Set up of sprockets

For smooth transmission and extended life with the roller chain, it is actually important to properly set up right sprockets. Use the following set up method.

one.Correctly set up a sprocket on a shaft, and repair it with a vital to prevent it from rattling during operation. Also, area the sprocket as close as you possibly can to the bearing.

2.Change the shaft levelness to ?¨¤1/300 or significantly less utilizing a level.

three.Adjust the shaft parallelism[(A¡ê-B)/L]to ?¨¤1/300 or much less.

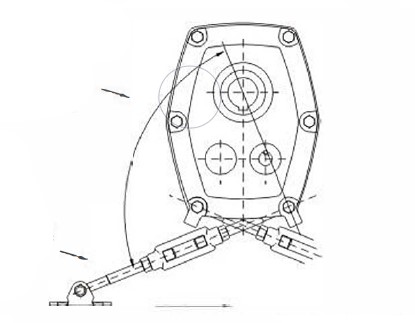

4.Alter the level of driving and driven sprockets utilizing a linear scale. (Also adjust the idler as well as sprockets, or even the tensioner and also the sprockets in the very same way.)

Maintain the allowance |? inside the selection specified.

Set up of roller chain

When connecting a roller chain together with the sprockets, observe the following procedure. Once the connecting hyperlink will not be well lubricated, apply ample grease.

When making use of the sprocket teeth

one. Engage the chain using the sprockets  to ensure that the two ends of your chain are on among the list of sprockets, as shown within the following photo.

to ensure that the two ends of your chain are on among the list of sprockets, as shown within the following photo.

2. Insert connecting pins in the joint.

3. Match a connecting plate, and fasten by a spring clip or cotters.

Pay further attention to not damage the tooth heads from the sprocket.

When utilizing tools

Cautions

one.When a connecting plate is fastened by a spring clip,apply the spring clip on the pin grooves in the connecting pins as illustrated beneath, and lock it utilizing pliers, and so on. As for your direction of spring clip insertion, preserve the opening with the spring clip turned inside the path opposite to the course of chain rotation, as illustrated beneath.

two.In circumstances exactly where the sprocket center distance can hardly be adjusted, an odd amount of hyperlinks may be used. Even so, add 1 link, to utilize an even quantity of back links and eradicate the sag by shifting a sprocket or putting in an idler.

When an H-connecting website link is made use of, pins must be driven into the connecting plate since of interference. In this instance, be sure that the pair of pins are kept parallel to every other when inserted into the connecting plate. Under no circumstances make the holes of your connecting plate bigger or make the pins thinner for much easier connection work. This applies also when a cotter form outer hyperlink (CP) is utilised as an alternative to a connecting hyperlink.