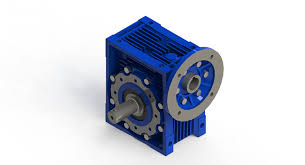

Worm drive gearbox with motor

worm motor

A robust worm-drive gearbox powered by an MM28 engine. Ideal applications where an easy to match, high torque end result is required. Great for student based jobs which includes robots and buggies.

The unit has been designed to ensure that the output shaft can be ‘clicked’ in and out for modification. Electronic.g. reducing to size. The electric motor is snap fitted into its cradle to engage the gear and worm.

Details

1 – 6V DC

0.1A to 1A depending on load

Driveshaft length: 12.5cm

Driveshaft diameter 3mm

Gearbox ratio: 42:1

General dimensions of box + electric motor: 35(W) x 40(H) x 60(L)mm

The primary feature of the high-efficiency gear box is a worm gear, which locks the output shaft whenever the motor is not turning. The high gear ratios of 216:1 or 336:1 make this gearbox appropriate for small strolling robots, lifting mechanisms, and various other applications where high torque is desired.

The low-voltage motors in the worm gearbox operate on 1.5-4.5 volts and draft to some amps, making them perfect candidates for the DRV8833 motor driver carrier. Engine overheating can be caused by excessive stalling, also at suprisingly low voltages. We advise that you utilize stall-detection sensors, or just view your robot, to ensure that it doesn’t stall for more than a few seconds at a time.

This gearbox includes a 4 mm diameter, round output shaft, which works with the wheels that are compatible with Tamiya 4 mm, round shafts. Our 3 mm universal mounting hub also matches on small threaded end of the shaft, although it is not particularly designed to work with this type of shaft (the hub’s set screw could harm the thread on the shaft).

Ever-Power gear motors will be economical, right-angle, worm-geared motors that install easily found in the tightest applications. Economical right position worm geared motors set new requirements for reliability, efficiency and economic climate with unparalleled features including hollow shafts in the tiniest sizes. An inverter friendly design offers easy integration today and a future proof alternative. The Ever-Power gear motor offers total flexibility in mounting choices includes shaft, base, encounter, and flange alternatives. The motor terminal box can be mounted in substitute positions rotated in 90º steps around the electric motor frame providing for unparalleled integration options.

Ever-Power gear motors adhere to North American and International criteria, including NEMA, IEC, CSA, and CE, the Ever-Power series allows for worldwide acceptance, a true total answer for our global customers.

Superior protection of IP65 acc. to IEC 529 assures you that the Ever-Power series is dust tight and hose proof,and can be used outside or in wet and dusty environments without the use of additional enclosures. Complete rated output is available at the output shaft of the unit.

Product Features

Power ranking up to 5,5 kW.

Torque 25 … 1.000 Nm

Output Speeds 0,2 … 300 min-1

versatile installation possibilities

Completely enclosed, sealed against dust and water spray

Lubrication change initial after 15000 hrs

Low noise gearing

Mains connection 110 … 690V, 50/60Hz

Enclosure IP65 (Regular), IP66 (Optional)

Additional features:

Connecting with Connect connectors.

With integrated inverter up to 7,5kW.

Ever-Power-Mark

CSA, UL, ATEX, GOST, CCC, ISO9001, ISO14001, OHSAS18001

Motors according to Sobre 60034

Corrosion category based on DIN ISO 12944-5

C1, C2, C3, C4, C5-I, C5-M

DC WORM GEAR MOTORS

Ever-Power DC worm equipment motors are the option for applications requiring a corner turn, optional dual output, or an inability for the electric motor to be back again driven. The DC right angle equipment motors are designed for constant and intermittent duty operation. Our right angle gear reducers were created with a number of mounting plate options, making them ideal for a number of DC engine based applications. We offer 12 ratios which range from 5:1 to 100:1.

10309

FEATURES

1/43 to 3/8 HP

12, 24, 90, 130, 180 VDC, 115 FWR

9 – 475 RPM

1.5 – 315.9 in-lb rated torque

Frame Size 60, 80, 108 mm

5:1 – 100:1 standard ratios

Regular brush life of 2000+ hours (varies by application)

EP Products Worm Equipment Motors are designed to generate high torque in a little package size. Worm Equipment Motors are excellent for applications that want a self- locking or breaking characteristic since the output shaft can’t rotate when there’s no power used. Additionally, Worm Gearheads can transfer movement in 90 degrees. With various decrease ratios, precision slice gears, voltages and sizes, EP Products has a DC Worm Equipment Motor solution for the application.

Features and Benefits

HIGH Torque Capabilities

Self-Locking / Braking Features

Motion Transfer of 90 Degrees

Capability to Handle Large Equipment Reduction Ratios

High Durability

Low Noise

Flexible Configuration

Applications

Security Door Locks / Industrial Conveying Systems / Security Gates / Dental care Chairs / Ambulance Cots & Stretchers Quite a few DC Motors can be complimented with among our Worm Gearheads. EP Items will continue to work with you to create and manufacture a Worm Gear Engine that will optimize the functionality of your unique application.

Built to your unique requirements

Electric motor Type: Brushed / Brushless / Coreless

Voltage

Output Speed

Power

Current

Torque

Reduction Ratio

Shaft Material & Size

Gear Material

Shaft Configuration: (D Slash / Round / Splined / Other)

General Size Parameters (L, W, H)

Encoder Type: Optical / Hall Effect

Extra Assembly Requirements (lead wires, connectors, etc.)

INTRODUCTION

The turbo metal gear worm motor runs on the metal gear box for strength and a higher torque output. Due to the special mechanical framework of the worm drive the engine output shaft can be self locking and may not be rotated.

This part runs on the two wire connection and supports direction control and also PWM speed control. Ranked voltage is 12v and will obtain 40RPM, with a torque of 8kg/cm.

SPECIFICATION

Operating Voltage: 6 – 15 V

Rated Voltage: 12V

No-load Speed: 40 RPM

No-load Current: 35 mA

Rated Torque: 32 RPM

Rated Current: 180 mA

Ranked Torque: 2.2 kg.cm

Rated Power: 1.1 W

Stall Torque: 8 kg/cm

Stall Current: 1 A

Reduction Ratio: 1:150

Weight: 167 g

EP Geared Motors with Worm Gearing – Modual & Customizable drive technology

Worm gear products from EP DRIVESYSTEMS especially display their power in applications where large gear ratios are essential. Our worm geared motors are consequently optimally suited for use in intralogistics, packaging technology and the meals & beverage industry.

Four great known reasons for EP worm geared motors:

Rugged

Our worm geared motors have a higher overload capacity

Maintenance Friendly

Washdown versions enable simple and efficient cleaning of the travel system.

Corrosion protection

The NSD tupH sealed surface area conversion is exceptionally chemical substance, corrosion and abrasion resistant.

Flexibility

Our modular design give users maximum freedom.

The modular system for optimum flexibility: Our EP worm gear units

There are numerous applications that want drive systems, and each of these has its own unique requirements. The EP series worm equipment motors can be quickly and efficiently adapted to satisfy your needs.

Worm gear units impress with their superior power density and small style. If required, we can also source them with the impressive nsd tupH surface area treatment.

In addition to the basic EP housing, you can expect an extensive line of bolt-on elements to customize the merchandise including torque arms, shaft covers and output flanges. These could be easily field set up, but we will also be happy to assemble the average person components for you.

Find out more about our modular SI worm geared motors!

Find out more

Smooth and Tidy: The EP worm gear unit SMI

SMI worm gear systems feature a soft, corrosion-resistant alluminum alloy housing. Optional nsd tupH surface area conversion makes the product ideally suited for severe and demanding industries like meals processing and pharmaceuticals.

Adaptable input designs such as NEMA, IEC or immediate motor mounts in additional foot or flange mounted casing designs.

Worm geared motors

Worm geared motors for small power range.

The WATT small worm gear unit adapt themselves concerning UNIBLOCK design optimally in the geared motor program. The units possess on all sides different repairing possibilities and enable an easy assembling for the customer.

Additional drive configurationscan be created by use of built-on add-ons (e.g. torque arm and output flanges). The housings are created in light weight structure out of aluminium die cast. Electric motor attachment is realised in general by way of IEC adapter B5 or B14A.

Technical Data

Number of sizes:5

Power Range:0.12 – 2.2kW

Output torque range:17 – 230Nm

Ratio:5 – 100

Output option:output shaft, output shaft on both sides, hollow shaft, hollow shaft with shrink disc

Assembly/installation:uniblock, flange, torque arm

Buy Worm Get Gearbox with Engine – incorporating the following features: 1 to 6V voltage rating, 17100 rpm no load velocity, 220g-cm stall torque, 3mm shaft diameter, 60mm long, 35mm huge, 40mm high, a good robust worm drive gearbox powered by an MM28 electric motor (included), most ideal for applications where a simple to fit, high torque result is required, nylon housing and gear, requires light oil or perhaps silicon grease lubrication, well suited for student based tasks including robots and buggies.

Most ideal for applications where an easy to fit, high torque outcome is required

Ideal for student based projects including robots and buggies

Reversible Excessive torque Turbo Worm Gear Engine JGY370 DC 12V 40RPM

Reversible High torque Turbo Worm Gear Engine JGY370 DC 12V 40RPM

Features:

The electric motor is Gear DC electric motor with micro-turbine worm, you can change the wiring-connection to improve motor rotation.

Turbo worm geared electric motor with self-lock, that is, regarding motor without electric, the outcome axis is fixed, self-lock.

The reducer output shaft arranged vertically with the engine shaft, whole motor output shaft relatively-short than general gear engine, widely used to be installed the dimensions requirements strictly occasion.

Specifications:

Model: JGY370

Voltage: DC12V

No load speed: 40r/min

Result torque: 5.6kg.cm

Rated current: 0.06A

Weight: 163g

Application: open the windows, door, Mini winch. Ect.

In sumo robot or combat robot competition where great holding torque’s engine is essential in order to avoid your robot being pushed by your opponent robot. The worm equipment is definitely a much better option when compared to spur gear motor. Why is worm gear so unique? Take a look wiki out: Worm Travel.

“Unlike with ordinary equipment trains, the direction of transmission (input shaft vs result shaft) isn’t reversible when using large reduction ratios, because of the increased friction involved between the worm and worm-wheel, when usually an individual start (1 spiral) worm is used. This can be an advantage when it is desired to get rid of any possibility of the output driving the input.”

In other terms, it is tough to push your load (example, your robot) if the motor is not power or rotate.

Features and Spec:

Metal gear box

Output shaft is self-locking because of the worm gear’s characteristic

Rated voltage: 12V DC

Rated output speed: 150 RPM

Rated output torque: 117mN.m (1.2kgf.cm)

Stalled torque: 196mN.m (2kgf.cm)

No load current: 60mA

Stalled current: 1.8A

Output shaft diameter: 6mm with 4.5mm slot

Weight: 150g

Monthly Archives: March 2020

worm wheel gearbox

Our gear manufacturing locations have over twenty years of worm gear style knowledge, gained through many projects that included varied sizes of custom worm gears to print  requirements.

requirements.

Being a gearing producer to Automotive level businesses, with a diverse way to obtain material types, allow us to achieve the most challenging project requirements. The mixture of robust materials, advanced manufacturer systems, reliability and our commitment to customer satisfaction makes us a top provider in advanced gearing and shafting items.

Also, we take pride in our equipment; few manufacturers have the gear to engineer steel parts as exact as we do. Even fewer manufacturing companies have the machining equipment to check the tolerances we can hold.

Focused on excellence, our employees have the most crucial priority satisfying your equipment building needs and item improvement.

The angle isn’t deep enough on the worm, so when the apparatus attempts to rotate the worm, high frictional pressure between worm shaft and gear parts keep the zone stuck constantly in place.

What’s the reason behind this inability to rotate the gear-worm?

Perspective our on the internet worm wheel gearbox gallery.

worm reduction

worm reduction

Our standard 700 Series – the heart of EP speed reducer products – has been serving industry reliably for over 10 years. Its proven modular design has set the sector standard for performance and is the most imitated product in today’s worm gear swiftness reducer marketplace. But why settle for a knock-off when you can have the initial – from EP.

Specifications

11 basic one reduction sizes

8 basic dual reduction sizes

1/6 – 25 HP

5:1 – 100:1 ratios  single reduction

single reduction

100:1 – 3600:1 ratios double reduction

Non-flanged, NEMA C-face quill, and coupled input styles

Projecting and hollow result shafts

Projecting diameters from 1/2″ to 2-1/4″

Hollow result bore diameters from 5/8″ to 3-7/16″ (with over 20 bore sizes in share)

Product Features

The 700 Series’ large oil reservoir provides efficient heat dissipation and lubrication for longer operating life.

Its multi-position mounting flexibility permits installation in virtually any position.

Housings are straddle-milled, top and bottom level, for precise alignment of horizontal and vertical bases.

Internal baffles assure positive, leak-free venting.

The 700 Series’ rugged casing, fabricated of fine-grained, gear-quality cast iron, provides optimum strength for optimum durability, in addition to greater precision during worm and gear alignment.

EP 700 Series high-strength bronze worm equipment is straddle mounted between heavy-duty tapered roller bearings to improve thrust and overhung load capacities, sizes 713-760.

Our 700 Series’ high-strength steel result shaft assures convenience of large torque and overhung loads.

Pipe plugs allow convenient fill, level, and drain in almost any mounting position.

The 700 Series’ super-finished oil-seal diameters on both input and output shafts extend seal life.

Both 2D and 3D CAD drawings are available in our eCatalog.

EP worm gearboxes possess earned a popularity to be a business benchmark worldwide. Our success came from our relentless drive for quality with state-of-the-art technology, all while offering worm gearboxes happen to be affordable prices. High flexibility accorded through a broad choice of mounting choices, shaft configurations and electric motor interfaces, creates the EP worm gearbox the default choice for the industry. The helical-worm and the double-worm version, with or without the torque limiter, soon add up to the advantage, creating an extremely versatile drive system.

EP Worm gearboxes provide great torque with low rate gear ratio. Being simple and compact in design, these gears can perform higher gear ratio than the helical gears. These worm reduction gears having screw type qualities act like helical gears, but its helix angle is typically comparatively larger) and its body is generally quite long in the axial path. The gears in these gearboxes could be right or left-handed dependant on the purpose.

Mounting option include universal housing, side flanges, foot (horizontal and vertical), shaft mounted with torque arm. Available in Solid shafts (solitary or double), with torque arm or torque limiter.

Worm reduction gears features

Principles

A worm gear is a type of interlocking gear composed of a good worm shaft and worm wheel. The worm is definitely shaped such as a screw and the worm wheel is usually a kind of gear machined to have got a tooth account with the same configuration.

The procedure of a worm gear is similar with that of a bolt and nut. The principle is the same as a nut that is fixed to ensure that it cannot rotate and for that reason progresses in the axial direction when the bolt is turned.

The look of a worm gear is considered through the relationship between the rack and spur gear on the center plane of the worm wheel.

Features

Huge reduction ratio One rotation of the worm rotates the worm wheel by one tooth. For this reason, in a 1 speed reduction gears, the wheel could be manufactured consequently that it’ll be rotated 1/60 (1/120 in particular applications).

Orthogonal shaft The shafts are aligned orthogonally because of the structure. This characteristic makes it possible to layout the turning transmitting direction at a right angle.

The arbitrariness of the rotation direction The screw direction of the worm can be clockwise or counterclockwise (generally clockwise). You’ll be able to modification the rotation path of the worm wheel by changing the screw direction.

A multitude of shaft layouts The wide variety of shaft layouts is one of the top features of interlocking gears.For instance, right shaft output, remaining shaft output, dual shaft input and dual shaft output, etc., incorporate for a total of 14 types (Number 2) and, if attachment orientations are included, you’ll be able to pick from over 40 layouts.

Low noise, low vibration The interlocking of the worm and worm wheel is definitely characteristic since the contact is linear and the relative slide is great. In comparison to rolling power transmission, sound and vibration are extremely low. Because of this, this technology is used to drive medical tools, elevators and escalators, etc.

The primary specifications of worm reduction gears

MA Series(Small)

Center distance(mm) 32,40

Reduction ratio 10,20,30,40,50,60

Input capacity(kW) 0.1~1(at an input of 1800 rpm)

Output torque(N・m) 20~66

Input speed(rpm) 0~1800

MA Series(Medium)

Center distance(mm) 50,63,80,100,125,140,160

Reduction ratio 10,15,20,25,30,40,50,60

Input capacity(kW) 0.4~30(at an input of 1800 rpm)

Output torque(N・m) 900~3570

Input speed(rpm) 0~1800

S Series

Center distance(mm) 50,60,70,80,100,120,135,155,175,200,225,250,300,350,400,450,500

Reduction ratio 10,15,20,25,30,40,50,60

Input capacity(kW) 0.3~255(at an input of 1800 rpm)

Output torque(N・m) 50~56600

Input speed(rpm) 0~1800

Key points when selecting a worm reduction gears

Selection

When choosing a worm reduction gears, the procedures for selecting the correct gear are described in the maker catalogs and the series and models ought to be selected according to those procedures. Particular care ought to be taken in crucial areas such as for example selecting the strain index, calculating the overhang load and examining heat rated potential from the manufacturer.

Cautions during use

When utilizing a worm reduction gears, the heat produced through the initial amount of use is large and running-in operation at 1/4, 1/2 and 3/4 of rated torque for eight hour periods is paramount to sufficiently achieving the performance of the worm reduction gears.

Maintenance and inspection

After completing running-in operation (approximately 50 hours), it’s important to improve the lubricating oil and to change the lubricating oil after that about 1 time per year according to the procedure manual presented by the manufacturer.

Product Description

The Worm Decrease Gear Box is supplied by our company is of high-quality. Our products are made through the use of premium quality materials and advance technology at our vendors end. They are widely used in a variety of sectors. Our goods are often available at an extremely low market prices.

Motor Mount Frame Options

TEC Motors, worm decrease gearbox.

Option A-160 B5 Framework, Flange Mount.

Option B-132 B14 Frame, Face Mount.

Option C-100/112 B5 Frame, Flange Mount.

High efficiency and secure operation. High load capability and overload functions. Result Torque = (Ability (kW) x 9550 (Regular))/ Gearbox result speed (rpm).

Higher ratios available on request reliant on service factor (40:1, 50:1, 60:1, 80:1, 100:1)

DESCRIPTION

Wormgears of the VF series are actually milestones for the market worldwide. They succeeded in combining uncompromising top quality with stateoftheart technology amd renown price effectiveness.Absolute flexibility is distributed by the wide choice of several installation options, shaft configurations and engine interface, all offered as regular. The helicalworm and the doubleworm edition, with or without the torque limiter, also accumulate, creating an extremely versatile drive system.

ADDITIONAL INFORMATION

AMP

0.42 A

EFFICIENCY

84%

HP

0.12

KW

0.09

RATIO

7

RPM

200

TEMPERATURE RATING

20 level C TO 80 level C

TORQUE

4 Nm

HSN

8483.40.00

WARRANTY PERIOD

12 Months

The worm reduction gears can be found in two series: X and H.

The series X, featuring a worm and worm wheel set, comes in versions XA with shaft and XF-XC with mounting provisions for motor.

Version XF (bell housing + coupling) offers great versatility to suit a broad range of applications and higher efficiency compared to the compact collection XC, where the emphasis is on space effectiveness.

Series H supplies the same features because series X with an added plus: a spur gear pre-stage at the input end provides higher performance and a good broader selection of ratios than the X series.

Frame sizes 110 and 90 include a cast-iron casing cast enbloc, whereas smaller sizes make use of die-cast aluminium housings. The worm shaft is manufactured from casehardened and hardened alloy metal and ground-finished.

The worm wheel includes a cast iron hub with cast bronze insert. Hollow result shaft is supplied as standard.

Broad range of possibilities:

second input, result flange, single or dual extension result shaft, torque limiter with through cable, torque arm.

small worm gearbox

Small Precison Worm Decrease Gearboxes

There are many of specifications you will need to consider when coming up with a worm gearbox selection.

First, what is the input and output torque requirements? Next, check vendor horsepower/torque charts and pick the correct worm gear reducer.

If how big is the gearbox is going to be an important consideration then check the reducer dimension specifications, not all producers make compact units. In fact, working with the right supplier can help you not just find the right gear reducer but also avoid some of the most common mistakes in reducer selection. We provide a free guide to assist you find the appropriate supplier to utilize.

For low and fractional horsepower application you can expect two sizes of worm equipment reducer, the SW-1 and the SW-5. Size and torque output will be the major differences between both of these models. Both feature the hollow or solid result shaft. Both versions are compact and provide users a wide selection of ratios, including:

SW-1, 3.5:1 to 60:1

SW-5, 5:1 to 100:1

Understanding the specifications of your unique application or project is essential to selecting the right worm gearbox.

Precision, 6:1 to 100:1 ratios, torque 1 to 10 Nm and multishaft arrangements

M1, M2, M3

Metric Worm Reduction Gearboxes

Little precision with multi-shaft arrangements

• 6:1 to 100:1

• Torque 1 to 10 Nm

• Drilled and tapped mounting holes at the top and bottom

• Flush fitting bearing caps simple to install

• Input shafts mounted on precision ball bearings

• Max. input speed 10000rpm

• Anti backlash version available

Additional Range:

Neckar Worm Gearboxes Type S – 4 sizes available

Smallest gearbox specifications:

• 5:1 to 60:1

• Output Torque: 1.4-2 Nm

• Aluminium housig

• Special steel worm wheel

• Max. load capacity of output shaft 100N radial, 50N Axial

• Max. input speed 5,000 rpm

• Weight: 0.225kg

Where are Correct Angle Worm Gear Motors Used

Anywhere a compact dual shaft gear motor or single shaft gear motor is necessary. This right angle gear motor is so versatile it can work just about anywhere.

Features & Options

Double Shaft or One Shaft

Hollow Shaft

Maximize Torque in a little Package

Wide Gear Ratio

Cost-Effective

Compact Size

Specifications

Rated Torque: 55.3 – 700 g-cm

Rated Speed: 4710-5900 rpm

Rated Current: 240 – 5500 mA

Gear Ratios: 1:50 – 1:1050

Using miniature gears, Ever-Power provides designed and built exclusive, high accuracy mini gearboxes that cannot be found somewhere else. Our miniature gearboxes can be found in numerous configurations, which includes worm and wheel, cross axis helical, bevel, inline spur, and more. We can also provide custom micro gearboxes that were created and built to meet your unique specifications.

Contact us for the mini gearbox your application requires, or ask for a quote upon a custom micro gearbox.

Micro Gearbox Options

Gearboxes are also called reducers, gear reducers, velocity reducers, gear drives, and gearmotors. All conditions can be used pretty much interchangeably. Please note that the links for our small gear drives include information on the full range of framework sizes for that series or design.

Bevel Box Micro Gear Drive

Our bevel box miniature gear drives are software rated for the ideal balance of overall performance and price. Torque could be balanced to meet your RPM and working life requirements. Light-weight with low backlash functionality (as little as 1°, with option of 1/2”).

Output torque: up to 7 oz.-inches

Low backlash: ≈1°, option of 1/2”

Rated for input speeds up to 2,000 RPM

Temperature range: -5° to 175°F (-20° to 79°C); optional  to -40°F (-40°C)

to -40°F (-40°C)

Cross Axis Helical Miniature Gearbox

Ever-Power miniature cross axis helical gearboxes provide relatively high levels of thrust in a concise package. They offer an output shaft at 90° from the input, and are available in gear ratios from 1:1 to 40:1. Light-weight but durable, with machined aluminum housings and hardened alloy steel gears.

High efficiency: up to 88% at 1,000 RPM

Low backlash: as low as ≤30 arc minutes

Rated for input speeds up to 4,000 RPM

“Left hand” models available

Miniature 2 Shaft Worm Gearbox

Our miniature 2 shaft worm gearmotors are engineered for ≤30 arc moments of backlash or better. Also known as “shaft to bore gearboxes,” the unit provide a single input shaft that protrudes from reverse sides of the casing; output is usually a keyed bore. Regular single- and double-end shafts can be found and supplied with keys and retainer bands. An array of gear ratios and input sizes are available to meet up your needs.

High efficiency: up to 86% at 1,000 RPM

Low backlash: ≤30 arc minutes or better

Available in ratios from 5:1 to 120:1

Rated for input boosts to 3,000 RPM

Miniature 4 Shaft Worm Gearbox

Every miniature 4-shaft worm gearbox from Ever-Power features precision-machined hardened steel gears, solid aluminium housings, and long term lubrication. They offer two insight shafts on opposing sides of the frame, with two output shafts perpendicular to the insight shafts. Our mini 4 shaft worm equipment drives deliver high performance performance with low backlash.

High efficiency: up to 82% at 1,000 RPM

Low backlash: as little as ≈2°

Available with equipment ratios from 1:1 to 32:1

Rated for input boosts to 4,000 RPM

Miniature Flange Worm Gear Drive

These micro flange worm gearboxes create an output at 90° from the insight. They deliver superior functionality in an amazing array applications and are built with small footprints, making them ideal for operations where space is limited. They offer high efficiency with low backlash.

Gear ratios from 6.66:1 to 80:1

High efficiency: up to 83% at 1,000 RPM

Low backlash: as low as ≤4°

Max. input speed: 3,000 PRM

DC motor option available

Miniature Inline Spur Gearbox

Specially engineered for encoder applications, Ever-Power’ micro inline spur gear drives can be found in two frame sizes, and are rated for speeds up to 3,000 RPM. Aluminium housings and stainless steel gears and shafts make these inline spur gearboxes difficult and corrosion resistant, for your most demanding applications.

Result torque: up to 125 oz.-inches

Low backlash: as little as 15 arc minutes

Available with equipment ratios from 4.96:1 to 3600:1

Optional synchro cleats available

Compact Wormwheel Gearbox

These miniature correct angle worm gear reducers deliver superior performance with high efficiency, and show rugged building for challenging power transfer operations. Available in three equipment ratios (5:1, 10:1, 20:1), our small worm gearboxes are built in extremely compact footprints for applications where space is limited.

90° output angle

Gear ratios: 5:1, 10:1, and 20:1

Up to 12.5 inch-lbs. of output torque

Max. input speed: 3,000 RPM

Compact footprint: 1.5” x 1.5” x 1.08”

Custom Miniature Gearbox

Ever-Power may engineer and produce a custom miniature gearbox to meet up your unique specs. We can produce customized micro gearboxes in virtually any configuration your application requires, with result torque levels as high as 900Nm. We can work from your gearbox styles, reverse engineer a preexisting unit, or assist you to develop an all-new style that provides the performance you will need. Demand a quote on a custom miniature gearbox or contact us to discuss your unique requirements.

The Ever-Power Advantage: Little is No Big Problem

Broadest collection of small gear reducers

Greased for life

Ruggedly built

Modifications and special ratios available

Custom small gearboxes designed to suit

Input & Output Shafts

Input and output shafts with drive crucial and retainer rings can be supplied to your specs for just about any of our hollow bore miniature gearboxes. We offer a basic selection of single ended or dual ended shafts to put together in these gearboxes. All gearbox shafts are given keys and retainer bands.

For P and PF series worm and wheel gearboxes make use of our P/PF gearbox shafts.

For E series crossed axis helical gearboxes use our E gearbox shafts.

For F series spur gearboxes, contact our software engineers to discuss your unique needs.

We provide a broad selection of misalignment shaft couplings in in . and metric bore sizes. In . and metric precision surface shafts can be found from stock.

Contact Us for POWERFUL Miniature Gearboxes

We will be the miniature gearbox experts. Our micro gear drive versions deliver superior efficiency in a little footprint, and are tough enough for challenging function environments. E mail us to learn more about our mini gearboxes, or demand a quote on a custom made model that is tailored to your needs.

Additional advantages of worm drive gearboxes include:

We respond to crucial concerns concerning small worm gearbox on our web site.

helical worm gear motor

helical worm gear motor

Helical-worm gearmotors

Due to their design and from being combined with a helical gear stage, the helical-worm gearmotors S..DR.. have particularly high efficiency. They are also extremely low-noise and therefore avoid high sound emission levels.

Low-noise continuous operation: equipment unit combination optimized with respect to efficiency

Do you expect a drive remedy to impress you with its high level of efficiency and efficiency? In that case, we’d recommend our high-quality helical-worm gearmotors EP to you. These can be implemented separately in the modular program. In this manner, they offer you an enormous range of sizes, gear ratios and motor sizes.

However, their greatest strength is their running smoothness and their incredibly low noise development. A very important factor is for certain – With the helical-worm gearmotors EP you are choosing a robust drive solution that you will hardly even hear.

The overall concept also offers you many more practical product characteristics and benefits. Included in these are the significantly higher effectiveness of the helical-worm combinations as opposed to single helical-worm gear products. This is how you save additional energy in the procedure of your systems and are able to noticeably reduce ongoing operating costs.

You will receive the low-noise helical-worm gearmotors EP. – to suit your individual requirements – with a wide range of AC motors. In addition, you can freely configure all the relevant properties. In this manner, you can effectively make use of all the benefits provided by this mixture of low-noise helical-worm gear unit and performance-optimized electric motor. Even greater variance can be achieved because of the optional flange or foot-mounted style and by choosing between solid and hollow shaft.

Save time and money

By opting for one of our gearmotors, you are already saving time and money with this selection and project planning. The reason being our modular system enables a multitude of mixture options for gear products and motors. You can as a result reduce operating costs, depend on an extended service life and benefit from simplified maintenance that’s feature of our brand.

Helical-worm gear units

Helical-worm combinations with considerably better efficiency than single helical-worm gear units

Very low-noise operation

Available variants:

Foot- or flange-mounted

B5 or B14 flange-mounted

Solid or hollow shaft

Hollow shaft with keyed connection, shrink disk, splined hollow shaft, or Ever-Power

More on helical-worm equipment units of series EP

AC motors

Combine the helical-worm equipment unit with this AC motors:

Characteristics

Quiet and reliable transmission of torque

High overload capacity

Hardened steel worm equipment and bronze alloy worm steering wheel provide exceptional strength and lengthy service life.

Optional heavy duty bearings deliver high radial and axial load capacity

High strength cast iron housing (SK02050 – SK43125)

Lightweight, corrosion-resistant aluminium alloy housing (SK02040.1)

Application Specific Solutions

Fields of use

Intralogistics

Material handling

Presses

Version

Solid and Hollow shaft (keyed, shrink disc ) Designs

Available in footed, shaft attach or flange mounted configurations

Right Angled gear units

Your advantages

Economical operation

Low noise

High permitted overhung loads

Helical-worm Gearmotor S Series

S series

Ever-Power helical-worm gear units are helical/helical-worm combinations, so they are more efficient than normal helical-worm gear units. Because of their outstanding efficiency, these drives can be used in every industrial sector and tailored to individual torque and velocity requirements. The decrease ratios afforded by the helical-worm gear stage and the reduced noise levels during procedure make these gearmotors ideal low-cost solutions for simple applications.

Available versions:

Foot-mounted or flange-mounted

B5 or B14 Flange-mounted

Solid or hollow shaft

Hollow shaft with keyed connection, shrink disc, splined hollow shaft

Helical worm geared motors

Tough, compact, eye-catching!

Due to the unique mixture of optimized worm wheel material with unique lubricants, optimized form, this powerful electric motor achieves high levels of effectiveness and torque. The housing machined on all sides allows diverse mounting options. Double chamber shaft seals are utilized as standard.

The reduced contour design makes it suitable for implementing applications e.g. in the food industry. The housing has no recesses, which simplifies cleaning – a particularly important feature for areas with stringent hygiene requirements.

Technical Data

Number of sizes:6

Power Range:0.12 – 7.5kW

Output torque range:50 – 1,300Nm

Ratio:3 – 3,400

Output option:output shaft, output shaft on both sides, hollow shaft, hollow shaft with shrink disc

Assembly/mounting:uniblock, flange, torque arm, foot

Course 12 Helical and hardened and floor worm gears: Provides higher efficiencies and greater torque capacity in smaller sizes.

Multiple Input Options: Essential gear motors, ” or metric shafts, NEMA, IEC, and servo adapters provide unmatched drive versatility.

Multiple Output Choices: Hollow bores and shrink disks for shaft installation, inch and metric output shafts, installation pilots and flanges provide a wide selection of design solutions.

UNIBLOCK Housing: For optimum rigidity universal mounting on five sides or via a torque arm.

Sealed for Washdown: Continues contaminants and water away.

Worldwide Engine: Multiple leads and windings for globally multi volt/Hz requirements in addition modular design to accept brakes, encoders or pressured cooling.

EP equipment motors are economical, right-angle, worm-geared motors that install easily in the tightest applications. Economical correct position worm geared motors established new criteria for reliability, efficiency and economy with unparalleled features which includes hollow shafts in the smallest sizes. An inverter friendly design provides for easy integration today and a really future proof option. The EP gear engine offers total flexibility in mounting options includes shaft, base, face, and flange solutions. The electric motor terminal box could be mounted in substitute positions rotated in 90º steps around the motor frame offering for unparalleled integration options.

EP gear motors adhere to UNITED STATES and International specifications, including NEMA, IEC, CSA, and CE, the EP series permits worldwide acceptance, a true total answer for our global clients.

Excellent protection of IP65 acc. to IEC 529 assures you that the EP series is usually dirt tight and hose proof,and can be utilized outdoors or in wet and dusty conditions without the use of additional enclosures. Complete rated output is offered by the result shaft of the machine.

Product Features

Power ranking up to 5,5 kW.

Torque 25 … 1.000 Nm

Output Speeds 0,2 … 300 min-1

versatile installation possibilities

Completely enclosed, sealed against dust and water spray

Lubrication change initial after 15000 hrs

Low noise gearing

Mains connection 110 … 690V, 50/60Hz

Enclosure IP65 (Regular), IP66 (Optional)

Connection Standard with CAGE CLAMP®

Additional features:

Connecting with Plug connectors.

With integrated inverter up to 7,5kW.

EP-Mark

CSA, UL, ATEX, GOST, CCC, ISO9001, ISO14001, OHSAS18001

Motors according to Sobre 60034

Corrosion category predicated on DIN ISO 12944-5

C1, C2, C3, C4, C5-I, C5-M

Due to the unique combination of optimized worm wheel materials with unique lubricants and optimized shape, this powerful geared motor achieves high degrees of performance and torque. The low contour design makes it suitable for implementing applications electronic.g. in the meals industry. The housing does not have any recesses, which simplifies cleaning – an especially important feature for areas with stringent hygiene requirements.

Nominal torque: 50 – 1300 Nm

Rated power: 0.12 – 7.5 kW

Ratio: 3 – 3400

The 800BR contains a wide selection of compact, durable helical gear drives with extended life performance features and simplified maintenance. The use of condition of the artwork helical and worm equipment combinations affords optimum functionality fulfilling a multitude of ratio requirements. The 800 BR can be functionally interchangeable with most major manufacturer’s drives.

SPECIFICATIONS

Dual and triple reduction ratios from 8:1 to 900:1,

4 case sizes – 830, 840, 850, 860

All models shipped pre-lubed for your particular installation position with KluberSYNTH UH1 6-460

Obtainable in NEMA C-face flanged and direct input

Projecting and hollow result shafts

Available accessories

Output flange kits

Torque arm kits

Base kits

Output shaft kits

Product Features

Available in nontoxic white-colored (BK) and stainless epoxy finish (SBK)

Obtainable in hollow or projecting output shafts

Dual and triple reduction ratios

Flanged or foot mounted

All systems adaptable to ground, sidewall or ceiling mounting

Helical worm geared motor

0,12 – 5,5 kW

4 – 996 Nm / 6 – 316 rpm

Stober MGS S helical worm geared motor

Efficient small right-angle geared motor. A favorably priced option for the standard jobs expected of a right-angle drive.

5 gear sizes (S0 to S4).

Engine power 0.12 to 5.5 kW.

Rated torque of 23 to 800 Nm.

Gear ratios from we  = 6 to 680.

= 6 to 680.

Backlash smaller than 20 arcmin.

Modular, torsionally stiff , leak-proof design.

Helical worm geared motors available with:

Solid shaft with keyway.

Hollow shaft with keyway, optional with cover.

Hollow shaft with shrink disk, optional with cover.

Gear device and AC electric motor are directly flange mounted, the pinion is upon the motor shaft. This integrated small design is an essential factor for the high accuracy and the remarkable stiffness of EP geared motors.

For vector-controlled inverter operation utilization of an incremental encoder is provided for as regular.

Worm gearboxes and helical worm gearboxes / geared motors (S and SS)

The amount of efficiency in Ever-Power high performance worm gearboxes and helical worm gearboxes is more than 90%. All worm shafts are made from case hardened alloy steel and the flanks are precision floor. The worm wheels are made from unique wear-resistant bronze. Helical worm gears are equipped with a helical gear. Worm gears with shrink disc, torque limiter, along with adjustable backlash styles are also component of our standard product range.

Worm gearboxes and helical worm gearboxes type S and SS are high-Overall performance gearboxes in universal design. The housings are made from high quality cast iron. The rugget wall space and internal ribbing ensure incredibly torsional stiff and noise dampening housings. The exterior ripping offers a rapid heat conducting.

Type S und SS

Technical characteristics:

Optimised size/performance ratio

Designed for permanent operation under rough circumstances

Above average lifespan

Housing produced from high quality grey cast iron with rugged walls and internal ribbing

Severe torsional resistance and low noise

Case hardened worm shafts and worms with precision floor flanks

Worm wheels produced from unique bronze

Superior smooth operation

Space saving angular drive

Helical worm gearboxes built with helical gear wheel

Low engine speeds

Options:

Basic mounting, flange mounting or universal design

Output shaft available as solid shaft or hollow shaft

Shrink disc, torque limiter,in addition to adjustable backlash

Second shaft end for fitting encoders or brakes

Torque arm

IEC-adaptor

NEMA version

Free input shaft

ATEX specification according to directive 94/9/EG

helical worm gear motor, the right choice for you.

compact worm gearbox

Request Custom or

Modified Product

gearbox-PR5

Working with miniature gears, Ever-Power has designed and built unique, high accuracy mini gearboxes that can’t be found anywhere else. Our miniature gearboxes are available in numerous configurations, including worm and wheel, cross axis helical, bevel, inline spur, and extra. We are able to also provide customized micro gearboxes that were created and created to meet your specific specifications.

E mail us for the mini gearbox the application requires, or request a quote upon a customized micro gearbox.

Miniature Bevel Gearboxes | Micro Bevel Equipment Drives | Mini Bevel Gearboxes

Bevel Box

Miniature Cross Axis Helical Gearboxes | Cross Axis Helical Mini Gear

Cross Axis Helical

Miniature Shaft-to-Bore Worm Gearboxes and also Speed Reducers

Shaft-to-Bore

Miniature 4 Shaft Worm Gearboxes | Mini 4 Shaft Worm Gear Motors

4 Shaft Worm

Miniature Flange Worm Gearboxes | Micro Flange Worm Equipment Drives

Flange Worm

Miniature Inline Spur Gearboxes | Micro Inline Spur Acceleration Reducers

Inline Spur

Compact Worm

Compact Worm

Micro Gearbox Options

Gearboxes are also known as reducers, gear reducers, acceleration reducers, gear drives, and gearmotors. All terms can be used pretty much interchangeably. Please be aware that the links for our little gear drives include info on the full selection of frame sizes for that series or design.

Bevel Box Micro Equipment Drive

Our bevel package miniature equipment drives are application rated for the ideal balance of overall performance and cost. Torque can be balanced to meet up your RPM and operating life requirements. Light-weight with low backlash performance (less than 1°, with choice of 1/2”).

Result torque: up to 7 oz.-inches

Low backlash: ≈1°, option of 1/2”

Rated for input boosts to 2,000 RPM

Temperature vary: -5° to 175°F (-20° to 79°C); optional to -40°F (-40°C)

Cross Axis Helical Miniature Gearbox

Ever-Electric power’ miniature cross axis helical gearboxes provide relatively high amounts of thrust in a compact package. They provide an result shaft at 90° from the input, and so are available in equipment ratios from 1:1 to 40:1. Light-weight but durable, with machined aluminium housings and hardened alloy metal gears.

Excessive efficiency: up to 88% at 1,000 RPM

Low backlash: as low as ≤30 arc minutes

Rated for input speeds up to 4,000 RPM

“Left hand” models available

Miniature 2 Shaft Worm Gearbox

Our miniature 2 shaft worm gearmotors are engineered for ≤30 arc minutes of backlash or better. Also known as “shaft to bore gearboxes,” the unit provide a single insight shaft that protrudes from opposite sides of the housing; output is a keyed bore. Standard single- and double-end shafts can be found and given keys and retainer bands. An array of gear ratios and insight sizes are offered to meet up your needs.

High efficiency: up to 86% at 1,000 RPM

Low backlash: ≤30 arc minutes or better

Available in ratios from 5:1 to 120:1

Rated for input boosts to 3,000 RPM

Miniature 4 Shaft Worm Gearbox

Every miniature 4-shaft worm gearbox from Ever-Power features precision-machined hardened steel gears, solid aluminium housings, and long lasting lubrication. They offer two input shafts on opposite sides of the body, with two output shafts perpendicular to the input shafts. Our mini 4 shaft worm equipment drives deliver high efficiency overall performance with low backlash.

High efficiency: up to 82% at 1,000 RPM

Low backlash: as little as ≈2°

Available with equipment ratios from 1:1 to 32:1

Rated for input boosts to 4,000 RPM

Miniature Flange Worm Gear Drive

These micro flange worm gearboxes create an output at 90° from the insight. They deliver superior performance in an amazing array applications and are built with little footprints, making them well suited for procedures where space is limited. They offer high efficiency with low backlash.

Gear ratios from 6.66:1 to 80:1

Huge efficiency: up to 83% at 1,000 RPM

Low backlash:  as low as ≤4°

as low as ≤4°

Max. input speed: 3,000 PRM

DC motor option available

Miniature Inline Spur Gearbox

Specially engineered for encoder applications, Ever-Power micro inline spur gear drives can be found in two frame sizes, and are rated for boosts to 3,000 RPM. Light weight aluminum housings and stainless gears and shafts get these inline spur gearboxes challenging and corrosion resistant, for your the majority of demanding applications.

Result torque: up to 125 oz.-inches

Low backlash: less than 15 arc minutes

Available with gear ratios from 4.96:1 to 3600:1

Optional synchro cleats available

Compact Wormwheel Gearbox

These miniature correct angle worm gear reducers deliver excellent performance with high efficiency, and show rugged structure for challenging power transfer functions. Available in three equipment ratios (5:1, 10:1, 20:1), our compact worm gearboxes are built in extremely compact footprints for applications where space is limited.

90° output angle

Gear ratios: 5:1, 10:1, and 20:1

Up to 12.5 inch-lbs. of output torque

Max. input speed: 3,000 RPM

Compact footprint: 1.5” x 1.5” x 1.08”

Custom Miniature Gearbox

Ever-Power can engineer and manufacture a custom miniature gearbox to meet up your unique standards. We can produce customized micro gearboxes in practically any configuration your application requires, with output torque levels as high as 900Nm. We are able to work from your gearbox styles, reverse engineer a preexisting unit, or help you develop an all-new design that provides the performance you need. Request a quote on a customized miniature gearbox or e mail us to discuss your unique requirements.

The Ever-Power Advantage: Small is No Big Problem

Broadest selection of small gear reducers

Greased for life

Ruggedly built

Modifications and particular ratios available

Custom small gearboxes made to suit

Input and also Output Shafts

Input and result shafts with drive important and retainer rings can be supplied to your specifications for any of our hollow bore miniature gearboxes. We offer a basic collection of single ended or double ended shafts to assemble in these gearboxes. All gearbox shafts are given keys and retainer bands.

For P and PF series worm and wheel gearboxes use our P/PF gearbox shafts.

For E series crossed axis helical gearboxes use our Electronic gearbox shafts.

For F series spur gearboxes, contact our program engineers to discuss your unique needs.

We provide a broad selection of misalignment shaft couplings during ” and metric bore sizes. ” and metric precision surface shafts are available from stock.

Die-cast zinc housing – Various models for hands operation

Compact Worm Gearboxes

4731 to 4742, 4746 to 4767

Perfect for use with crank handle

Main physical dimensions:

P/N 4731 to 4742 40mm x 40mm x 70mm

P/N 4747 to 4767 17mm x 35mm x 42mm

Wide range of ratios from 1:1 to 30:1

1:1, 2:1 and 2.8:1 aren’t self locking, all the ratios are.

Max. output torques: 2 Nm to 17 Nm

Hand operation only

Direct coupling between servo electric motor and worm gear is one of the crucial strengths of EP worm gearmotors, which merge DC engine technology with exceptional toughness and wear resistance. Motor and gearbox are designed as one single, compact unit. Thanks to their reduced current draw, these gearmotors deliver even more accurate control of working temperature and higher effectiveness.

45 W to 250 W rated output power

Gearbox centre-centre size 31 mm and 33 mm

Aluminium gearbox casing

Case-hardened, tempered and ground worm

Great tin bronze worm gear

Steel shaft planetary gearboxes

Case-hardened and tempered steel gears

Low noise Selection of coupling flanges

We deliver worm gearboxes, spur gearboxes and planetary gearboxes with or without integrated linear lead screw / ball screw adapted to our flexible modular concept.

Based at this we are able to select a wide selection of ordinary customizations to meet up the requirements of varied properties that are essential for each application.

If your application takes a gearbox with some special home such as for example small dimensions or low weight in relation to electrical power, high efficiency, quiet and vibration-free operation, extended life, high level of resistance to vibration, pressure or temperature, integrated linear screw, or a mixture of such properties, our item range with more than 1000 different standard gearboxes is probably an excellent start to be able to deliver something that stands out on your side.

Small gearboxes are high-top quality gearboxes for standard drives. The electric electric motor is included with the gearbox into a single device (the first gear is on the electric motor shaft). Individual gearboxes for link with conventional IEC motors can also be supplied on request.

Because of the complexity of the gearboxes’ configuration, they can not be purchased in our e-shop. Our specialists will be pleased to help you create your selection. We will be happy to send you documentation or style the right set directly, on demand.

VANE MOTORS WITH GEARBOXES

Combinations feasible with all our vane motors

Coaxial gearbox

Planetary gearbox

Worm gearbox

ATEX combinations possible

Stainless options possible

Special wishes possible

Ever-Power worm gearboxes possess earned a status to be a business benchmark worldwide. Our success originated from our relentless travel for level of quality with state-of-the-artwork technology, all and will be offering worm gearboxes will be affordable prices. High flexibility accorded through a broad choice of mounting options, shaft configurations and motor interfaces, produces the Ever-Electricity worm gearbox the default choice for the sector. The helical-worm and the double-worm edition, with or without the torque limiter, soon add up to the advantage, creating a highly versatile drive system.

Ever-Ability Worm gearboxes provide great torque with low acceleration gear ratio. Being basic and compact in design, these gears can achieve higher gear ratio than the helical gears. These worm reduction gears having screw type qualities act like helical gears, but its helix angle is typically comparatively bigger) and its body is generally quite lengthy in the axial path. The gears in these gearboxes could be best or left-handed depending upon the purpose.

Mounting option include universal housing, side flanges, foot (horizontal and vertical), shaft mounted with torque arm. Available in Solid shafts (single or dual), with torque arm or torque limiter.

EXCELLENT Geared Motors. Ever-Vitality gearboxes and geared motors are the electro-mechanical key elements for low backlash, efficiently running and highly powerful drive systems.

Our high-performance gear devices are built to withstand the toughest industrial applications.

The gear housings are machined on all sides and permit diverse installation positions and applications, producing them much popular in the industry. As a result our geared motors are often to be found as part of our customers own machines.

The smooth running of Ever-Power gear units and the outstanding load capacity of WATT teeth are achieved with 3D design supported simply by FEM (Finite Element Method). This tooth geometry ensures optimum rolling get in touch with under load.

The special tooth root design in mixture with tooth helix angle, tooth depth, the components used and surface finish maximizes load capacity. This huge gearing capacity enables smaller wheels to be utilized for the exact torque, and smaller sized gears with excellent power density also increase reliability. Ever-Power geared motors are therefore incredible space savers.

Gearing manufactured with such micro-geometric precision allows the gearing enjoy required for troublefree rolling contact to be substantially reduced and therefore the gear backlash to end up being minimized.

Dual chamber shaft seals developed by Ever-Power are utilized as standard for parallel shaft, shaft mounted and helical worm gears for a higher level of tightness.

Ever-Power’s modular gear technology meets certain requirements of advanced drive programs:

Excellent power density

Minimum backlash

Smooth running

Diverse mounting options

Maximum reliability

High variability

Precision Worm Gearboxes plus Geared Motors

EP’s precision worm gearboxes are designed for those more demanding applications where small size, high torque, high ratio, low backlash, low noise and long life time are required. Offered in 9 sizes, these worm gearboxes could be supplied with totally free insight shaft, with hollow bore insight shaft and electric motor flange, and double reduction mixture units for slow acceleration applications. By using cast iron housings, high quality bronze alloy worm tires and long life bearings, reliability and functionality are the key top features of this range.

High Precision Right Position Transmission

Long Lifetime

WIDE RANGE Of Ratios

Special Surface Treatments

Compact Worm Gearbox has provided dispute in the past weeks; the good news is, at https://www.ever-power.net/product/compact-worm-gearbox/, we analyze every aspect of the topic to ensure you have a clear point of view of the issue.

worm drive servo

This standard selection of Servo-Worm Reducers are ideal for use in applications that demand powerful, precise positioning and repeatability. These were particularly developed for use with state-of-the-art servo electric motor technology, providing tight integration of the motor to the unit. Angular backlash of less than 1 arc-a few minutes is provided standard.

They are available in four sizes (50 mm to 100 mm center distance) with input boosts to 5,000 rpm, reduction ratios from 4.75 to 52:1 and output torque capacities up to 885 lb.ft. A wide range of engine couplings and installation flanges are available for assembly to practically all servo motors, and the hollow bore output can be utilized to mount output shafts, pinion shafts, or other drive elements.

Normal applications for these reducers include precision rotary axis drives, traveling gantries & columns, materials handling axis drives, zero-backlash axis drives and digital line shafting. Industries served include Material Managing, Automation, Aerospace, Machine Tool and Robotics.

helical-worm servo gearmotors possess a torque range of 92 Nm to 520 Nm. As angular drives they are especially space-saving and decrease the expenditure for precious installation space.

The helical-worm servo gearmotors are designed so that they guarantee you a low-noise system environment. Moreover, these gearmotors offer you excellent attenuation properties for the operation of your systems with low levels of vibration. This can be due to the longitudinal app of drive on the input shaft. This allows torque impulses to become prevented successfully and for optimum results when it comes to running smoothness and sound reduction to be performed.

Both the gear unit, and the synchronous servomotor  derive from our modular system. This allows you to have fully individual configuration possibilities for each application. One thing is for certain – Our servo gearmotors are real specialists for very particular requirements.

derive from our modular system. This allows you to have fully individual configuration possibilities for each application. One thing is for certain – Our servo gearmotors are real specialists for very particular requirements.

Wormwheel gearboxes pass several names, including 90-degree gearboxes, right angle gearboxes, velocity reducers, worm equipment reducers and worm drive gearboxes. Gear reduction boxes feature a gear arrangement when a equipment in the type of a screw, also called a worm, meshes with a worm gear. These gears are usually made from bronze and the worms are metal or stainless steel.

While worm gears are similar to a spur gear, the worm gearboxes are considerably smaller than other gear reduction boxes. A primary benefit of worm gear reducers can be that they create an output that is 90° from the input and can be utilized to transmit higher torque or decrease rotational speed. Frequently, a worm gearbox offers right hands threads; to improve the path of the output, a left-hand thread worm gearbox is required.

Sometimes a motor’s capability could be limited to the point where it requires gearing. As servo manufacturers develop better motors that can muscle applications through more complicated moves and generate higher torques and speeds, these motors require gearheads equal to the task.

What else would certainly you like to know about Worm Drive Servo?

Single Start Worm

As a result of friction, some designers will pick a worm gear match to act because a brake to prohibit reversing motion in their mechanism. This idea develops from the concept that a worm gear pair becomes self-locking when the lead angle is definitely tiny and the coefficient of friction between the materials is large. Although not an absolute, when the lead angle of a worm gear pair is significantly less than 4 degrees and the coefficient of friction is usually higher than 0.07, a worm equipment pair will self-lock.

Since worm gears have a lead angle, they do create thrust loads. These thrust loads vary on the course of rotation of the worm and the way of the threads. A right-hand worm will pull the worm wheel toward itself if managed clockwise and will press the worm wheel away from itself if operated counter-clockwise. A left-hand worm will act in the specific opposite manner.Worm equipment pairs are an excellent design choice if you want to lessen speeds and transform the directions of your movement. They can be purchased in infinite ratios by changing the amount of tooth on the worm wheel and, by changing the lead angle, you can modify for every center distance.

First, the fundamentals. Worm gear models are being used to transmit vitality between nonparallel, nonintersecting shafts, usually having a shaft angle of 90 degrees, and consist of a worm and the mating member, known as a worm wheel or worm equipment. The worm has teeth covered around a cylinder, similar to a screw thread. Worm gear models are generally used in applications where in fact the speed lowering ratio is between 3:1 and 100:1, and in situations where accurate rotary indexing is required. The ratio of the worm set depends upon dividing the amount of the teeth in the worm wheel by the amount of worm threads.

The direction of rotation of the worm wheel depends after the direction of rotation of the worm, and whether the worm teeth are cut in a left-hand or right-hand direction. The hands of the helix is the same for both mating customers. Worm gear models are made so that the main one or both associates wrap partly around the various other.

Single-enveloping worm gear models own a cylindrical worm, with a throated equipment partly wrapped around the worm. Double-enveloping worm gear sets have both participants throated and covered around one another. Crossed axis helical gears aren’t throated, and so are sometimes known as non-enveloping worm gear pieces.

The worm teeth may have various forms, and so are not standardized in the way that parallel axis gearing is, but the worm wheel will need to have generated teeth to produce conjugate action. One of the qualities of a single-enveloping worm wheel is usually that it’s throated (see Figure 1) to boost the contact ratio between the worm and worm wheel pearly whites. This ensures that several the teeth are in mesh, posting the strain, at all situations. The result is increased load ability with smoother operation.

In operation, single-enveloping worm wheels have a line contact. As a tooth of the worm wheel passes through the mesh, the contact line sweeps across the whole width and height of the zone of actions. One of the characteristics of worm gearing is usually that the teeth have an increased sliding velocity than spur or helical gears. In a low ratio worm gear set, the sliding velocity exceeds the pitch collection velocity of the worm. Although static capacity of worms is substantial, in part due to the worm set’s high speak to ratio, their operating potential is limited as a result of heat made by the sliding tooth contact action. As a result of have on that occurs because of this of the sliding action, common factors between your number of the teeth in the worm wheel and the amount of threads in the worm ought to be avoided, if possible.

Due to relatively great sliding velocities, the general practice is to produce the worm from a material that is harder than the materials selected for the worm wheel. Products of dissimilar hardness are less inclined to gall. Mostly, the worm gear set includes a hardened metal worm meshing with a bronze worm wheel. Selecting the particular kind of bronze is structured upon careful consideration of the lubrication system used, and additional operating circumstances. A bronze worm wheel can be more ductile, with less coefficient of friction. For worm models operated at low swiftness, or in high-temperature applications, cast iron may be used for the worm wheel. The worm undergoes many more contact pressure cycles compared to the worm wheel, so it is advantageous to utilize the harder, more durable material for the worm. A detailed evaluation of the application may indicate that additional materials combinations will perform satisfactorily.

Worm gear sets are sometimes selected for make use of when the application requires irreversibility. This signifies that the worm can’t be driven by electric power applied to the worm wheel. Irreversibility occurs when the lead angle is add up to or significantly less than the static angle of friction. To prevent back-driving, it is generally necessary to use a lead angle of no more than 5degrees. This characteristic is probably the causes that worm gear drives are commonly found in hoisting apparatus. Irreversibility provides proper protection in the event of a power failure.

It is important that worm gear housings be accurately manufactured. Both 90 degrees shaft position between your worm and worm wheel, and the center distance between the shafts are critical, so that the worm wheel the teeth will wrap around the worm properly to maintain the contact routine. Improper mounting conditions may create point, rather than line, contact. The resulting high product pressures could cause premature failure of the worm established.

How big is the worm teeth are commonly specified in conditions of axial pitch. This is actually the distance in one thread to the next, measured in the axial plane. When the shaft position is 90 degrees, the axial pitch of the worm and the circular pitch of the worm wheel are equal. It is not uncommon for great pitch worm sets to really have the size of the teeth specified when it comes to diametral pitch. The pressure angles applied depend upon the business lead angles and should be large  enough to prevent undercutting the worm wheel tooth. To provide backlash, it really is customary to slim one’s teeth of the worm, but not the teeth of the worm equipment.

enough to prevent undercutting the worm wheel tooth. To provide backlash, it really is customary to slim one’s teeth of the worm, but not the teeth of the worm equipment.

The standard circular pitch and normal pressure angle of the worm and worm wheel must be the same. Because of the selection of tooth varieties for worm gearing, the normal practice is to establish the type of the worm tooth and then develop tooling to produce worm wheel teeth having a conjugate profile. Because of this, worms or worm tires having the same pitch, pressure angle, and number of tooth are not necessarily interchangeable.

A worm gear assembly resembles a single threaded screw that turns a modified spur equipment with slightly angled and curved teeth. Worm gears could be fitted with the right-, left-hands, or hollow output (drive) shaft. This right position gearing type is utilized when a large speed decrease or a huge torque increase is required in a limited amount of space. Figure 1 shows a single thread (or single start off) worm and a forty tooth worm gear producing a 40:1 ratio. The ratio is equal to the amount of gear pearly whites divided by the amount of starts/threads on the worm. A comparable spur gear collection with a ratio of 40:1 would require at least two phases of gearing. Worm gears can achieve ratios greater than 300:1.

Worms can end up being made out of multiple threads/starts as proven in Body 2. The pitch of the thread remains frequent as the lead of the thread increases. In these good examples, the ratios relate to 40:1, 20:1, and 13.333:1 respectively.

Bodine-Gearmotor-Body 2- Worm GearsWorm equipment sets can be self-locking: the worm may drive the gear, but as a result of inherent friction the gear cannot turn (back-travel) the worm. Typically simply in ratios above 30:1. This self-locking action is reduced with put on, and should never be used as the principal braking system of the application.

The worm equipment is normally bronze and the worm is metal, or hardened steel. The bronze component is made to wear out before the worm since it is much easier to replace.

Lubrication

Proper lubrication is particularly crucial with a worm equipment collection. While turning, the worm pushes against the strain imposed on the worm equipment. This effects in sliding friction as compared to spur gearing that makes mostly rolling friction. The ultimate way to lessen friction and metal-to-metal wear between your worm and worm equipment is by using a viscous, temperature compound gear lubricant (ISO 400 to 1000) with additives. While they prolong lifestyle and enhance functionality, no lubricant additive can indefinitely prevent or overcome sliding put on.

Enveloping Worm Gears

Bodine-Gearmotor-Enveloping-Worm-Gear-with-Contoured-TeethAn enveloping worm equipment set should be considered for applications that require very accurate positioning, excessive efficiency, and minimal backlash. In the enveloping worm equipment assembly, the contour of the gear tooth, worm threads, or both happen to be modified to improve its surface get in touch with. Enveloping worm gear models are less prevalent and more costly to manufacture.

Do your research study … you’ll locate people are totally pleased with Single Start Worm.

worm gear components

EP specializes in plastic-type gears. Molded and machined plastic-type gears can be found in both inches and metric sizes. A wide range of various configurations, number of tooth and sizes are available. Standard catalog products include spur gears, equipment racks, bevel gears, miter gears, flexiracks and pinions, and worm gear pieces. If a standard component does not meet your needs, modifications or personalized parts could be designed, designed and manufactured to your precise requirements.

Metric Gears

ISO 12, 10, 9, and 8

Offered Modules: 120 thru 16

Pressure Angles: 20° and 14.5°

Spur Gears

Inch Gears

AGMA 12, 10, 9, and 8

Obtainable Pitches: 120  thru 16

thru 16

Pressure Angles: 20° and 14.5°

EP applies strict quality control throughout the whole manufacturing cycle. Comprehensive engineering experience enables us to offer the additional services of style review and / or value engineering toward the purpose of manufacturing effectiveness. An on-site Class 10000 clean space is used for screening, assembly and packaging. EPS and consumer approved facilities are used for casting, high temperature-dealing with, plating, and painting. We can machine in many materials including lightweight aluminum, brass, bronze, steel alloys, stainless steel and titanium.

SDP/SI is a well-known manufacturer of great precision standard and custom gears for an array of applications. Our good to channel pitch gears are manufactured for some of the very most demanding customers in the aerospace, defense, and medical industries of today.

Have you or participants of your family members taken into consideration worm gear components?

metric worm gears

Worm & Wormwheels

Request Custom or

Modified Product

Worms & Worm Gears | Wormwheels

16, 24, 32, 48 or 64 Diametral Pitch

Worm and Worm Gears units transfer motion between nonintersecting right angle shafts. They are the most compact little precision gears system offered, along with the quietest and smoothest working. A worm and worm gears placed can provide a higher reduction ratio in an exceedingly small space.

EP has been developing worm  and wheel gear systems for over 30 years. You can expect worms and worm gears units in various inches and metric sizes and with various pitch, tooth count, and hub alternatives. Our precision ground stainless worm and wheels and phosphor bronze worm gears provide the best accuracy, smoothest procedure, and longest working lifestyle.

and wheel gear systems for over 30 years. You can expect worms and worm gears units in various inches and metric sizes and with various pitch, tooth count, and hub alternatives. Our precision ground stainless worm and wheels and phosphor bronze worm gears provide the best accuracy, smoothest procedure, and longest working lifestyle.

Order a worm and wheel system for your application, request a quote, or get in touch with EP to learn more.

EP’ POWERFUL Worm Gear Systems

A worm is configured much like a equipment screw, but with teeth designed to mesh with the teeth of a worm wheel. These tiny precision gears may have one or multiple threads (known as begins). With each revolution, a single-start worm will approach the affiliated worm wheel by one tooth; worms with multiple begins will maneuver the mating worm equipment a corresponding amount of the teeth with each revolution. (e.g., a 2-begin worm will move it is worm wheel two tooth per revolution.)

Standard worm equipment worm wheels feature directly, helical-cut teeth and provide only 1 point of connection with the worm. EP provides “throated” worm wheels with curved, helical-cut the teeth whose curves meet the radius of the worm itself. Throated worm tires provide a much greater speak to area, which vastly enhances load capacity and longevity.

Extra details about metric worm gears can be found on our web site.