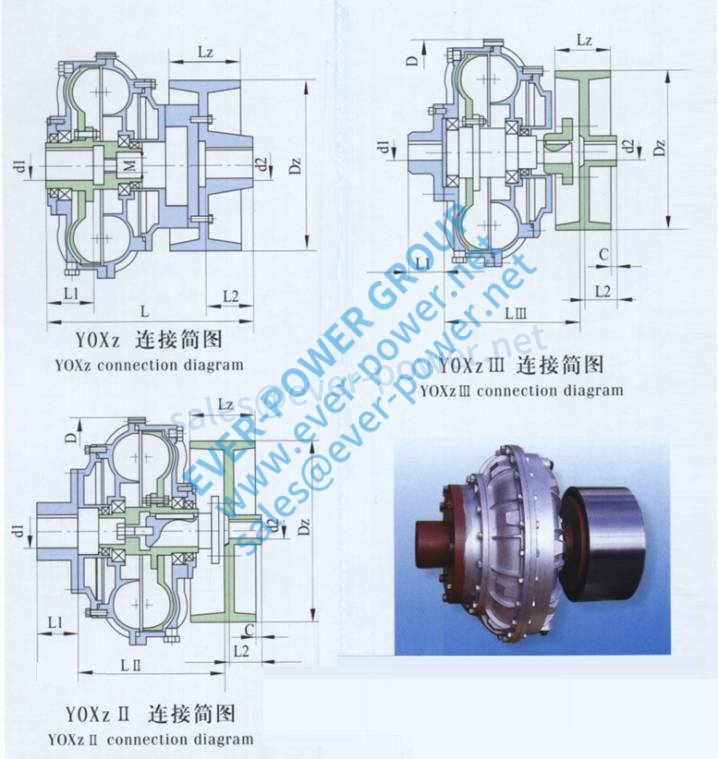

fluid coupling

Inexpensive soft begins, with clean acceleration

Shock- load security

Fluid Couplings

Variety HF25 Disc Coupling Mount

From underground & overland belt conveyors to crusher and mixing purposes, equipment experts are consistently seeking greater technologies to safeguard essential creation techniques towards the consequences of detrimental shock loads. And when it will come to eliminating sudden/ jarring starts, or stopping program failure/ deterioration owing to overloads, nothing outperforms the system- saving capacity of Falk Accurate Torque fluid couplings.

Unmatched, cushioned comfortable commence adaptability, at an affordable value point.

Sleek acceleration.

Mechanical overload security.

NEW dimensions 2760HF & 2870HF offer higher ability at increased speeds.

Elevated commencing torque accessible from normal NEMA B motors

with a fluid coupling. This is a reward not offered by electronic gentle commence remedies.

Offering the softest, smoothest begin will optimize the daily life of your method parts.

As the wise option to high-priced & complicated electronic solutions, Falk True Torque⢠fluid couplings let specific adjustment of startup attributes in the discipline, basically by shifting the fluid fill level via the easy access fill & drain holes.

fluid coupling cross-section

NEW Longer commencing profiles and  softer commences.

softer commences.

For Sizes 1420HF & greater, adjustable metering orifices control the passage of fluid from the hold off fill chamber into the functioning circuit,  additional softening the begin.

additional softening the begin.

For advanced belt conveyors, think about Sort HFDD. The extended delay fill chamber permits preliminary start off factor as low as 40% of the complete load torque, drastically decreasi ng shock & extend to the belt at startup.

ng shock & extend to the belt at startup.

fluid coupling cross-section

Use of the prolonged hold off fill chamber (HFDD) is suggested for conveyors subjected to unloaded begins, people with concave sections, these with reduced inertia, or individuals with any blend of these circumstances. Modest fill in the functioning circuit at startup minimizes belt liftoff, and assures unloaded & low inertia conveyors are not rapidly accelerated. Defense â no matter of load issue.