 | 38.1 | seventy six.2 | 23.812 | twenty five.654 | 19.05 | seventy three | ninety.five |

| 25572/25520 | 38.one | 82.931 | 23.812 | twenty five.4 | 19.05 | .8 | .eight |

| LM300849/eleven | 10.988 | 67.975 | seventeen.5 | eighteen | 13.five | sp | one.five |

| LM501349/10 | 41.275 | 73.431 | 19.558 | 19.812 | 14.732 | three.six | .eight |

| LM501349/14 | forty one.275 | 73.431 | 21.forty three | 19.812 | sixteen.604 | three.six | .eight |

| 18590/twenty | forty one.275 | eighty two.55 | 26.543 | twenty five.654 | twenty.193 | three.six | 3.2 |

| 25577/20 | 42.875 | 82.931 | 23.812 | twenty five.four | 19.05 | three.six | .eight |

| 25580/20 | forty four.45 | eighty two.931 | 23.812 | 25.4 | 19.05 | three.five | .eight |

| 17787/31 | 45.23 | 79.985 | 19.842 | 20.638 | fifteen.08 | two | one.3 |

| LM603049/eleven | 45.242 | seventy seven.788 | 19.842 | 19.842 | 15.08 | three.six | .eight |

| LM157149/ten | 45.242 | seventy three.431 | 19.558 | 19.812 | 15.748 | three.6 | .8 |

| 25590/20 | forty five.618 | eighty two.931 | 23.812 | 25.4 | 19.05 | 3.five | .8 |

| LM503349/10 | forty five.987 | seventy four.976 | eighteen | eighteen | 14 | two.four | one.six |

| JLM104948/ten | fifty | eighty two | 21.501 | 12.501 | 17 | 3 | .five |

| LM10949/11 | fifty.eight | eighty two.55 | 21.fifty nine | 22.225 | 16.5 | three.6 | 1.two |

| 28KW01G | 28 | 50.292 | 14.224 | sixteen.667 | 10.7 | two | 1.three |

| 28KW02G | 28 | fifty two | fifteen.eight | 18.five | twelve | 2 | 1.three |

| 28KW04G | 28 | 50.292 | fourteen | eighteen.sixty five | ten.668 | 2 | 1.three |

| 31KW01 | 31.75 | fifty three.975 | fifteen.3 | fourteen.nine | eleven.nine | 2 | 1.3 |

Item Description

Description of the bearing

Spherical roller bearing are two internal ring raceway,outer ring raceway spherical roller bearing kind.The outer ring raceway centre regular with the bearing heart,it has a self-aligning houses,can instantly adju EPT because of to installation mistake or shaft deflection arising among the eccentric shaft and the bearing,the outer ring and the inner ring relative to the centerline of not much more than 1-2.5,the bearing can still perform appropriately.Can bear radial load and axial load,specifically for weighty responsibility and shock loads.

PRODUCT DETAILS

The interior and outer ring raceways and rollers of the tapered roller bearing are made with a taper so that the floor planes of the raceways and roller axis meet at a level. The rollers are guided by a flange on the interior ring.Outer ring, interior ring and roller assembly. The non-separable inner ring and roller assembly is named the “cone”, and the outer ring is referred to as the “cup”. Inside clearance is set up for the duration of mounting by the axial position of the cone relative to the cup.

Our firm

In 2006, David Ding graduated from college and entered the bearing organization at the age of 22. He commenced from the bearing generation, analyzed the bearing production approach and technological innovation, then transferred to the company’s product sales office, created the global marketplace, served consumers from all over the globe and domestic investing companies, and was unanimously acknowledged and praised by consumers.

Starting from “zero”, in buy to supply greater and adaptable providers to customers, HangZhou Primary Seiko Parts (bearing) Co., Ltd. was started, which is found in HangZhou, ZheJiang Province, the entire world bearing distribution heart, with special geographical rewards. Relying on the benefits of regional industrial chain, we can make high performance bearing goods with skilled technological innovation. At the very same time, by way of a lot more than 10 many years of accumulation and summary, we can provide the mo EPT expert financial bearing options for international customers and domestic exporting firms.

Our company mainly makes automotive bearings, which includes automotive wheel hub bearings (device), automotive clutch release bearings, automotive tensioner & idler bearings, wheel bearing repair kits and automotive generator bearings.They are largely appropriate for Toyota, Mitsubishi, Nissan, Isuzu, Mazda, Daewoo, Kia, Hyundai, Volkswagen, Audi, Mercedes Benz, BMW, Ford, GM, Volvo and EPT types. Also we an can make OEM in accordance with customers’ samples or drawings. Now our merchandise are primarily exported to Middle East, Central Asia, Southea EPT Asia, South America, Africa, Russia, Europe and EPT international locations and regions. The estimated turnover in 2571 is more than 5 million US dollars.

We have the import and export correct, with SGS certification and produced-in-china area certification ! we are Audited Supplier of MIC. The unbiased model “RIME MAX” car bearings is really well-liked all over the planet. Our organization tenet is “serving clients with entire heart”.”Enable client satisfied is our final aim”. Our perform philosophy is “detai EPT figure out accomplishment or failure and attitude establishes every little thing!”

David Ding, 36 years previous in 2571, hopes that we can recognize our aspiration jointly! Win the potential with our specialist services!

Detection stage

Factory tour

Our services

Packaging & transportation

A1: Plastic paper + kraft paper + outer carton + Nylon bag

A2: Tube package deal + outer carton + Nylon bag

A3: Single box+outer carton+pallets

A4: According to your need.

FAQ

1. Item packaging?

Single carton carton picket pallet

two .The manufacturing cycle of the item?

Place specific 1 day

Normal goods 7-thirty days

Customized goods 30-40 days

3.Product lead time?

3-20 days with much less amount

Large number of 30-forty five times

4What is the main market place?

Europe South The united states Center Ea EPT Africa

5 What are our rewards?

Fantastic services!

Answer speedily!

Actual item pictures!

Develop potential with provider!

The use of unique equipment manufacturer’s (OEM) part quantities or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our firm and the outlined substitute areas contained herein are not sponsored, accepted, or produced by the OEM.