Having accumulated precious experience in cooperating with foreign customers, a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Construction works , Energy & Mining, agricultural machiner

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Product Name:

-

Module 06 spur gear manufacturing

- Mod.(Standard):

-

Module 1, 1.5,2,2.5 ,03 ,4,5,6,7,8

- Nonstandard:

-

According to customers’ drawing

- Surface treatment:

-

Black oxide,Zinc plated

- Processing:

-

CNC Machining

Supply Ability

- Supply Ability:

- 7000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Carton box,Wooden packing or according to customers’ requirements

- Port

- Tianjin

-

Lead Time

: -

Quantity(Bags) 1 – 50 >50 Est. Time(days) 10 To be negotiated

Online Customization

EPG – one of the biggest transmisison suppliers in China. Every process, every section, every function in EPG is demanded to be done one step following another, carefully and cautiously, from material selection, reformation to manufacturing accessories, from components heat treatment to automatic assembly, from quality control to product inspection and testing and from order dealing to after sales service.”We are always serving our customers with our best products.” EPG will always adhere to it enterprise spirit of being practical, innovative, efficient and excellent to make the top international transmission drive.

Product Description

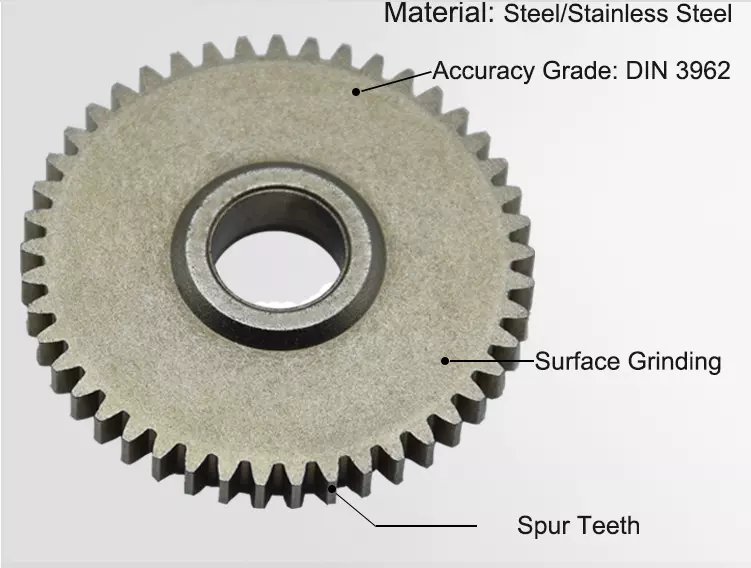

Module 06 spur gear manufacturing

FUTURE SUCCESS BELONGS TO QUALITY LEADER!

BUILDING BRAND ON QUALITY!

|

Product name |

Module 06 spur gear manufacturing |

||

|

Item |

M0.–Driven (outer) yoke same as drive yoke but is mounted on the implement. There are two types of shafts, domestic and metric, which are identifiable by their shapes. Domestic are generally one of four shapes: round, square, rectangle or splined. Metric are: bell, star or football shaped. In either case the primary (front) shaft is the same shape as the secondary shaft, only bigger so that the secondary shaft fits inside. This allows a telescoping effect to take place when the implement is raised on the 3 pt. or during a turning movement such as a bailer. All shafts have to be sized before use. Attach the implement to the 3 pt. and raise and support it. Attach the proper end to the tractor and attempt to attach the other to the implement. If the shaft is too long trim one of the shafts with a hack saw and try it again until it fits. This allows for the implement to be raised without binding. The shafts should overlap as much as allowed.5,M1,M1.5,M1.7,M2,M2.5,M3,M4,M5,M6 and so on |

||

|

Standard |

European or American standard |

||

|

Material |

carbon steel such as C45, 20CrMnTi, 40Cr, 42CrMo or stainless steel or copper, brass or nylon etc. |

||

|

Heat Treatment |

Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on |

||

|

OEM service |

make based on your special sample or drawing and meet your need for high precision on teeth of gear |

||

HRSY Spur Gear Catalogue

Please choose your module number, please contact us to get more catalogue.

Our Company

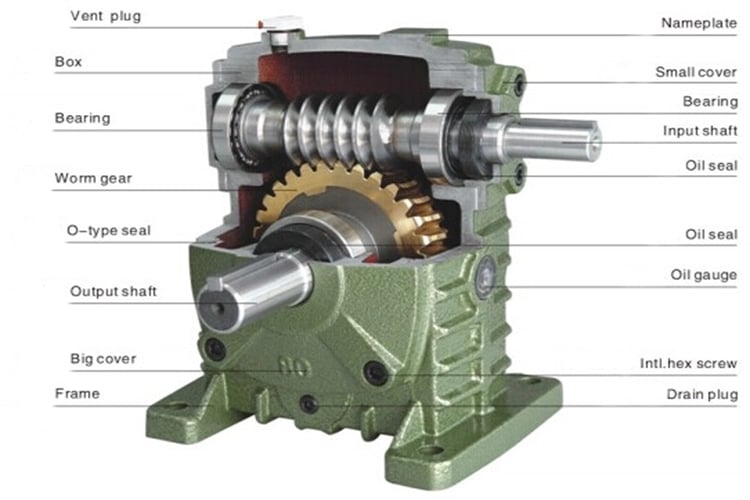

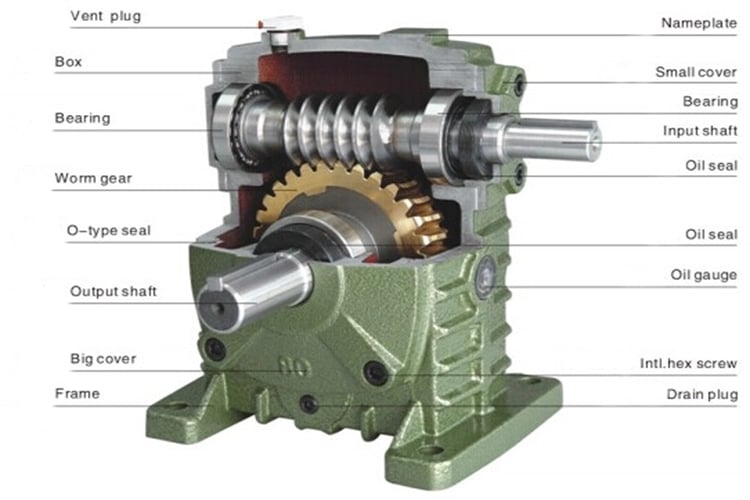

HangZhou EGP Electrical Equipment Co.,Ltd was founded in HangZhou in 1997 and is a professional manufacturer and exporter that is concerned with the design, development and production.With detailed requirments, we can also develop your special designed product. Our Machining of the gearbox To make a worm gearbox, first take a blank of an alloy. A bronze bearing is made in the center of the blank. The hobbing cutter is then used to reduce the diameter of the blank relative to the finished height of the tooth tip on the gear wheel, so the depth of the cut needs to be added to the blank’s diameter. The necessary threading tool is grind to cut the worm. The side clearance on the left-hand side of the cutter tip is allowed for the worm’s pitch angle. The best finish is put on the cutting tool using a slip stone. Gear blank is then mounted on a turntable that acts as a bearing support. This bearing support is mounted on the rear of the lathe cross-slide with the hobbing cutter mounted between the centers. The two worms are then machined, out of which one is made the cutter and finally the cutter is used to machine the worm gear.product range includes all kinds of Timing pulley,helical gear, spur gear, bevel gear, gear rack, worm gear, sprockets,Motorcycle sprockets and chains

· Our Principle: “Credibility Supremacy, and Customer First”

· Our Promise: “High quality products, and Excellent Service”

· Our Value: “Being Honesty, Doing the Best, and Long-lasting Development”

· Our Aim: “Develop to be a leader in the power transmission parts industry in the world”

Packing & Delivery

———————————————— packaging ————————————–

—————————————– SHIPMENT ————————————–

Whether you have your own freight-forward or you would like us to arrange the shipment.

Whether you require delivery FOB to a port in China Or CIF to a port near you, we are happy to quote and supply whichever may you choose. Please feel free to let me know your option.

Our Service

OUR SERVICES

1) Quality & Service:We take care of the product quality in order to provide good service to our customers.

2) Price:In order to serve better to our customer we are always finding the way to reduce the price.

3) Special Service:In this competitive world we always provide a promotion offers to our customer so our customer can able to save a good amount.

OUR ADVANTAGES

1) MOQ:We can supply you the quantity you want.

2) OEM:We can produce the goods as per the customer requirement.

3) Service:We are much more concern for the ON TIME DELIVERY & QUALITY.

WE PROVIDE THE FOLLOWING SERVICE AFTER RECEIVING YOUR ORDER:

1) During the production we arrange the samples lot as per the customer requirement, then we send the samples photo and samples to the customer to approval.

2) After the production finish we send the samples to customer to check, after customer approval we ship the goods to the customer.

3) After customer received the goods we check and take the necessary follow-up with the customer in order to solve some small mistakes inAdhering to “Survival by Quality, Development by Technology & Credit”, The company will constantly improve product performance to meet the increasing customer requirements in the rigorous style of work. next lot.

HRSY Main Products

Industrial Sprocket

Motorcycle Sprocket

Roller Chain

Spur Gear

Helical Gear

Bevel Gear

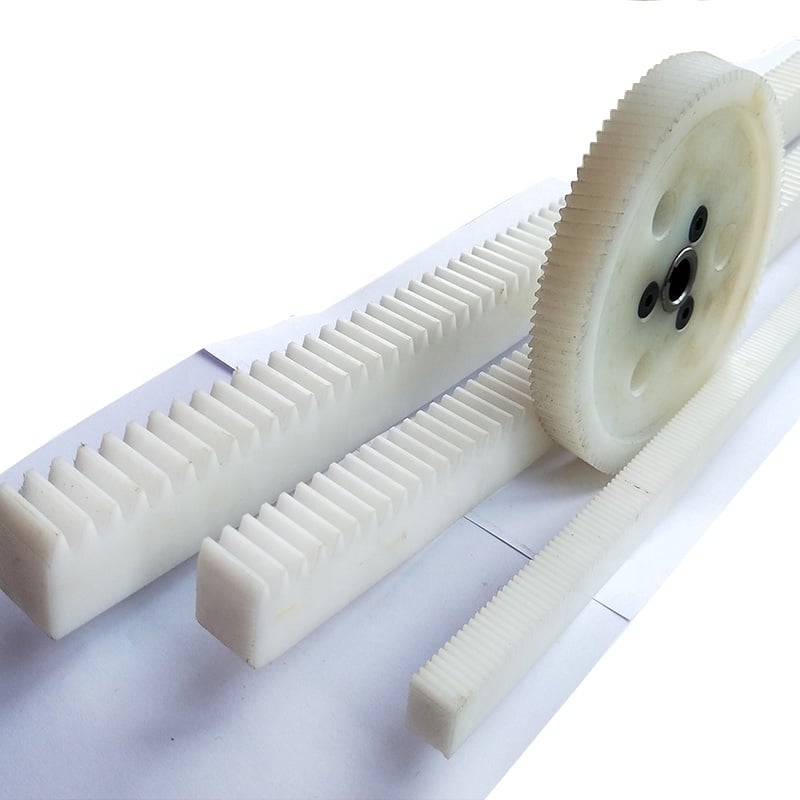

Plastic/POM/Nylon Gear

Small Pinion Gear

Worm Gear and shaft

Gear Rack

Timing Pulley

Taper Bushing

Chain Guides

Linear Rail and Block

Ball Screw

Contact Information